Method for producing feruloyl esterase

A ferulic acid esterase and production method technology, applied in the field of biological enzyme preparations, can solve the problems of difficult enzyme extraction and purification, low yield of ferulic esterase, unstable product quality, etc., shorten the production cycle, reduce Production cost and operation cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

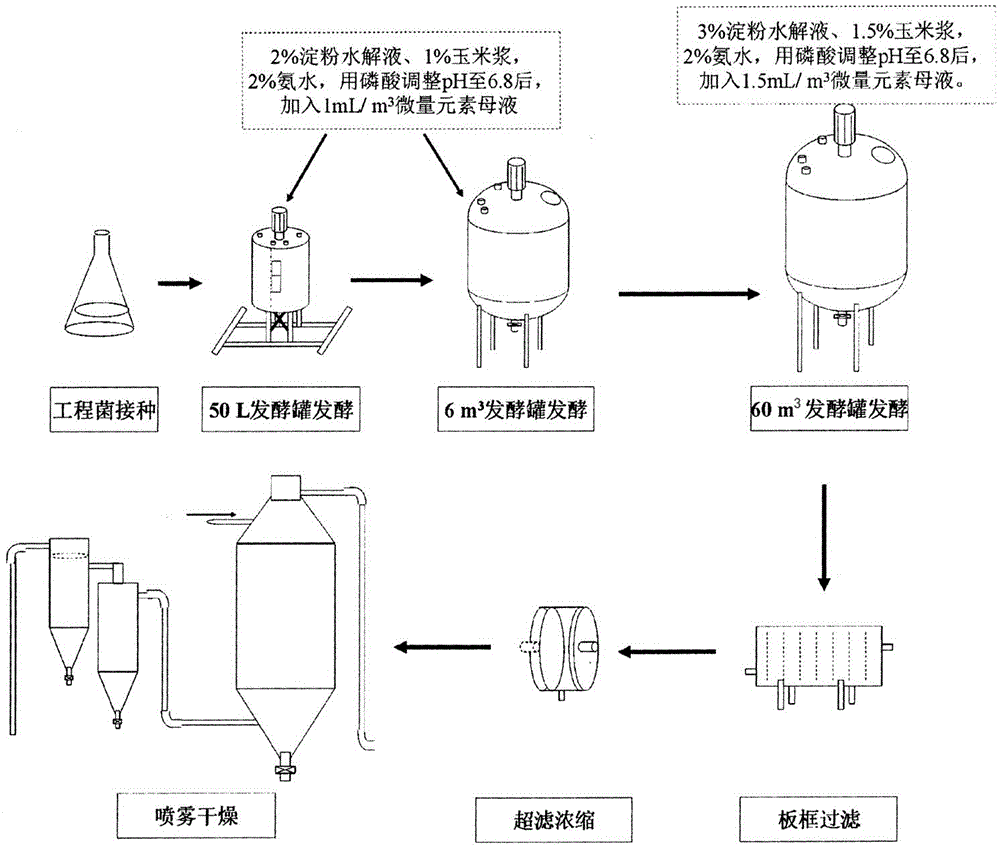

Image

Examples

Embodiment 1

[0026] (1) Strain preparation:

[0027] (1.1) Inoculate 1% by weight of the Pichia pastoris strain constitutively expressing ferulic acid esterase A into 500mL of sterilized medium, cultivate it at 28°C and 220 rpm for 60 hours, and use it as a seed solution for later use; The medium is composed of the following raw materials in mass percentage: 1% yeast powder, 2% peptone, 2% glucose, and the balance is water;

[0028] (1.2) Prepare 30 L of sterilized medium in a 50 L fermenter: take industrial-grade raw materials according to mass percentage: 2% starch hydrolyzate, 1% corn steep liquor, 2% ammonia water, and the balance is water; adjust the pH with phosphoric acid After reaching 6.8, add 1mL / m 3 Trace element mother liquid, sterilized at 124°C for 30 minutes, and used as seed liquid culture medium for later use;

[0029] (1.3) Transfer the seed solution prepared in step (1.1) into the 50L fermenter prepared in step (1.2) containing 30 L of sterilized medium, and cultivate ...

Embodiment 2

[0039] (1) Strain preparation:

[0040] (1.1) Inoculate 1% by weight of the Pichia pastoris strain constitutively expressing ferulic acid esterase A into 500mL of sterilized medium, cultivate it at 28°C and 200 rpm for 48 hours, and use it as a seed solution for later use; The medium is composed of the following raw materials in mass percentage: 1% yeast powder, 2% peptone, 2% glucose, and the balance is water;

[0041] (1.2) Prepare 30 L of sterilized medium in a 50 L fermenter: take industrial-grade raw materials according to mass percentage: 2% starch hydrolyzate, 1% corn steep liquor, 2% ammonia water, and the balance is water; adjust the pH with phosphoric acid After reaching 6.8, add 1mL / m 3 Trace element mother liquid, sterilized at 120°C for 30 minutes, and used as seed liquid culture medium for later use;

[0042] (1.3) Transfer the seed solution prepared in step (1.1) into the 50L fermenter prepared in step (1.2) containing 30 L of sterilized medium, and cultivate ...

Embodiment 3

[0052] (1) Strain preparation:

[0053] (1.1) Inoculate 1% by weight of Pichia pastoris strains constitutively expressing ferulic acid esterase A into 500mL of sterilized medium, cultivate them at 30°C and 240 rpm for 60 hours, and use them as seed liquid for later use; The medium is composed of the following raw materials in mass percentage: 1% yeast powder, 2% peptone, 2% glucose, and the balance is water;

[0054] (1.2) Prepare 30 L of sterilized medium in a 50 L fermenter: take industrial-grade raw materials according to mass percentage: 2% starch hydrolyzate, 1% corn steep liquor, 2% ammonia water, and the balance is water; adjust the pH with phosphoric acid After reaching 6.8, add 1mL / m 3 Trace element mother liquid, sterilized at 121°C for 30 minutes, and used as seed liquid culture medium for later use;

[0055] (1.3) Transfer the seed solution prepared in step (3.1) into the 50L fermenter prepared in step (3.2) containing 30 L of sterilized medium, and cultivate at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com