a grafted sio 2 Preparation method of particle cluster orientation reinforced polyester fiber

A polyester fiber and particle technology, which is applied in the field of preparation of grafted SiO2 particle cluster orientation reinforced polyester fiber, can solve the problems of no reinforcing material, composite fiber without reinforcing fiber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~15

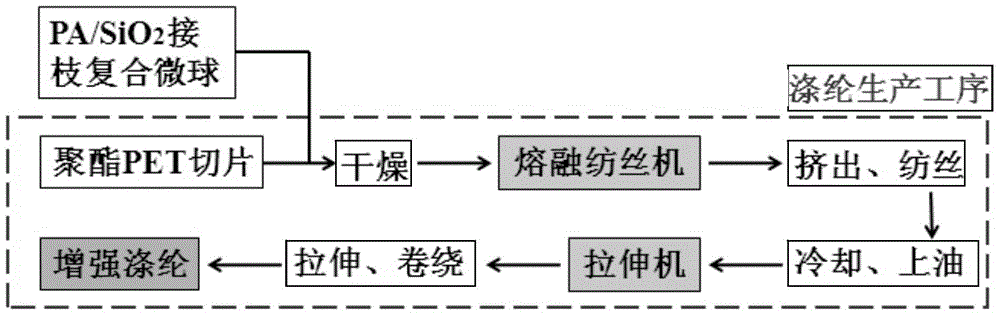

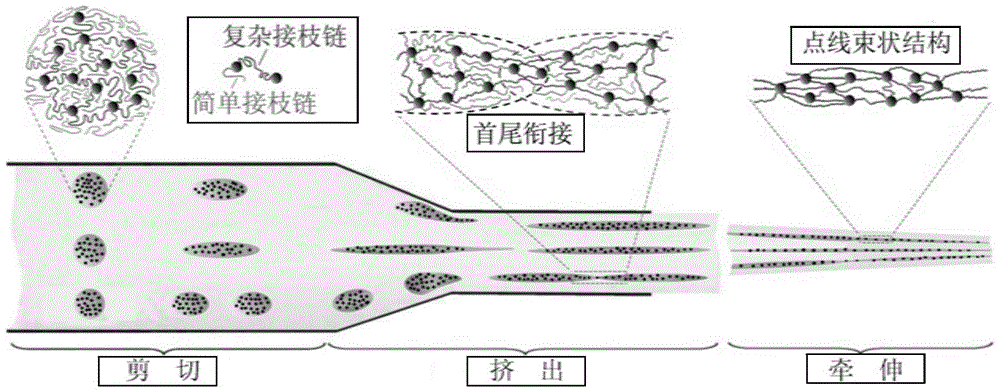

[0053] A kind of grafted SiO 2 The preparation method of particle cluster orientation reinforced polyester fiber includes:

[0054] 100g polyethylene terephthalate chips (PET semi-dull chips produced by Deli Chemical Fiber Co., Ltd., with an intrinsic viscosity of 0.678) were vacuum dried at 125°C for 8 hours to obtain dried polyethylene terephthalate Slice particles, control the water mass fraction at 2×10 -7 the following;

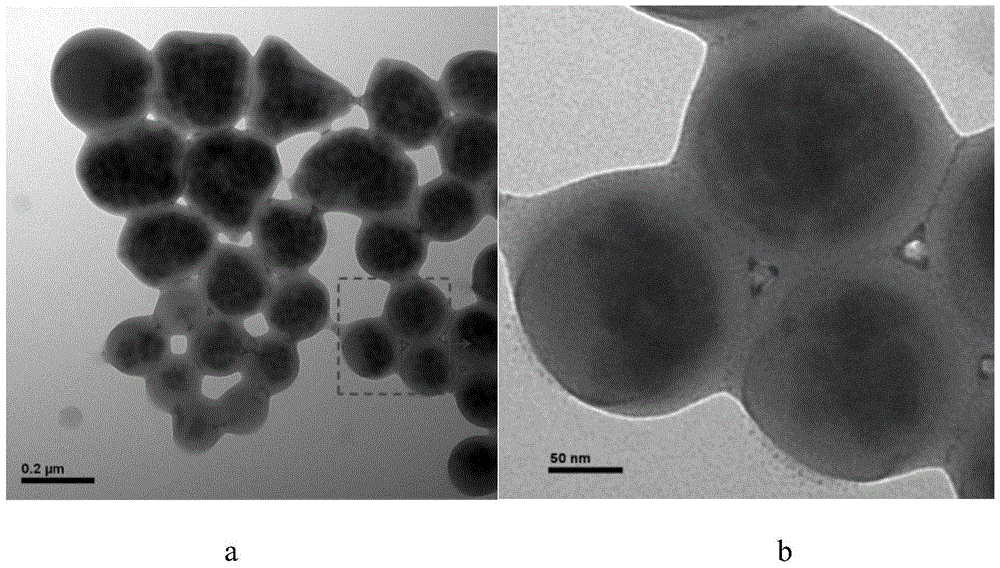

[0055] PMMA / SiO 2 Grafted composite microspheres (powder, Polymer, 2006, 47: 4622~4629, pomegranate-shaped, pomegranate-shaped microspheres consist of multiple nano-SiO 2 The particles are encapsulated in a polymethyl methacrylate latex particle, and they are interconnected by PMMA graft chains between the particles.) Dry under vacuum at 125°C for 8 hours to obtain dried PMMA / SiO 2 Grafted composite microspheres, control the water mass fraction at 2×10 -7 the following;

[0056] The dried polyethylene terephthalate chip pellets and dried PMMA / SiO 2 After the gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com