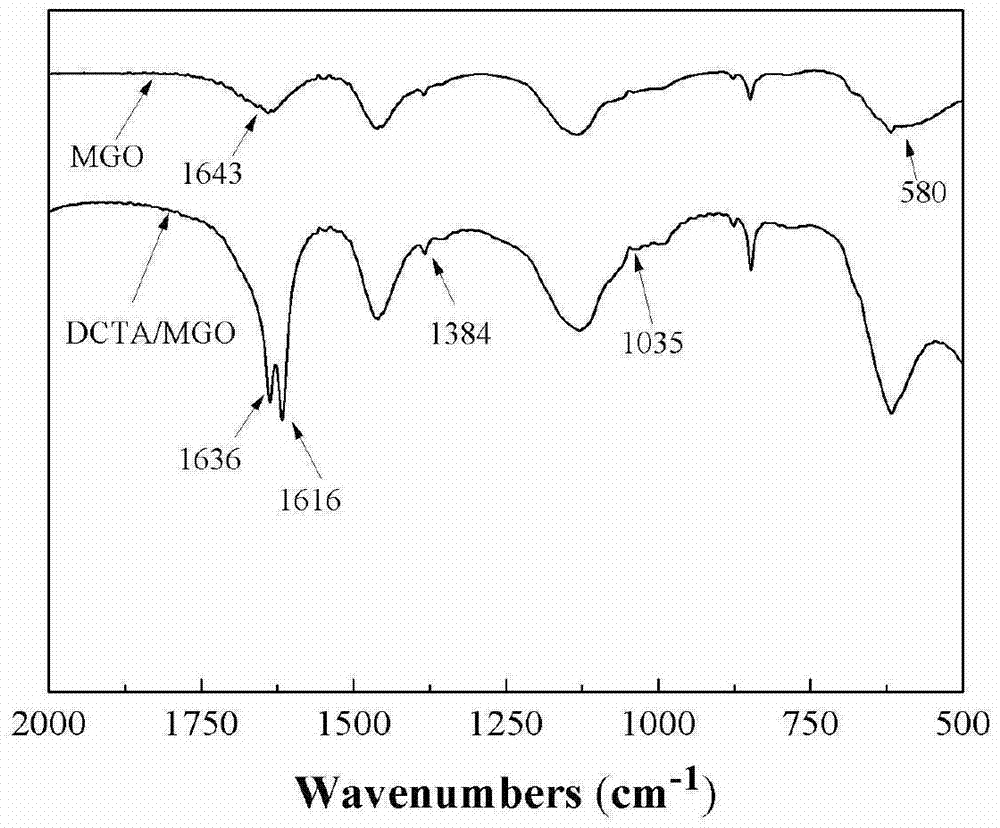

Method for removing hexavalent chromium in wastewater by using cyclohexane diamine-tetracetic acid modified magnetic graphene oxide

A technology of cyclohexamethylenediaminetetraacetic acid and oxidized rock, which is applied in chemical instruments and methods, other chemical processes, water/sewage treatment, etc., can solve the problems of reduced adsorption sites and decreased adsorption capacity, and achieve more adsorption sites , easy to operate, easy to separate and recycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

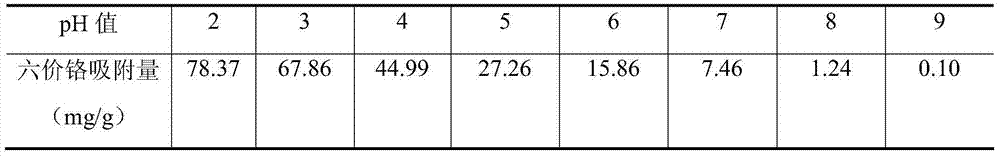

[0024] A method for removing hexavalent chromium in waste water by magnetic graphene oxide modified with cyclohexanediaminetetraacetic acid according to the present invention may further comprise the steps:

[0025] 1. Preparation of Adsorbent

[0026] (1) 3.0g graphite, 2.5g K 2 S 2 o 8 , 2.5g P 2 o 5 and 1~20mL H 2 SO 4 After mixing, heat it in a water bath to 60-100°C, add 0.5L of ultrapure water after 4 hours of reaction, let it stand for 12 hours after cooling, wash with ultrapure water to remove residual acid, dry it in vacuum at 60°C, and add the dried product to 120mL temperature H at 0°C 2 SO 4 (98%), then add 2.5g NaNO 3 , 15g KMnO 4 , and shake at 20°C for 4h, then react at 35°C for 2h, then add 250mL of water to ensure that the reaction temperature is controlled at 90°C, continue to shake for 1h, then add 0.5L of water and 20mL of H 2 o 2 (30%), shake at room temperature for 2h, then repeatedly wash with HCl (mass concentration is 10%) and water, then u...

Embodiment 2

[0037] A method for removing hexavalent chromium in waste water by magnetic graphene oxide modified with cyclohexanediaminetetraacetic acid according to the present invention may further comprise the steps:

[0038] 1. Preparation of Adsorbent

[0039] This step is the same as Step 1 of Example 1.

[0040] 2. Treatment of wastewater containing hexavalent chromium

[0041] Prepare 10 parts of 20mg / L hexavalent chromium solution, use 1mol / L NaOH or HNO 3 Adjust the pH to 3. Add the above-mentioned magnetic graphene oxide modified by cyclohexanediaminetetraacetic acid, and the amount of adsorbent is 0.066g / L. Place them in a constant temperature shaker at 30°C. The oscillator speed is 150 rpm, and the oscillation time is 10, 20, 30, 60, 90, 180, 360, 720, 1080, 1440 minutes respectively. After the reaction, place on a magnet to separate the adsorbent from the solution. The concentration of hexavalent chromium ions in the solution after adsorption was measured by ultraviolet...

Embodiment 3

[0047] A method for removing hexavalent chromium in waste water by magnetic graphene oxide modified with cyclohexanediaminetetraacetic acid according to the present invention may further comprise the steps:

[0048] 1. Preparation of Adsorbent

[0049] This step is the same as Step 1 of Example 1.

[0050] 2. Treatment of wastewater containing hexavalent chromium

[0051] Prepare hexavalent chromium solutions with concentrations of 10, 20, and 40mg / L respectively, and use 1mol / L NaOH or HNO 3 Adjust the pH to 3. Add the above-mentioned magnetic graphene oxide modified by cyclohexanediaminetetraacetic acid, and the amount of adsorbent is 0.066g / L. Place them in a constant temperature shaker at 30°C. The oscillator speed is 150 rpm, and the oscillation time is 24 hours respectively. After the reaction, place on a magnet to separate the adsorbent from the solution. The concentration of hexavalent chromium ions in the solution after adsorption was measured by ultraviolet spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com