Application of Citrobacter Citrobacter in the Preparation of Bioflocculants by Recycling Waste Algae

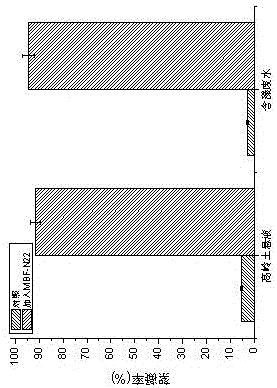

A technology of biological flocculant and Citrobacter, which is applied in the direction of flocculation/sedimentation water/sewage treatment, bacteria, seawater treatment, etc. It can solve the problems of limited scale algae control and high cost of biological flocculants, and achieve high-efficiency flocculation dosage, good Flocculation effect, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

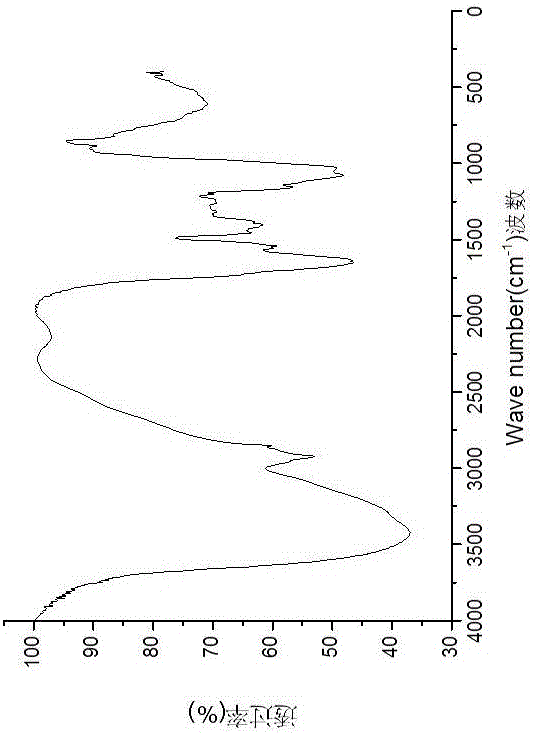

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of a bioflocculant of Citrobacter, comprising the following steps:

[0026] (a) Citrobacter is fermented and cultivated to obtain a fermented liquid, the medium of the fermented culture contains 1% glucose, the wet weight of algae cells is 5%, the rest is water, pH6.0; The weight is 0.5%, the culture temperature is 20°C, the shaking culture is 40 hours, the mycelium is removed by centrifugation, and the supernatant is obtained;

[0027] (b) Add 2 volumes of ethanol to the supernatant and store at 4°C for 12 hours. After the mixture is centrifuged, dissolve 3-5 g of the obtained precipitate in 100 ml of deionized water, and add 50 ml of 2% decachloride at the same time. Hexaalkylpyridine, shaken for 3 hours, after that, collect the precipitate and dissolve it in 100ml of 0.5M NaCl solution, add 2 times the volume of ethanol, centrifuge and collect the precipitate;

[0028] (c) The collected precipitate was eluted with ethanol, dissolved in 5ml of de...

Embodiment 2

[0034] Using the Citrobacter ( Citrobacter sp. AzoR-1 ) A method for preparing a bioflocculant, comprising the following steps:

[0035] (a) Citrobacter ( Citrobacter sp. AzoR-1 ) through fermentation to obtain a fermented liquid, wherein the culture medium of the fermentation contains 1.5% glucose, the wet weight of algae cells is 6.5%, the rest is water, pH7.0; the inoculum size is 1.2% based on the total weight of the fermentation medium, The culture temperature is 28°C, the shaking culture is carried out for 80 hours, and the mycelium is removed by centrifugation to obtain the supernatant;

[0036] (b) Add 2 times the volume of ethanol to the supernatant at 4°C for 12 hours. After the mixture is centrifuged, dissolve 4 g of the obtained precipitate in 100 ml of deionized water, and add 50 ml of 2% hexadecane chloride at the same time. Pyridine, shaken for 3.5 hours, after that, collect the precipitate and dissolve it in 100ml of 0.5M NaCl solution, add 2 times the volume...

Embodiment 3

[0043] Using the Citrobacter ( Citrobacter sp. AzoR-1 ) The method for preparing biological flocculant, is characterized in that, comprises the following steps:

[0044] (a) Citrobacter ( Citrobacter sp. AzoR-1 ) to obtain a fermented liquid through fermented culture, the culture medium of said fermented culture contains glucose 2%, the wet weight of algal cells is 8%, the rest is water, pH8.0; the inoculum size is 2% by the total weight of the fermented medium, The culture temperature is 35°C, the shaking culture is carried out for 120 hours, and the mycelium is removed by centrifugation to obtain the supernatant;

[0045] (b) Add 2 volumes of ethanol to the supernatant at 4°C for 12 hours, centrifuge the mixture, dissolve 5 g of the obtained precipitate in 100 ml of deionized water, and add 50 ml of 2% hexadecane chloride at the same time Pyridine, shaken for 4 hours, after that, collect the precipitate and dissolve it in 100ml of 0.5M NaCl solution, add 2 times the volume o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com