Preparation method of maleopimaric double-component waterborne polyurethane

A technology of maleopimaric acid and water-based polyurethane, applied in the field of coatings, can solve the problems of high viscosity of polyester, high reaction temperature, serious steric effect, etc., achieve the effects of green environmental protection cost, increase drying time, and improve comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

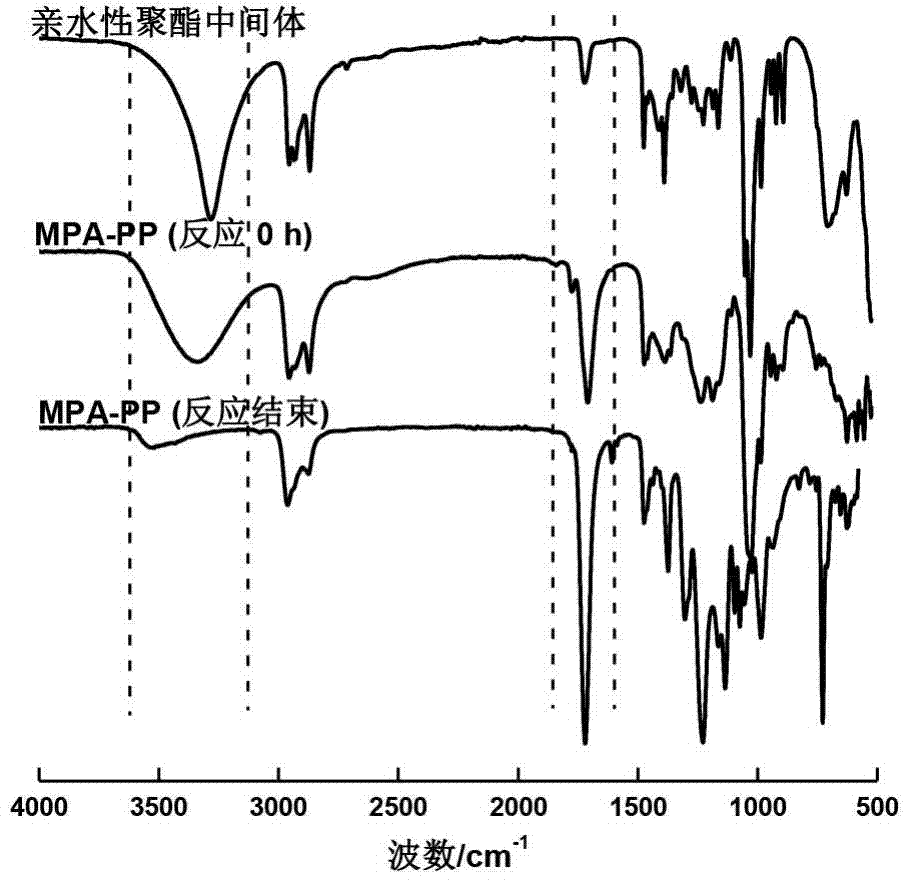

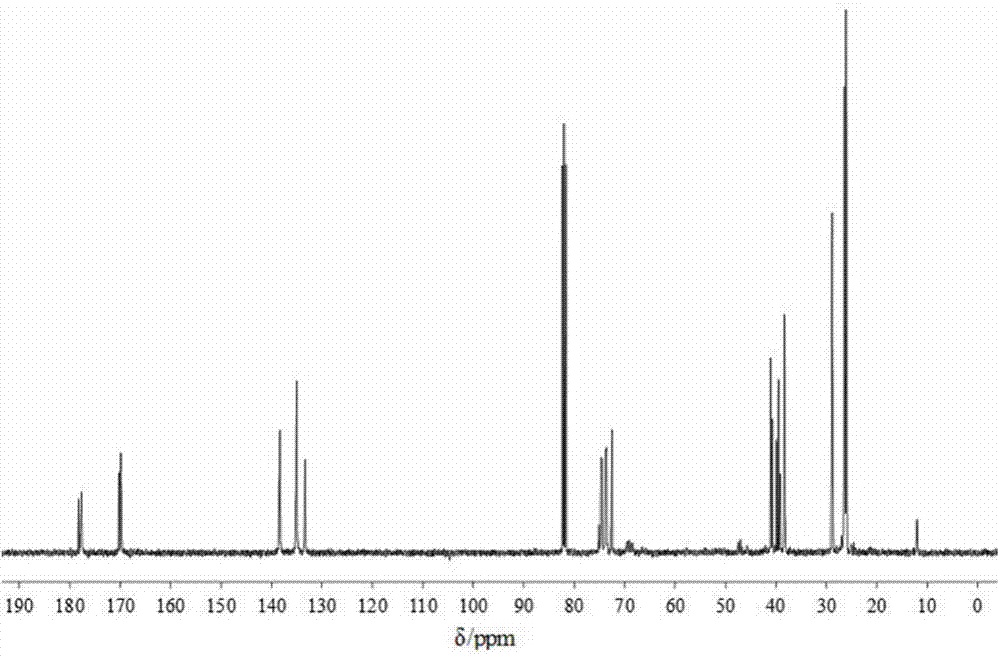

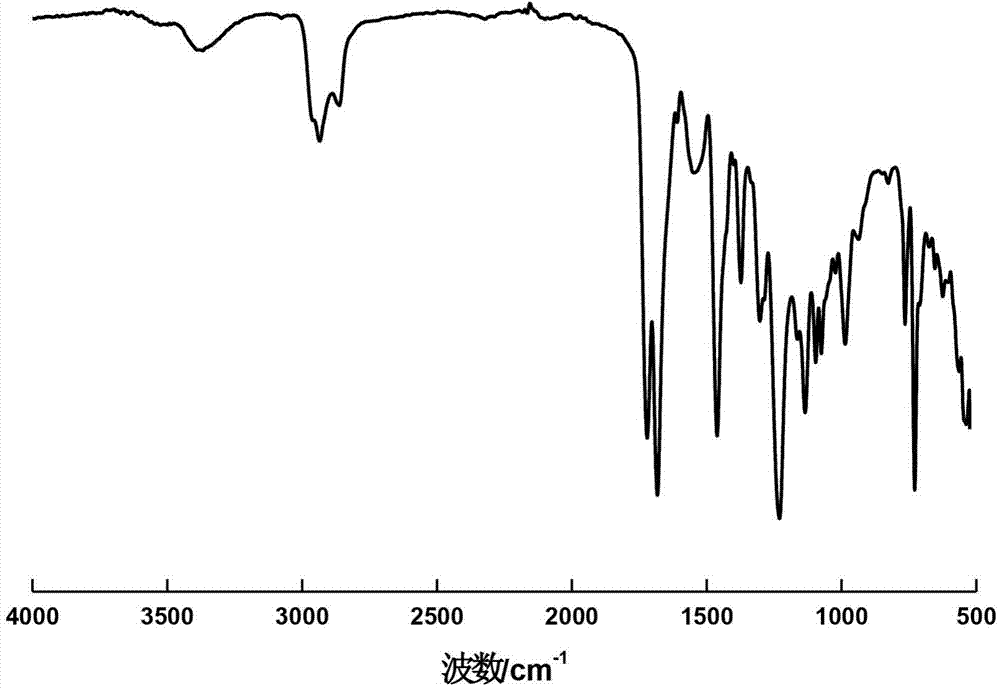

[0031] 40 parts of neopentyl glycol, 2.5 parts of isophthalic acid-5-sodium sulfonate, and 0.1 part of monohydroxybutyltin oxide were added to the reaction vessel, under N 2 Under protection, the temperature was raised to 190° C. at a rate of 1° C. / min, and kept for 50 minutes to obtain a hydrophilic polyester intermediate (HPI). When the above reaction system was cooled to 150°C, 9.2 parts of maleopimaric acid, 40 parts of isophthalic acid, 30 parts of adipic acid, and 10 parts of trimethylolpropane were added, and the temperature was raised to 210 at a rate of 0.5°C / min. ℃, keep warm for 70min, then add 7 parts of xylene to the reaction system, reflux reaction at 210℃ for 160min, when the temperature drops to 150℃, start to raise the temperature to 190℃ at a heating rate of 4℃ / min, and depressurize at the same time Vacuumize to produce maleopimaric acid polyester polyol (MPP). At 60°C, add mass sum to 80 parts of diethylene glycol monoethyl ether acetate and water (the mass...

Embodiment 2

