Building insulation coating and its preparing method

A technology for thermal insulation and construction, applied in coatings and other directions, can solve the problems of limited thermal insulation and thermal insulation effect, weak impact resistance, large drying shrinkage, etc., and achieve excellent thermal insulation performance, good drying performance, excellent The effect of thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

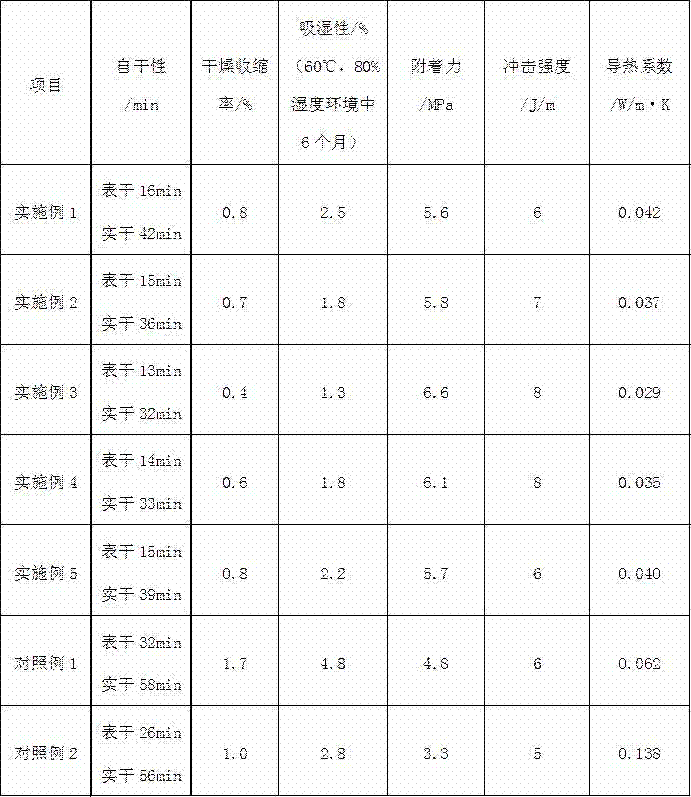

Examples

Embodiment 1

[0021] The preparation method of above-mentioned thermal insulation paint for building, comprises the following steps:

[0022] Step 1, diatomaceous earth, bentonite, hydroxypropyl methylcellulose, N-oleoyl sarcosine stearylamine and silicon dioxide are added to 100 parts of water by weight, heated to 60°C, and stirred for 20 minutes, Then heat to 80°C, stir for 15 minutes, then dry the mixed solution at 100°C to obtain a solid, crush the solid to a particle size of 100-200 μm, and the stirring speed above is 120 rpm minute;

[0023] Step 2, ethylene carbonate, ethyl 2-cyanoacrylate and ethyl acetate are added to the reflux device, the solid obtained in step 1 is added, heated and stirred to reflux for 40 minutes, the reflux stirring speed is 60 rpm, and the At room temperature, the mixture was obtained;

[0024] Step 3, add triethylene glycol monoethyl ether to the mixture obtained in step 2, stir at room temperature for 10 minutes at a stirring speed of 80 rpm, then add li...

Embodiment 2

[0027] The preparation method of above-mentioned thermal insulation paint for building, comprises the following steps:

[0028] Step 1, diatomaceous earth, bentonite, hydroxypropyl methylcellulose, N-oleoyl sarcosine stearylamine and silicon dioxide were added to 130 parts of water by weight, heated to 63°C, and stirred for 25 minutes, Then heat to 82°C, stir for 16 minutes, then dry the mixture at 105°C to obtain a solid, crush the solid to a particle size of 100-200 μm, and the stirring speed above is 130 rpm minute;

[0029] Step 2, ethylene carbonate, ethyl 2-cyanoacrylate and ethyl acetate are added to the reflux device, the solid obtained in step 1 is added, heated and stirred to reflux for 46 minutes, and the reflux stirring speed is 65 rpm, down to At room temperature, the mixture was obtained;

[0030] Step 3, add triethylene glycol monoethyl ether to the mixture obtained in step 2, stir at room temperature for 14 minutes at a stirring speed of 86 rpm, then add ligh...

Embodiment 3

[0033] The preparation method of above-mentioned thermal insulation paint for building, comprises the following steps:

[0034] Step 1, diatomaceous earth, bentonite, hydroxypropyl methylcellulose, N-oleoyl sarcosine stearylamine and silicon dioxide are added to 170 parts of water by weight, heated to 66°C, and stirred for 30 minutes, Then heat to 85°C, stir for 18 minutes, then dry the mixed solution at 110°C to obtain a solid, crush the solid to a particle size of 100-200 μm, and the stirring speed above is 140 rpm minute;

[0035] Step 2, ethylene carbonate, ethyl 2-cyanoacrylate and ethyl acetate are added to the reflux device, the solid obtained in step 1 is added, heated and stirred to reflux for 50 minutes, and the reflux stirring speed is 65 rpm, down to At room temperature, the mixture was obtained;

[0036] Step 3, add triethylene glycol monoethyl ether to the mixture obtained in step 2, stir at room temperature for 18 minutes, and the stirring speed is 90 rpm, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com