Flurbiprofen axetil fat emulsion concentrate and preparation method and use thereof

A flurbiprofen axetil and fat emulsion technology, applied in the field of flurbiprofen axetil fat emulsion concentrate, can solve the problems of unstable process, uneven milk particles, complicated preparation process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

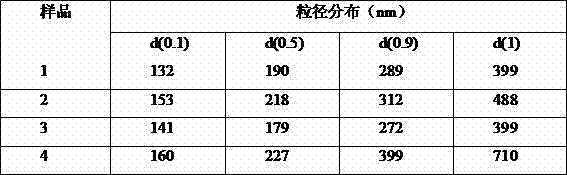

Examples

Embodiment 1

[0166] Embodiment 1: the preparation of flurbiprofen axetil fat emulsion concentrate sample 1

[0167] Its composition is as follows:

[0168] Flurbiprofen axetil 7g

[0169] soybean oil 5 grams

[0170] Medium chain fatty acid triglycerides (Crodamol GTCC) 60g

[0171] 1,2-Propanediol 8g

[0172] Soy lecithin (Epikuron 170, Degussa) 7.5 grams

[0173] Tween 80 4g

[0174] Polyethylene glycol lauryl hydroxystearate (Solutol HS 15, BASF) 8.2 g

[0175] Vitamin E 0.3g

[0176] The preparation method of the flurbiprofen axetil fat emulsion concentrate is as follows:

[0177] 1) Add the above-mentioned weight of soybean lecithin into medium-chain fatty acid glycerides and soybean oil at 20°C, and stir at 20,000 rpm until a transparent and clear solution is formed;

[0178]2) Add the above-mentioned weight of flurbiprofen axetil to the product of step 1) at 20°C, and keep stirring at 200rpm until the whole system is transparent;

[0179] 3) Add the above-mentioned we...

Embodiment 2

[0181] Embodiment 2: the preparation of flurbiprofen axetil fat emulsion concentrate sample 2

[0182] Its composition is as follows:

[0183] Flurbiprofen axetil 4.5g

[0184] soybean oil 29 grams

[0185] Glyceryl caprylate (Miglyol 812, SASOL) 29g

[0186] 1,2-Propanediol 7g

[0187] Soy Lecithin (Epikuron 170, Degussa) 11g

[0188] Polyglyceryl Oleate 4g

[0189] Polyethylene glycol lauryl hydroxystearate (Solutol HS 15, BASF) 11 g

[0190] Tween 80 4g

[0191] Vitamin E 0.3g

[0192] Oleic acid 0.2g

[0193] The preparation method of the flurbiprofen axetil fat emulsion concentrate is as follows:

[0194] 1) At 45°C, add the above-mentioned weight of soybean lecithin and polyglyceryl oleate into caprylic capric glyceride and soybean oil, and stir at 2000rpm until a transparent and clear solution is formed;

[0195] 2) Add the above-mentioned weight of flurbiprofen axetil to the product of step 1) at 35°C, and keep stirring at 1000rpm until the whole system is tr...

Embodiment 3

[0198] Embodiment 3: the preparation of flurbiprofen axetil fat emulsion concentrate sample 3

[0199] Its composition is as follows:

[0200] Flurbiprofen axetil 5.5g

[0201] 47.5 grams soybean oil

[0202] 1,2-propanediol 9 grams

[0203] Soy Lecithin (Epikuron 170, Degussa) 12g

[0204] Polyglyceryl Oleate 2.6g

[0205] Polyethylene glycol lauryl hydroxystearate (Solutol HS 15, BASF) 13 g

[0206] Tween 80 10g

[0207] Vitamin E 0.35g

[0208] Oleic acid 0.05g

[0209] The preparation method of the flurbiprofen axetil fat emulsion concentrate is as follows:

[0210] 1) At 30°C, add the above-mentioned weight of soybean lecithin and polyglycerol oleate into soybean oil, and stir at 10,000 rpm until a transparent and clear solution is formed;

[0211] 2) Add the above-mentioned weight of flurbiprofen axetil to the product of step 1) at 45°C, and keep stirring at 2000rpm until the whole system is transparent;

[0212] 3) At 45°C, add the above-mentioned weight of 1,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com