Lipophilic polyurethane sponge and preparation method thereof

A polyurethane sponge, lipophilic technology, applied in chemical instruments and methods, other chemical processes, general water supply saving and other directions, can solve the problems of high cost, human health hazards, threats to the survival of marine organisms, etc., to achieve an increase in oil absorption rate and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

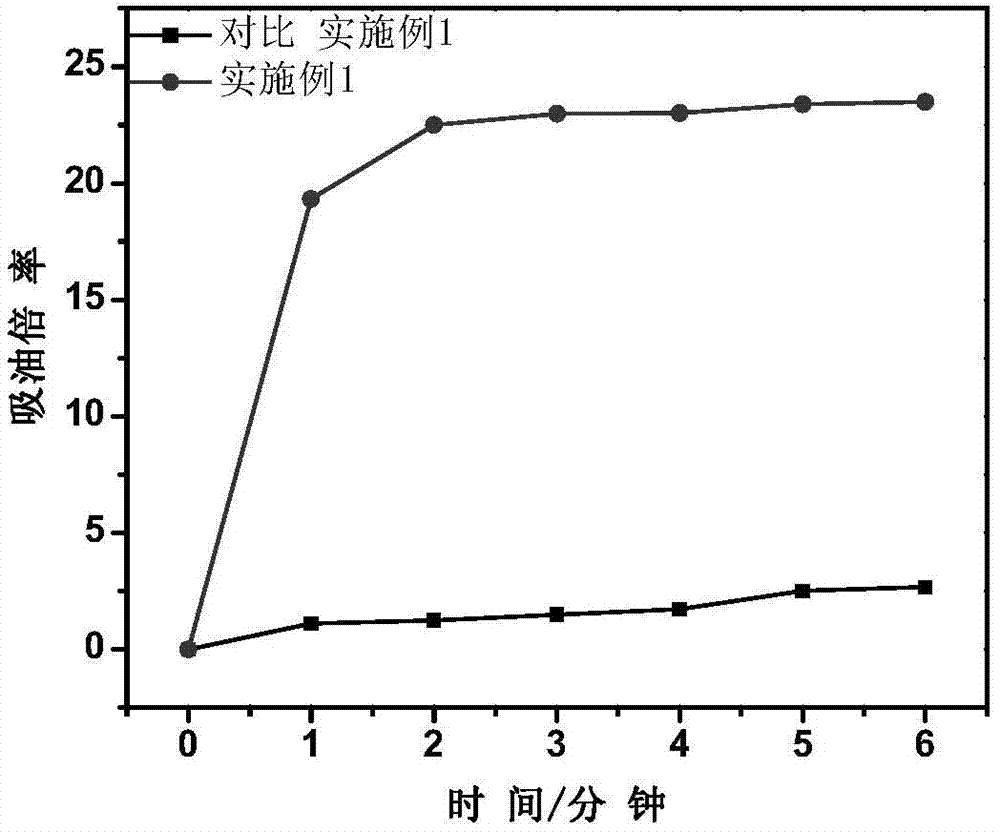

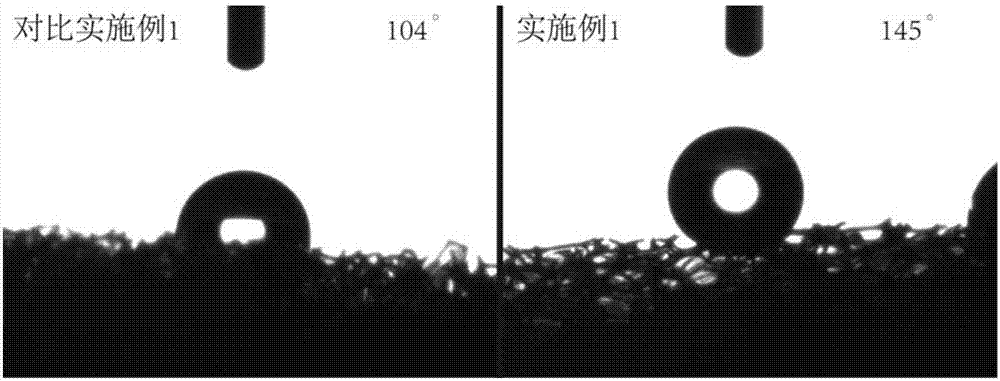

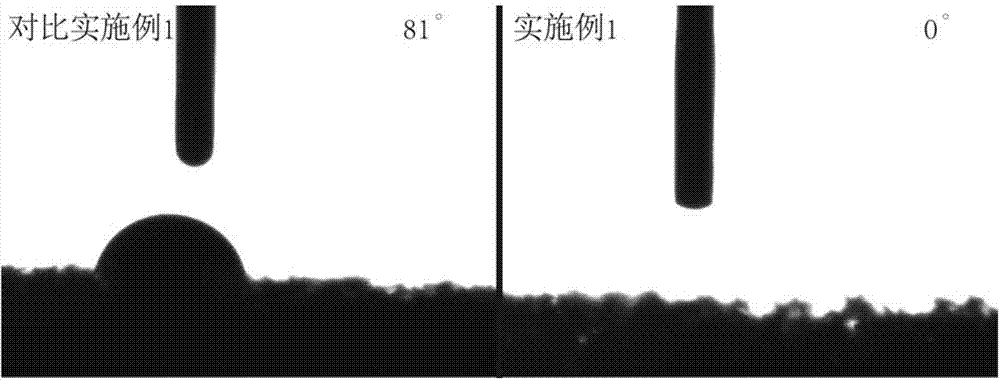

Embodiment 1

[0044] In this embodiment, a lipophilic polyurethane sponge is used, wherein the sponge substrate is exactly the same as the sponge selected in Comparative Example 1, and is a porous polyurethane sponge with an average pore diameter of 300 μm, and the substrate is grafted with lipophilic Hydrophobic C-C long chain group. The C-C long chain is polyurethane and the acid chloride compound CH containing C-C long chain 3 (CH 2 ) 16 COCl reaction, the amino, hydroxyl and -C(O)Cl functional groups in polyurethane are grafted through chemical bonds.

[0045] The preparation method of above-mentioned lipophilic polyurethane sponge is as follows:

[0046] (1) exactly the same as step (1) in comparative example 1;

[0047] (2) Measure 100ml of anhydrous dioxane into a 250ml beaker, and weigh 150mg of NaHCO 3 into the beaker, and then add 3ml of acid chloride CH 3 (CH 2 ) 16 COCl, after mixing uniformly, an acid chloride solution is obtained;

[0048] (3) Soak the sponge treated ...

Embodiment 2

[0054] The structure of the lipophilic polyurethane sponge used in this example is basically the same as that in Example 1, except that the sponge base is a polyurethane sponge with an average pore diameter of 600 μm.

