Preparation method and application of super-hydrophobic nanofibers of coral structure

A nanofiber, superhydrophobic technology, applied in the chemical characteristics of fibers, textiles and papermaking, one-component synthetic polymer rayon, etc., can solve the inconvenience of production and life in mass production of superhydrophobic materials, difficult to prepare with superhydrophobic surfaces , reducing the surface energy and other issues, to achieve the effects of good superhydrophobicity, fast and simple preparation method, and low surface free energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

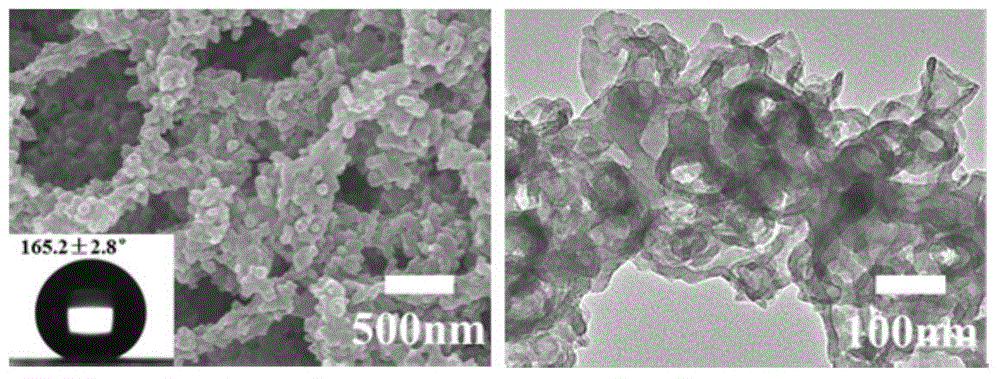

[0035] Dissolve 0.05g of sorbitan stearate (Span-60) in 125g of n-heptane, add 0.1g of boron trifluoride ethyl ether initiator dropwise, oscillate to emulsify it evenly, and adjust the temperature of the system to 20 ℃, add 2g of divinylbenzene (DVB) monomer, put into 20 ℃ constant temperature water bath to react for 30 minutes, and obtain dark red precipitate. Afterwards, the reaction was terminated with ethanol, and the white powder product was obtained by filtration. It is a superhydrophobic coral-structured nanofiber.

[0036] The scanning electron microscope and transmission electron microscope photos of the polymer nanofibers are as follows figure 1 shown. The length of the obtained polymer fiber material is more than 1 μm, and the diameter of the nanofiber is 10-500 nm. On the surface of the nanofiber, protrusions are uniformly distributed, the diameter of the protrusions is 1-200nm, and the length is 1-500nm.

[0037] The obtained material is prepared into a coatin...

Embodiment 2

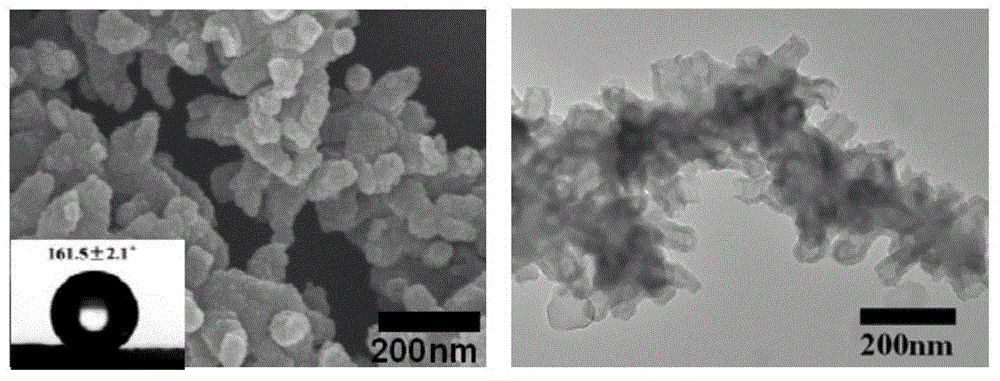

[0039] Dissolve 0.15g of sorbitan monostearate (Span-60) in 125g of n-hexane, add dropwise 0.1g of boron trifluoride ethyl ether initiator, oscillate to emulsify evenly, and adjust the temperature of the system to 25°C , add 2g of divinylbenzene (DVB) monomer, put into 25 ℃ constant temperature water bath to react for 20 minutes, obtain deep red cotton flocculent precipitate. Afterwards, the reaction was terminated with ethanol, and a white cotton floc product was obtained by filtration. The resulting superhydrophobic coral-structured nanofibers.

[0040] The scanning electron microscope and transmission electron microscope photos of the polymer nanofibers are as follows figure 2 shown. The length of the obtained polymer fiber material is more than 1 μm, and the diameter of the nanofiber is 10-500 nm. On the surface of the nanofiber, protrusions are uniformly distributed, the diameter of the protrusions is 1-200nm, and the length is 1-500nm.

[0041] The obtained nanofibers...

Embodiment 3

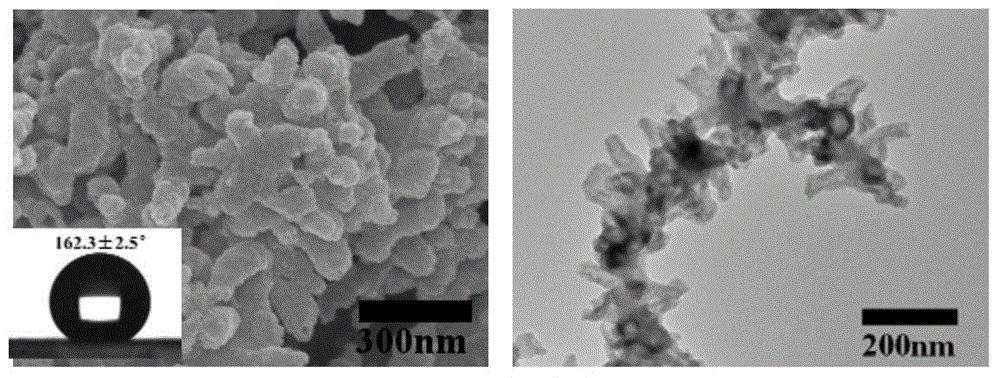

[0043] Dissolve 0.1g of sorbitan stearate (Span-60) in 125g of n-hexane solution, add dropwise 0.1g of boron trifluoride ethyl ether initiator, oscillate to emulsify evenly, and adjust the temperature of the system to 25°C , add 4g of divinylbenzene (DVB) monomer, put into 25 ℃ constant temperature water bath and react for 30 minutes, obtain dark red cotton flocculent precipitate. Afterwards, the reaction was terminated with ethanol, and a white cotton floc product was obtained by filtration. The resulting coral-structured nanofibrous material.

[0044] The scanning electron microscope and transmission electron microscope photos of the polymer nanofibers are as follows image 3 shown. The length of the obtained polymer fiber material is more than 1 μm, and the diameter of the nanofiber is 10-500 nm. On the surface of the nanofiber, protrusions are uniformly distributed, the diameter of the protrusions is 1-200nm, and the length is 1-500nm.

[0045] The obtained material is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com