Preparation method for nonmetallic element-doped MxFe3-xO4@TiO2 magnetic composite material

A technology of mxfe3-xo4tio2 and magnetic composite materials, which is applied in the preparation of MxFe3-xO4TiO2 magnetic composite materials and the preparation of non-metallic element doped MxFe3-xO4TiO2 magnetic composite materials, which can solve the problem of weak stability and insufficient regeneration ability of composite materials to achieve excellent photocatalytic activity, improve recycling rate, and broaden the photoresponse range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

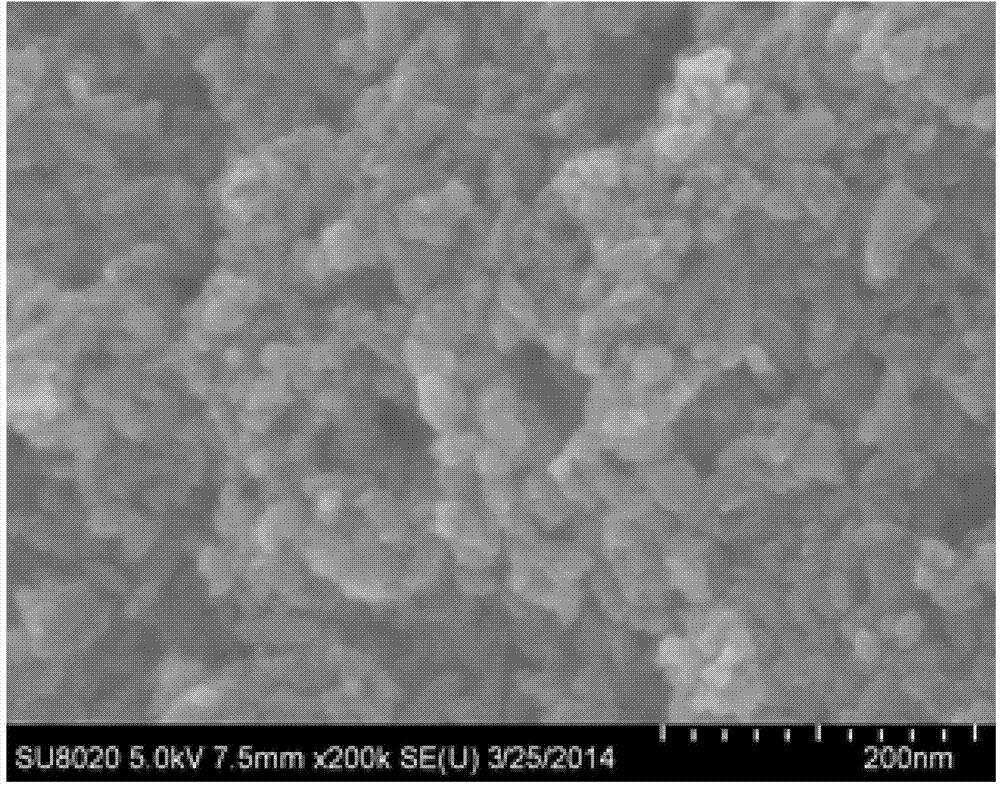

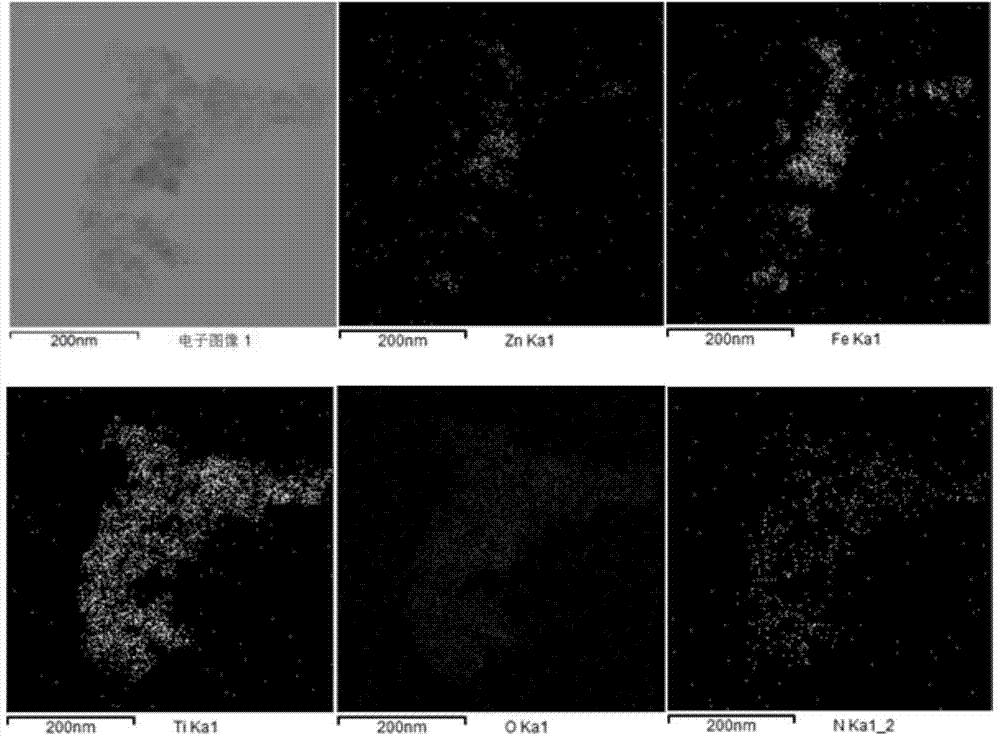

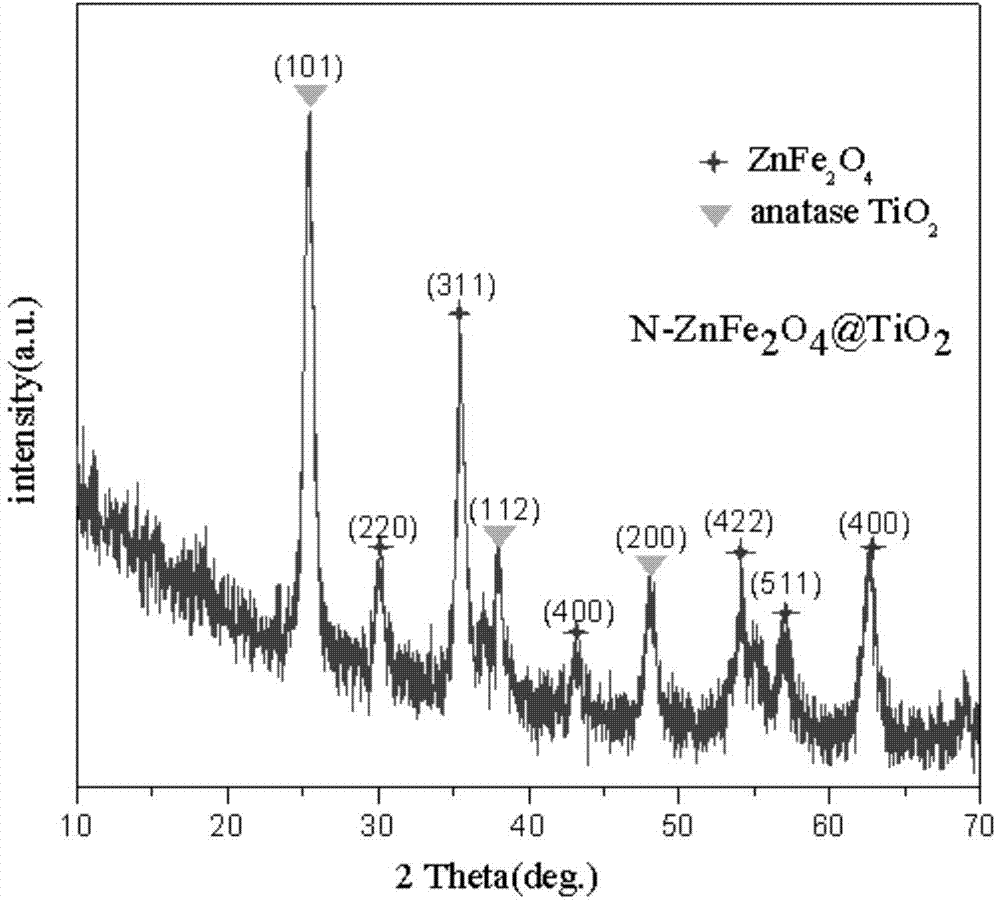

Image

Examples

Embodiment 1

[0024] (1) Weigh 10mmol Zn(CH 3 COO) 2 2H 2 O(AR) and 20mmol Fe(NO 3 ) 3 9H 2 Dissolve O(AR) in 100mL of ethanol (AR) solution with 2.5g of polyvinylpyrrolidone dissolved, magnetically stir and mix evenly, slowly add 30mL of aqueous solution dissolved with 0.5mol NaOH, adjust the pH, stir for 1h and mix evenly to obtain a mixed solution; Put the mixed solution into a double-chamber polytetrafluoroethylene-lined stainless steel reaction kettle, seal it under high pressure at 180°C for 20 hours, and then cool it naturally to room temperature; magnetically separate the reactants and wash them with ethanol for several times until they are neutral to obtain magnetic Zn x Fe 3-x o 4 nanoparticles.

