Improved organic-inorganic hybrid solid having a modified outer surface

A solid, organic technology, applied in the field of preparation, can solve stability problems, biomedical application obstacles and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0440] Embodiment 1: Synthesis of nanoparticles of various MOFs

[0441] MIL-89 Nano Fe 3 OX[C 4 h 4 (CO 2 ) 2 ] 3 nH 2 O (X=F, Cl, OH)

[0442] From ferric acetate (1 mmol; synthesized according to the procedure described in C.T. Dziobkowski, T.J. Wrobleski, D.B. Brown, Inorg. Chem. 1982, 21, 671 [51]) and muconic acid (1 mmol; Fluka, 97%) in 5 mL of ethanol (Riedel-de 99.8%), with the addition of 0.25 mL of 2M sodium hydroxide (Alfa Aesar, 98%), MIL-89 nanometers were synthesized in an autoclave (Paar bomb) at 100° C. for 12 h. After cooling the vessel, the product was recovered by centrifugation at 5000 rpm for 10 minutes.

[0443] 200 mg of the solid was suspended in 100 mL of distilled water and stirred for 15 h to remove any solvent remaining in the pores. Then, the solid was recovered by centrifugation at 5000 rpm for 10 minutes.

[0444] The particle size measured by light scattering was 400 nm.

[0445] The nanoparticles show a round and slightly elongate...

Embodiment 2

[0480] Example 2: Synthesis of nanoparticles of iron trimesate MIL-100 functionalized with βCDP

