Novel soundproof polystyrene foam sheet and preparation method thereof

A polystyrene foam and board technology, applied in the field of building boards, can solve problems such as inapplicability, limited application range, and poor sound insulation performance, so as to achieve good barrier effect and improve sound insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

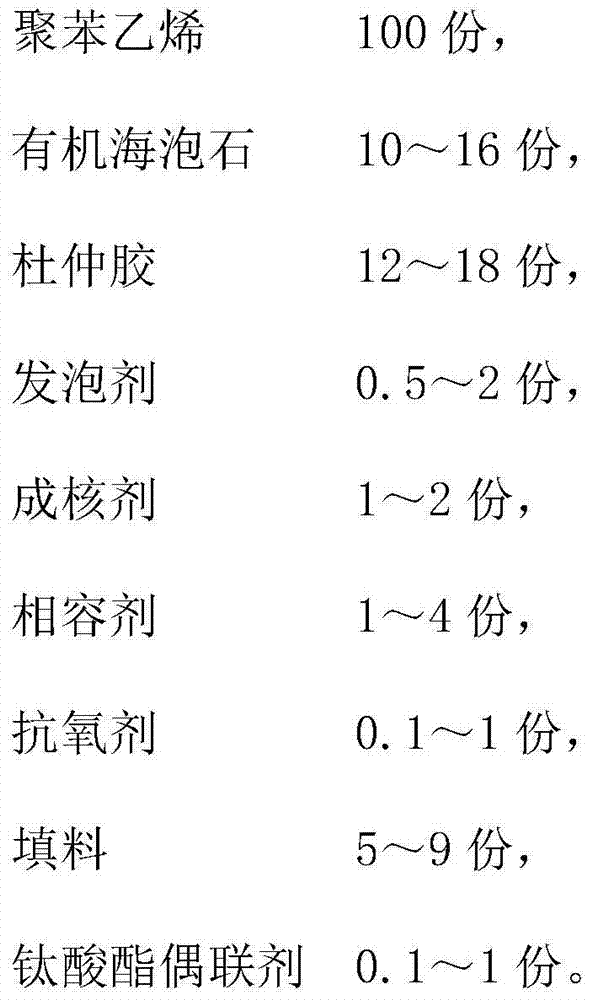

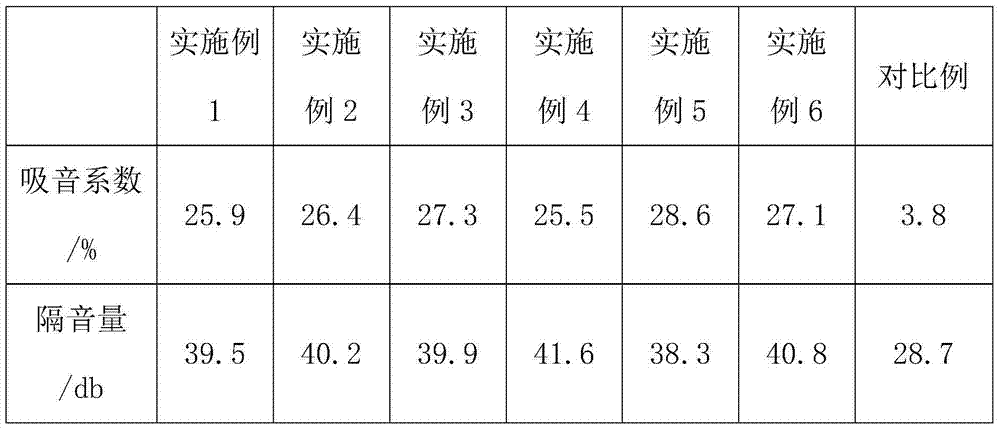

[0029] A sound-insulating polystyrene foam board, its parts by weight are composed of: 100 parts of polystyrene, 12 parts of organic sepiolite, 18 parts of Eucommia gum, 0.5 part of azodicarbonamide, 1.4 parts of talcum powder, styrene-mass 2 parts of toric anhydride copolymer, 0.1 part of phenolic antioxidant, 6 parts of calcium carbonate, 0.6 part of titanate coupling agent.

[0030] The steps of its preparation method are as follows:

[0031] (1) Pulverize sepiolite to obtain sepiolite powder, add sepiolite powder and hydrochloric acid solution with a concentration of 1.6mol / L together in a constant temperature water bath at 75°C and stir, the weight ratio of sepiolite powder to hydrochloric acid solution is 1:25, stop stirring after 5 hours, take it out, filter it, wash it with deionized water 3 times, put it in a drying oven at 110°C and dry it for 1 hour to obtain acidified sepiolite;

[0032] (2) Dissolving the silane coupling agent in the ethanol solution and mixing u...

Embodiment 2

[0037] A sound-insulating polystyrene foam board, which is composed of 100 parts by weight of polystyrene, 10 parts of organic sepiolite, 14 parts of Eucommia gum, 0.8 part of trichlorofluoromethane, 2 parts of talcum powder, styrene-malay 1 part of acid anhydride copolymer, 0.5 part of phenolic antioxidant, 7 parts of calcium carbonate, 0.5 part of titanate coupling agent.

[0038] The steps of its preparation method are as follows:

[0039] (1) Pulverize sepiolite to obtain sepiolite powder, add sepiolite powder and hydrochloric acid solution with a concentration of 1.6mol / L together in a constant temperature water bath at 75°C and stir, the weight ratio of sepiolite powder to hydrochloric acid solution is 1:25, stop stirring after 5 hours, take it out, filter it, wash it with deionized water 3 times, put it in a drying oven at 110°C and dry it for 1 hour to obtain acidified sepiolite;

[0040] (2) Dissolving the silane coupling agent in the ethanol solution and mixing unif...

Embodiment 3

[0045] A sound-insulating polystyrene foam board, which consists of 100 parts by weight of polystyrene, 14 parts of organic sepiolite, 15 parts of Eucommia gum, 2 parts of trichlorofluoromethane, 1.6 parts of talcum powder, styrene-malay 4 parts of anhydride copolymer, 0.2 part of phenolic antioxidant, 9 parts of zinc oxide, 0.1 part of titanate coupling agent.

[0046] The steps of its preparation method are as follows:

[0047] (1) Pulverize sepiolite to obtain sepiolite powder, add sepiolite powder and hydrochloric acid solution with a concentration of 1.6mol / L together in a constant temperature water bath at 75°C and stir, the weight ratio of sepiolite powder to hydrochloric acid solution is 1:25, stop stirring after 5 hours, take it out, filter it, wash it with deionized water 3 times, put it in a drying oven at 110°C and dry it for 1 hour to obtain acidified sepiolite;

[0048](2) Dissolving the silane coupling agent in the ethanol solution and mixing uniformly to prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com