[0055] The preparation method of the above-mentioned lipophilic polyurethane sponge is basically the same as the preparation method of the lipophilic polyurethane sponge in Example 1, the difference is that the sponge matrix uses a polyurethane sponge with an average pore diameter of 600 μm.

[0056] The above-mentioned lipophilic polyurethane sponge made is carried out the oil-absorbing performance test, and the test method is exactly the same as the method in Comparative Example 1, and the results are as follows:

[0057] After 3 minutes, the polyurethane sponge was completely submerged in crude oil, and the polyurethane sponge was weighed to obtain: the oil absorption of the polyurethane sponge was 45.9g / g, and the polyurethane sponge was centrifuged at a spe...

Embodiment 3

[0060] The structure of the lipophilic polyurethane sponge used in this example is basically the same as that in Example 1, except that the sponge base is a polyurethane sponge with an average pore diameter of 900 μm.

[0061] The preparation method of the above-mentioned lipophilic polyurethane sponge is basically the same as the preparation method of the lipophilic polyurethane sponge in Example 1, the difference is that the sponge matrix uses a polyurethane sponge with an average pore diameter of 900 μm.

[0062] The above-mentioned lipophilic polyurethane sponge made is carried out the oil-absorbing performance test, and the test method is exactly the same as the method in Comparative Example 1, and the results are as follows:

[0063] The above-mentioned lipophilic polyurethane sponge made is carried out the oil-absorbing performance test, and the test method is exactly the same as the method in Comparative Example 1, and the results are as follows:

[0064] After 1 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Oil absorption | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com