Polyvinyl alcohol sponge and preparation method thereof

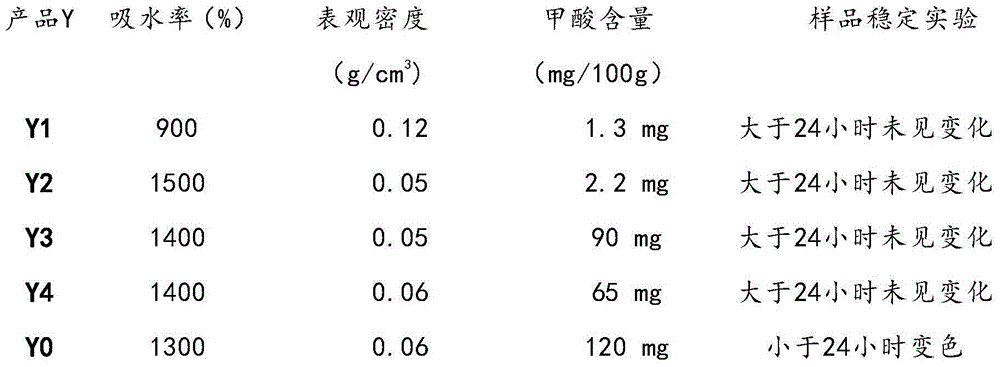

A technology of polyvinyl alcohol sponge and polyvinyl alcohol solution, applied in coating and other directions, can solve the problems of reducing the life of sponge products, denaturation of sponge materials, and degradation of sponge performance, etc., and achieves the effects of fine hand feeling, reduction of residues, and improvement of yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] (a) preparing a polyvinyl alcohol solution, stirring 15 parts of polyvinyl alcohol in 200 parts (by weight) of water at a temperature of 60-80°C to form a polyvinyl alcohol solution;

[0085] (b) Prepare the foaming solution: take 100g of the polyvinyl alcohol solution prepared in step (a), blow carbon dioxide gas into the system for 5-10 minutes, keep the carbon dioxide gas atmosphere, heat to 40-50°C, and control the stirring speed to 1000 -1300 rpm, stirring for 20-30 minutes;

[0086] (c) Acetal reaction, keep the carbon dioxide gas atmosphere, control the stirring speed at 800-900 rpm, add 15g of hydrochloric acid, stir for 10-20 minutes, add 15g of formaldehyde, reduce the stirring speed to 700-800 rpm, stir for 10- After 30 minutes, add 0.3g of foam stabilizer OP-10, and gradually reduce the stirring speed until the stirring stops, the process is about 5-10 minutes.

[0087] (d) Curing molding: Pour the slurry stirred in (c) into the mold after carbon dioxide re...

Embodiment 2

[0090] (a) Prepare a polyvinyl alcohol solution, under the condition of nitrogen protection, stir 10 parts of polyvinyl alcohol in 200 parts (by weight) of water at a temperature of 60-80°C to form a polyvinyl alcohol solution;

[0091] (b) Prepare the foaming solution: Take 100kg of the polyvinyl alcohol solution prepared in step (a), add it to a reaction kettle filled with nitrogen, heat it to 40-50°C, control the stirring speed at 600-700 rpm, add the foaming Agent AC (azodicarbonamide) 0.5kg, stir for 5-10 minutes, add dispersant 1kg; stir for 5-20 minutes;

[0092] (c) Acetal reaction, in a nitrogen atmosphere, control the stirring speed at 700-1200 rpm, add 10 kg of hydrochloric acid, stir for 10-20 minutes, add 12 kg of formaldehyde, reduce the stirring speed to 400-500 rpm, stir for 10- After 30 minutes, add 0.3kg of foam stabilizer OP-10, and gradually reduce the stirring speed until the stirring stops, the process is about 5-20 minutes.

[0093] (d) Transfer the mol...

Embodiment 3

[0096] (a) Prepare a polyvinyl alcohol solution, under the condition of nitrogen protection, stir 20 parts of polyvinyl alcohol in 200 parts (by weight) of water at a temperature of 70-90°C to form a polyvinyl alcohol solution;

[0097] (b) Configure foaming solution: Take 100kg of polyvinyl alcohol solution configured in step (a), add it to the reaction kettle, heat to 40-50°C, control the stirring speed at 700-800 rpm, add foaming agent AC ( Azodicarbonamide) 0.5kg, stirred for 5-10 minutes, added 1kg of dispersant; stirred for 5-20 minutes;

[0098] (c) Acetal reaction, in the atmosphere of oxygen-poor air (air and nitrogen 1 / 1 volume mixing), control the stirring speed 700-1200 rpm, add 10kg of hydrochloric acid, stir for 10-20 minutes, add 12kg of formaldehyde, reduce Stir the speed to 400-500 rpm, stir for 10-30 minutes, add 0.3kg of foam stabilizer OP-10, and gradually reduce the stirring speed until the stirring stops, the process is about 5-20 minutes.

[0099] (d) T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com