Organic thin-film solar cell based on dual mixed active layers and preparation method thereof

A technology of solar cells and organic thin films, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems that the FF of solar cells is not particularly high and the transmission is not enough, so as to increase the absorption range, improve the utilization efficiency, and improve the transmission efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

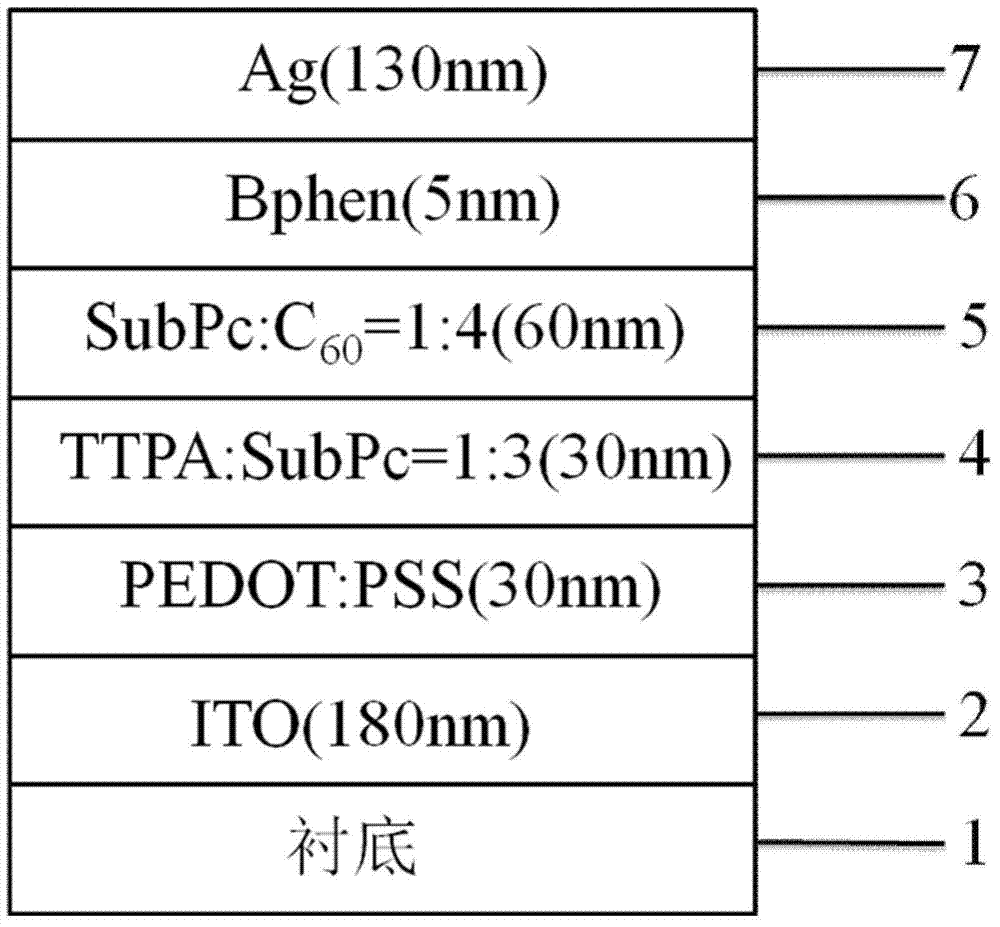

[0044] Device structure such as figure 1 shown. The material, thickness and doping ratio of each layer of the device are: the transparent substrate is glass, the transparent anode electrode is ITO, the thickness is 180nm; the anode modification layer is PEDOT:PSS, the thickness is 30nm; the mixed active layer is TTPA, the thickness is 30nm; mixed active layer 2 is SubPc:C60=1:4, with a thickness of 60nm; the electron buffer layer is Bphen, with a thickness of 5nm; the cathode electrode is Ag, with a thickness of 130nm.

[0045] Its preparation method is as follows:

[0046] ① Sputter the glass substrate of transparent anode electrode ITO with detergent, acetone solution, deionized water and ethanol solution for super

[0047] Acoustic cleaning, blow dry with dry nitrogen after cleaning;

[0048] ② Move the above-mentioned transparent anode ITO substrate into a vacuum chamber, and perform plasma treatment on the transparent anode ITO glass for 5 minutes under the pressure of...

Embodiment 2

[0055] Device structure such as figure 1 shown. The material, thickness and doping ratio of each layer of the device are: the transparent substrate is glass, the transparent anode electrode is ITO, and the thickness is 180nm; the anode modification layer is PEDOT:PSS, and the thickness is 30nm; the mixed active layer one is TTPA:SubPc= 3:1, the thickness is 30nm; the mixed active layer 2 is SubPc:C60=1:4, the thickness is 60nm; the electronic buffer layer is Bphen, the thickness is 5nm; the cathode electrode is Ag, the thickness is 130nm.

[0056] The preparation process is basically similar to that of Example 1, except that when the mixed active layer 1 is evaporated, the evaporation rate of TTPA is 3 times that of SubPc.

Embodiment 3

[0058] Device structure such as figure 1 shown. The material, thickness and doping ratio of each layer of the device are: the transparent substrate is glass, the transparent anode electrode is ITO, the thickness is 180nm; the anode modification layer is PEDOT:PSS, the thickness is 30nm; the mixed active layer 1 is TTPA:SubPc =1:1, the thickness is 30nm; the mixed active layer 2 is SubPc:C60=1:4, the thickness is 60nm; the electronic buffer layer is Bphen, the thickness is 5nm; the cathode electrode is Ag, the thickness is 130nm.

[0059] The preparation process is basically similar to that of Example 1, except that when evaporating the mixed active layer 1, the evaporation rate of TTPA is the same as that of SubPc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com