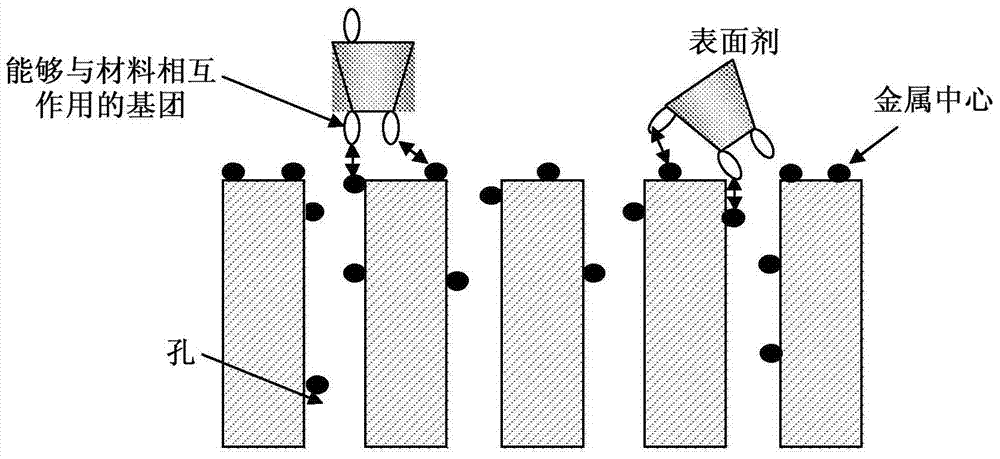

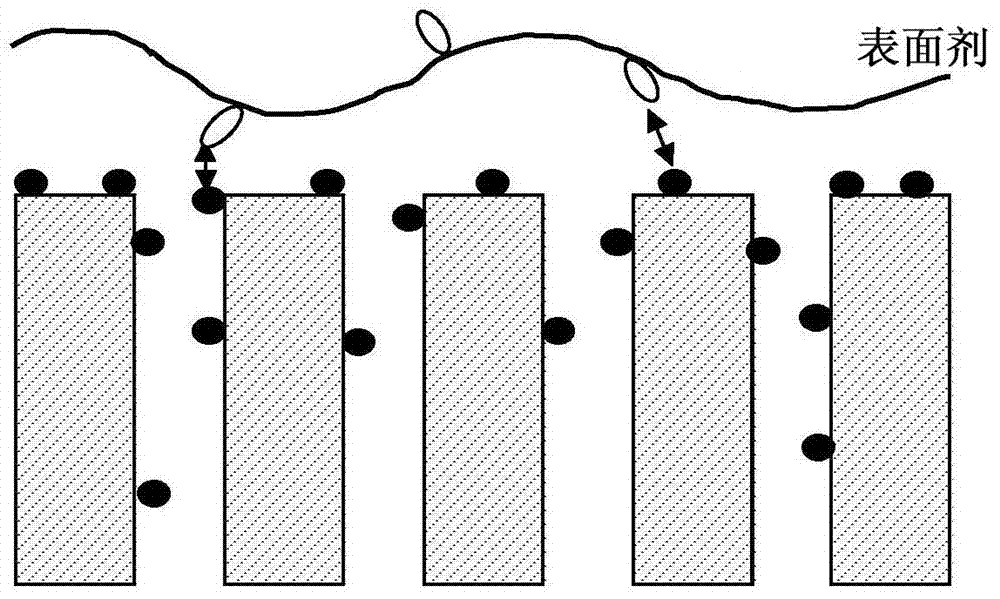

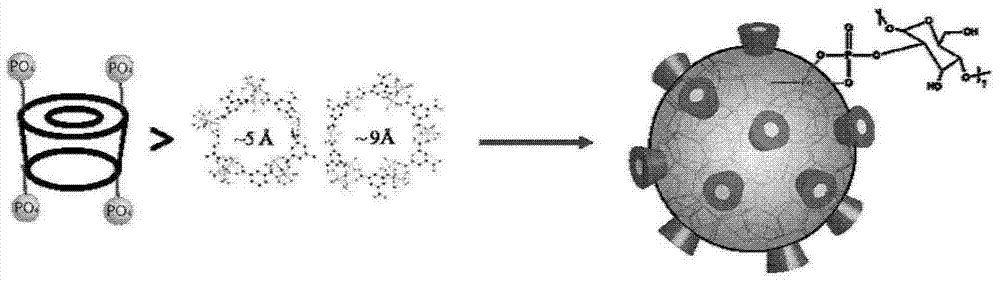

[0481] With β-cyclodextrin phosphate (βCDP, Cyclolab, CY-2017.1, molecular formula: C 42 h 70 o 47 P 4 Na 4 ) modified organic-inorganic hybrid nanoparticles (nano-MOF) based on iron trimesate (MIL-100). This molecule has two essential features for effective surface modification of nano-MOFs: 1) it has a bulkier structure than the micropore windows of MIL-100, which should prevent it from being adsorbed in the pores, Thereby maintaining the porosity of the nanoparticles; 2) it is substituted by 4 phosphate groups, which should ensure a stable interaction with the nanoparticles by forming ionic covalent bonds with the iron atoms on the particle surface ( figure 2 ).

[0482] 2 mg of MIL-100 was modified by incubating with 500 μl of 2 mg / ml βCDP in water (weight ratio, nanoparticle:βCDP=1:0.5) for 24 h under stirring at room temperature. After incubation, the modified nanop...

Embodiment 3

[0510] Embodiment 3: synthetic branched chain PEG

[0511] At room temperature, under two-dimensional stirring, with 2 mL of 0.5 mg / mL star PEG (amino-dPEG TM (4)-[dPEG TM (12)-OMe] 3 , C 99 h 197 N 5 o 47 , 2209.63 g / mol, Iris Biotech, Germany) was incubated with an aqueous solution of 30 mg of MIL 100 nanoparticles for 2 minutes. At the end of the incubation, nanoparticles were recovered by centrifugation at 5600 xg for 10 min, followed by two washes with water. PEG was determined in the recovered supernatant after the first centrifugation by a colorimetric method (see Baleaux [33]). Only 1 wt% of PEG remained in the supernatant, suggesting that almost all PEG (99 wt%) interacted with the nanoparticles.

[0512] The porosity of the dried nanoparticles was analyzed by nitrogen adsorption at 77K. BET specific surface area from 1400m 2 / g changes to 1225m 2 / g, therefore, indicates that star PEG also penetrates the pores, as does linear PEG (see below). Furthermor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com