Silicon-based laser device and method for manufacturing same

A laser and silicon-based technology, applied in phonon exciters, electrical components, circuits, etc., can solve the problems of insufficient intensity, insufficient luminous efficiency, and difficult preparation methods, and achieve simple structure, enhanced light wave intensity, and preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

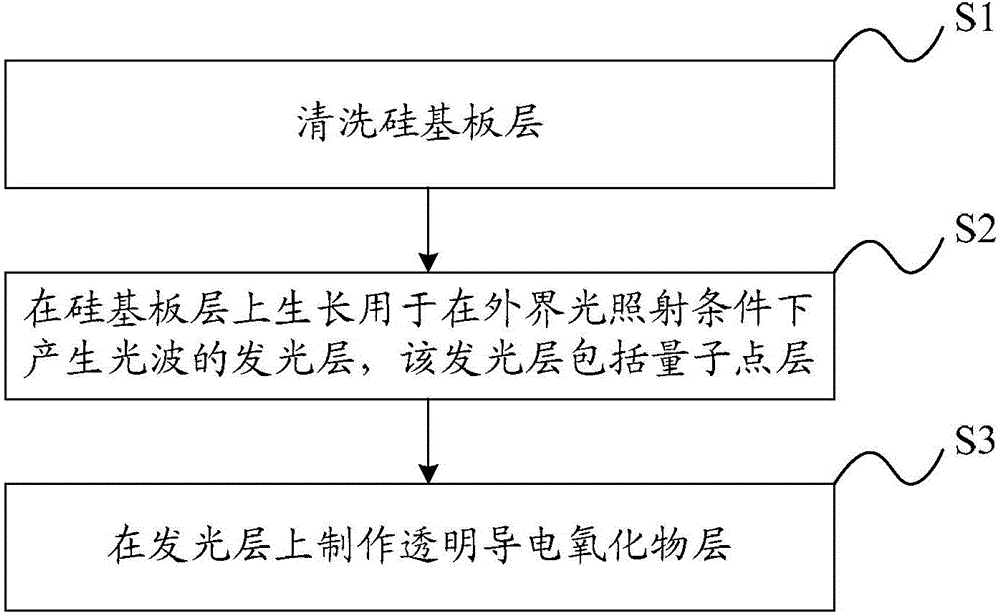

[0054] Correspondingly, as image 3 As shown, the present invention also provides a method for preparing a silicon-based laser, which can prepare any silicon-based laser provided by the embodiment of the present invention, and the preparation method includes:

[0055] S1, cleaning the silicon substrate layer;

[0056] S2. Growing a luminescent layer on the silicon substrate layer for generating light waves under the condition of external light irradiation, the luminescent layer includes a quantum dot layer;

[0057] S3. Fabricating a transparent conductive oxide layer on the light emitting layer.

[0058] The silicon-based laser manufacturing method provided by the embodiment of the present invention has simple process, low cost, and is easy to operate and realize.

[0059] Specifically, the fabrication of a transparent conductive oxide layer on the light-emitting layer in step S3 may specifically include:

[0060] Fabricate a discontinuous array made of transparent conduct...