[0035] 55 parts of neopentyl glycol, 4 parts of isophthalic acid-5-sodium sulfonate, and 0.25 parts of monohydroxybutyltin oxide were added to the reaction vessel, under N 2 Under protection, the temperature was raised to 210° C. at a rate of 1° C. / min, and kept for 20 minutes to obtain a hydrophilic polyester intermediate (HPI). When the above reaction system was cooled to 150°C, 43 parts of maleopimaric acid, 25 parts of isophthalic acid, 20 parts of adipic acid, and 7 parts of trimethylolpropane were added, and the temperature was raised to 240 at a rate of 0.5°C / min. ℃, keep warm for 40min, then add 5.5 parts of xylene to the reaction system, reflux reaction at 240℃ for 130min, when the temperature drops to 140℃, start to raise the temperature to 190℃ at a rate of 4℃ / min, and decompress while heating Vacuumize, cool down and discharge, and make maleopimaric acid polyester polyol (MPP). At 90°C, add mass sum to 110 parts of diethylene glycol monoethyl ether acetate and wat...

Embodiment 3

[0039] 45 parts of neopentyl glycol, 3 parts of isophthalic acid-5-sodium sulfonate, and 0.15 parts of monohydroxybutyltin oxide were added to the reaction vessel, under N 2 Under protection, the temperature was raised to 200° C. at a rate of 1° C. / min, and kept for 35 minutes to obtain a hydrophilic polyester intermediate (HPI). When the above reaction system was cooled to 150°C, 19 parts of maleopimaric acid, 35 parts of isophthalic acid, 25 parts of adipic acid, and 9 parts of trimethylolpropane were added, and the temperature was raised to 220 at a rate of 0.5°C / min. ℃, keep warm for 60min, then add 6 parts of xylene to the reaction system, reflux reaction at 220℃ for 150min, when the temperature drops to 150℃, start to raise the temperature to 190℃ at a heating rate of 4℃ / min, and depressurize at the same time Vacuumize, cool down and discharge, and make maleopimaric acid polyester polyol (MPP). At 70°C, add mass sum to 90 parts of diethylene glycol monoethyl ether aceta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com