Method for preparing platinum nanowires through helicoverpa armigera nuclear polyhedron extractives

A nuclear polyhedron and protein extract technology, applied in the field of nanomaterial preparation, can solve the problems of high equipment requirements, environmental hazards, harsh preparation conditions, etc., and achieve the effect of uniform shape, stable structure and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] After every 20 mg of polyhedrosis virus was purified, the precipitate was dissolved in 1 mL of ultrapure water to obtain a polyhedron suspension. Take 10mL polyhedron suspension and add 500μL alkaline hydrolysis solution, which is a mixed solution of 0.3mol / L sodium carbonate, 0.5mol / L sodium chloride and 0.03mol / L disodium ethylenediaminetetraacetic acid solution, let stand 30min. Then add 5 mL of chloroform and shake evenly, take the supernatant after centrifugation, adjust the pH value to 6 with NaOH solution, put the supernatant into an ultracentrifuge tube after standing in a refrigerator at 4 °C for 12 hours, discard the supernatant after ultracentrifugation, The precipitated spots were dissolved with ultrapure water to obtain polyhedrin extract, and the obtained extract was freeze-dried at minus 105 degrees.

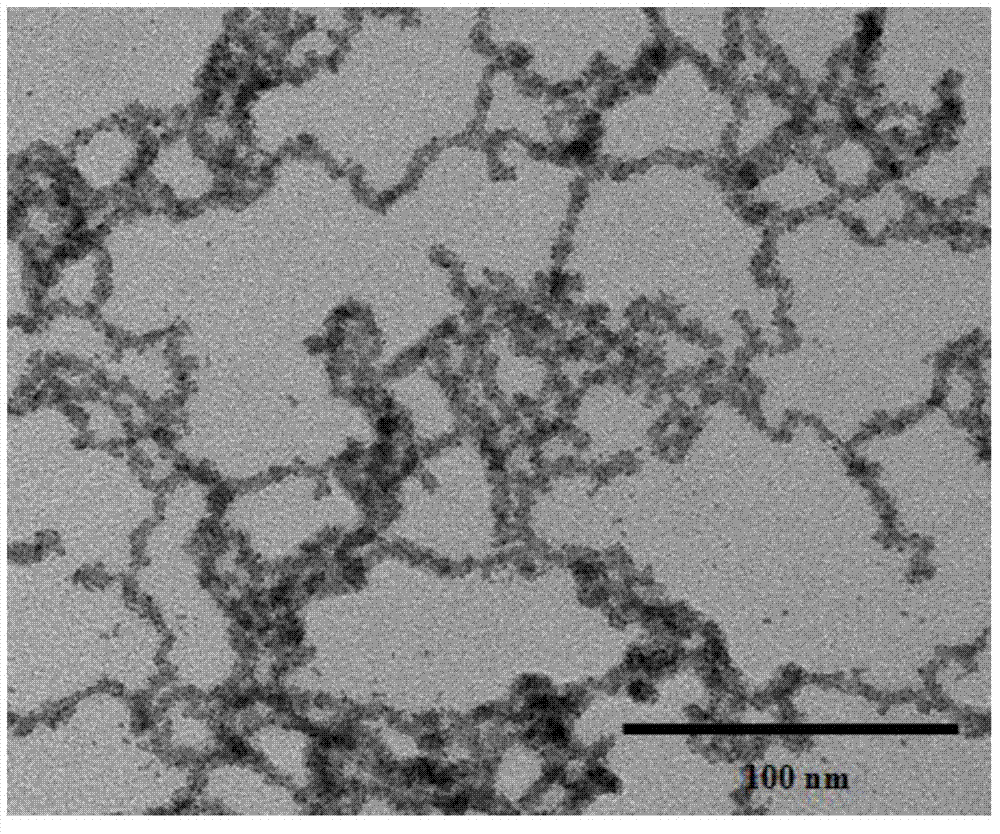

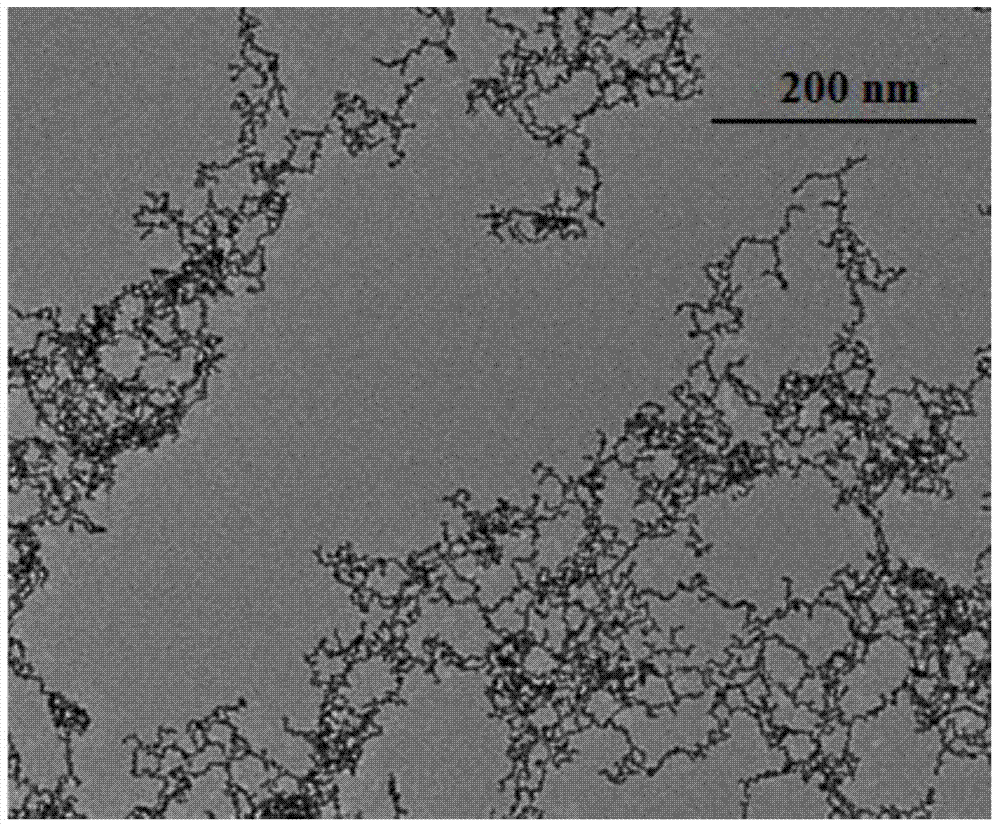

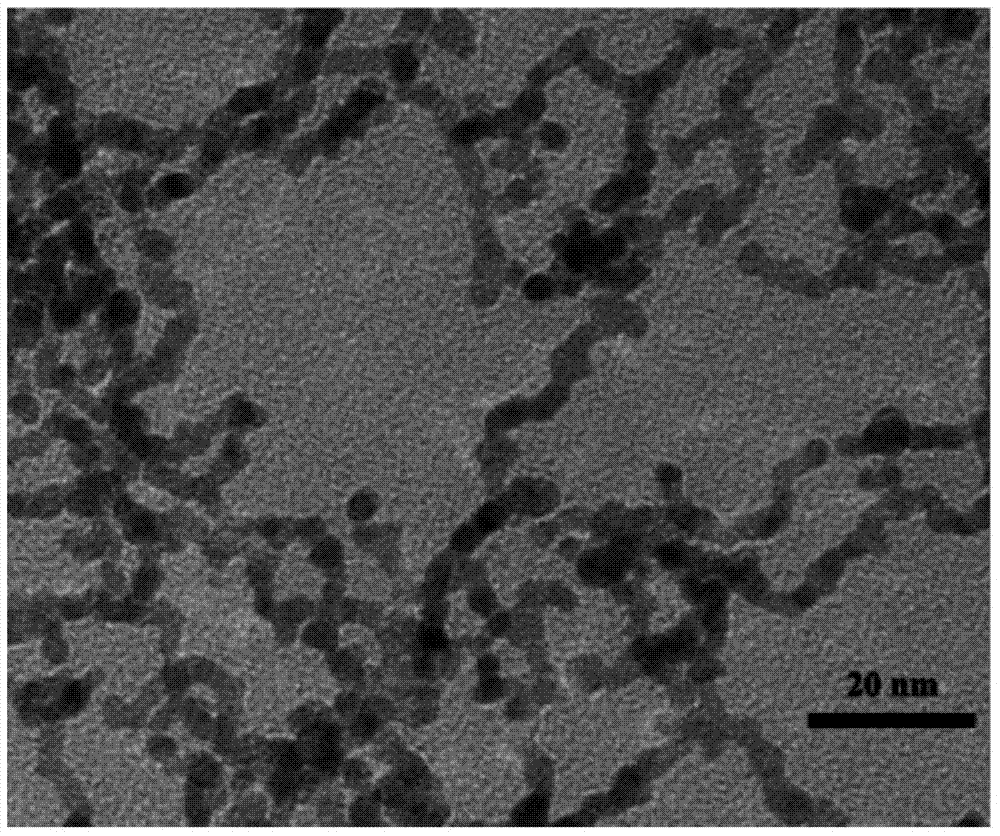

[0018] Weigh the freeze-dried powder of polyhedrin protein extract to prepare 10 μg / mL extract solution, take 800 μL protein extract solution, add 200 μL ...

Embodiment 2