[0025] (2) Weigh 0.5mmol magnetic Zn x Fe 3-x o 4 Nanoparticles were dispersed in 40mL ethanol dissolved with 0.05mmol urea, and ultrasonically treated for 10 hours; 10mL ethanol solution dissolved with 0.5mmol n-butyl titanate (AR) was slowly added dropwise to the turbid solut...

Embodiment 2

[0032] The preparation method of this embodiment is the same as that of Example 1, the difference is only: in the synthesis of magnetic Zn x Fe 3-x o 4 The surfactant used for nanoparticles is 2.5g polyvinyl alcohol, and the lye used is ammonia water / NH 4 HCO 3 In the aqueous solution, the titanium salt used is titanium tetrachloride, and the step (2) is to react in a stainless steel reactor at 200° C. for 10 hours to obtain the target product.

[0033] In the same manner as in Example 1, the photocatalytic oxidation performance of the composite material obtained in this example was tested, and the removal rate of Rhodamine B was 98%.

Embodiment 3

[0035] The preparation method of this embodiment is the same as that of Example 1, the only difference is that the water-soluble metal M 2+ Salt selection Co(CH 3 COO) 2 4H 2 O(AR), and Fe(NO 3 ) 3 9H 2 O(AR) was dissolved in ethanol and mixed evenly with magnetic stirring to prepare magnetic Co x Fe 3-x o 4 Nanoparticles, finally made N element doped Co x Fe 3-x o 4 TiO 2 magnetic composites.

[0036] In the same manner as in Example 1, the photocatalytic oxidation performance of the composite material obtained in this example was tested, and the removal rate of Rhodamine B was 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com