Embodiment 1

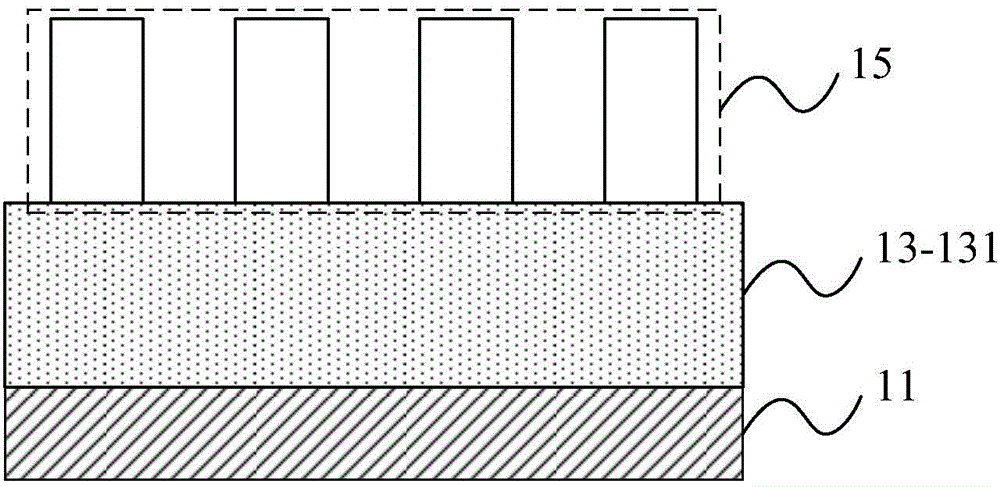

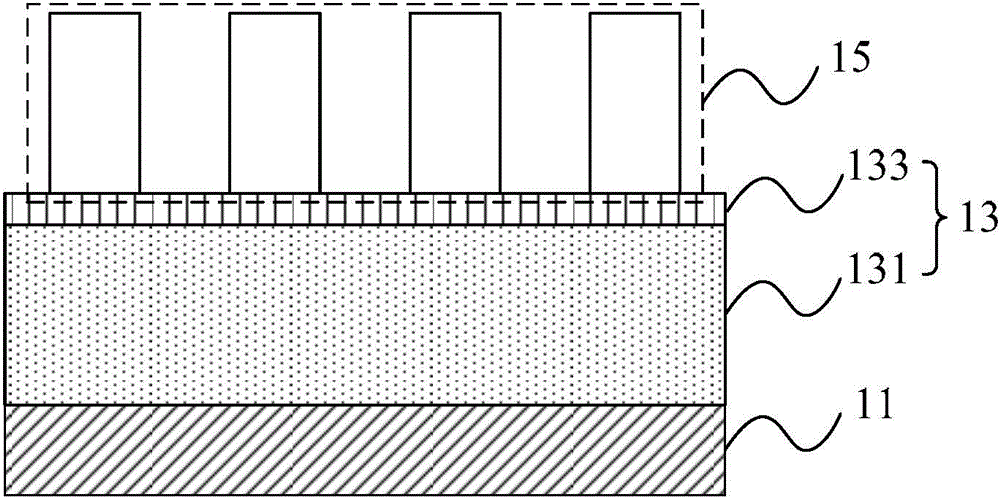

[0078] The silicon-based laser provided by the embodiment of the present invention includes a single-crystal silicon substrate, and a cylindrical periodic array of ten light-emitting layers and a layer of transparent conductive oxide are sequentially arranged on the single-crystal silicon substrate, wherein the light-emitting layer includes germanium quantum dots layer and a silicon protective layer positioned on the germanium quantum dot layer to prevent the quantum dot layer from being oxidized; specifically, the germanium quantum dots in the germanium quantum dot layer are all less than 50 nanometers in size, and the thickness of the protective layer is 15 nanometers , the cylinder periodic array parameters are 20 nm in height, 100 nm in diameter, and 400 nm in period.

[0079]When an external light source with a wavelength of 1550 nanometers is irradiated, the germanium quantum dots in the germanium quantum dot layer are excited to emit near-infrared light with a wavelength...

Embodiment 2

[0101] The difference from Embodiment 1 is that in Embodiment 1, the transparent conductive oxide is arranged as a periodic array of cylinders, while in the silicon-based laser provided by the embodiment of the present invention, the transparent conductive oxide is arranged as a periodic array of spheres, and the spheres are periodically The specific parameters of the array are: a diameter of 100 nanometers and a period of 400 nanometers.

[0102] Correspondingly, in the silicon-based laser preparation method of the embodiment of the present invention, the preparation steps of the transparent conductive oxide spherical periodic array are also different from the preparation steps of the transparent conductive oxide cylindrical periodic array provided in the first embodiment. The specific steps are:

[0103] Fabricating a periodic array of spherical transparent conductive oxides on the light-emitting layer is specifically: using a photoresist etching method to fabricate a period...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com