[0020] After every 20 mg of polyhedrosis virus was purified, the precipitate was dissolved in 1 mL of ultrapure water to obtain a polyhedron suspension. Take 10mL polyhedron suspension and add 200μL alkaline hydrolysis solution, which is a mixture of 0.3mol / L sodium carbonate, 0.5mol / L sodium chloride and 0.03mol / L disodium ethylenediaminetetraacetic acid solution, let stand 60min. Then add 4 mL of chloroform and shake evenly, take the supernatant after centrifugation, adjust the pH value to 7 with NaOH solution, put the supernatant into an ultracentrifuge tube after standing in a refrigerator at 4 °C for 24 hours, discard the supernatant after ultracentrifugation, The precipitated spots were dissolved with ultrapure water to obtain polyhedrin extract, and the obtained extract was freeze-dried at minus 105 degrees.

[0021] Weigh the freeze-dried polyhedron protein extract to prepare a 30 μg / mL extract solution, take 1 mL of the protein extract solution, add 200 μL of K solut...

Embodiment 3

[0024] After every 20 mg of polyhedrosis virus was purified, the precipitate was dissolved in 1 mL of ultrapure water to obtain a polyhedron suspension. Take 10mL polyhedron suspension and add 400μL alkaline hydrolysis solution, which is a mixed solution of 0.3mol / L sodium carbonate, 0.5mol / L sodium chloride and 0.03mol / L disodium ethylenediaminetetraacetic acid solution, let stand 90min. Then add 2.5mL chloroform and shake evenly, take the supernatant after centrifugation, adjust the pH value to 6.5 with NaOH solution, put the supernatant into an ultracentrifuge tube after standing in a refrigerator at 4°C for 18 hours, discard the supernatant after ultracentrifugation , using ultrapure water to dissolve the precipitated spots to obtain the polyhedrin protein extract, and freeze-dry the obtained extract at minus 105 degrees.

[0025] Weigh the freeze-dried powder of polyhedrin protein extract to prepare 40 μg / mL extract solution, take 1200 μL protein extract solution, add 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com