Synthesis method of polyester polyol

A technology of polyester polyol and synthesis device, which is applied in the synthesis field of polyester polyol, can solve the problems of high COD of small molecular polyol, loss of small molecular polyol, slow reaction speed of materials, etc. The effect of short time and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

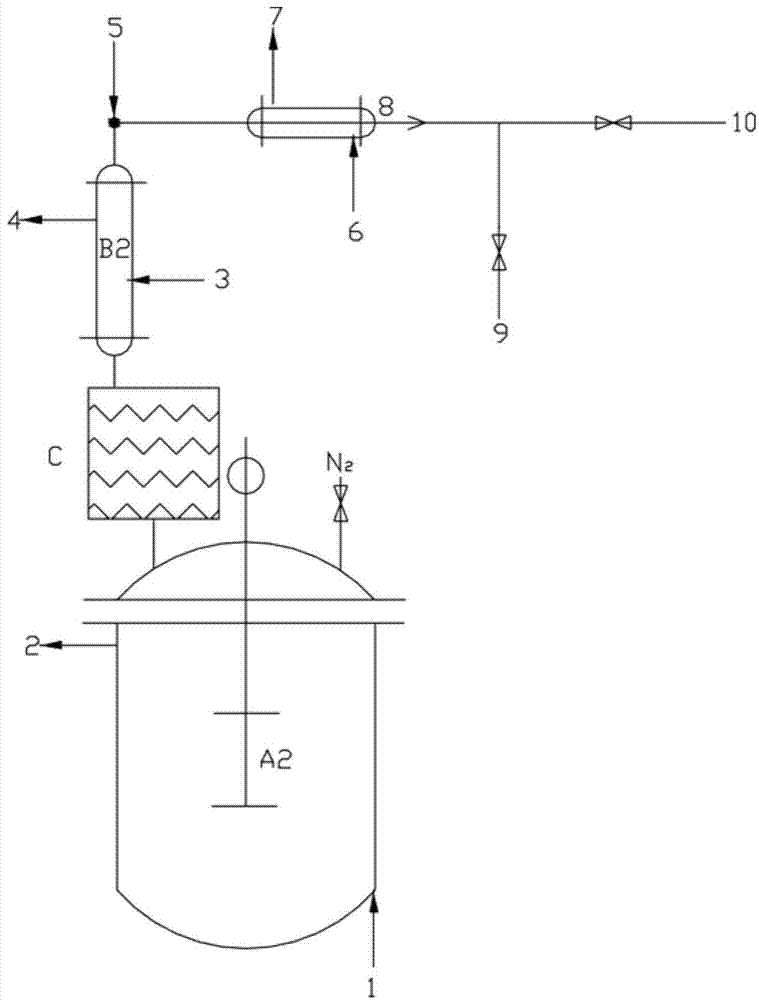

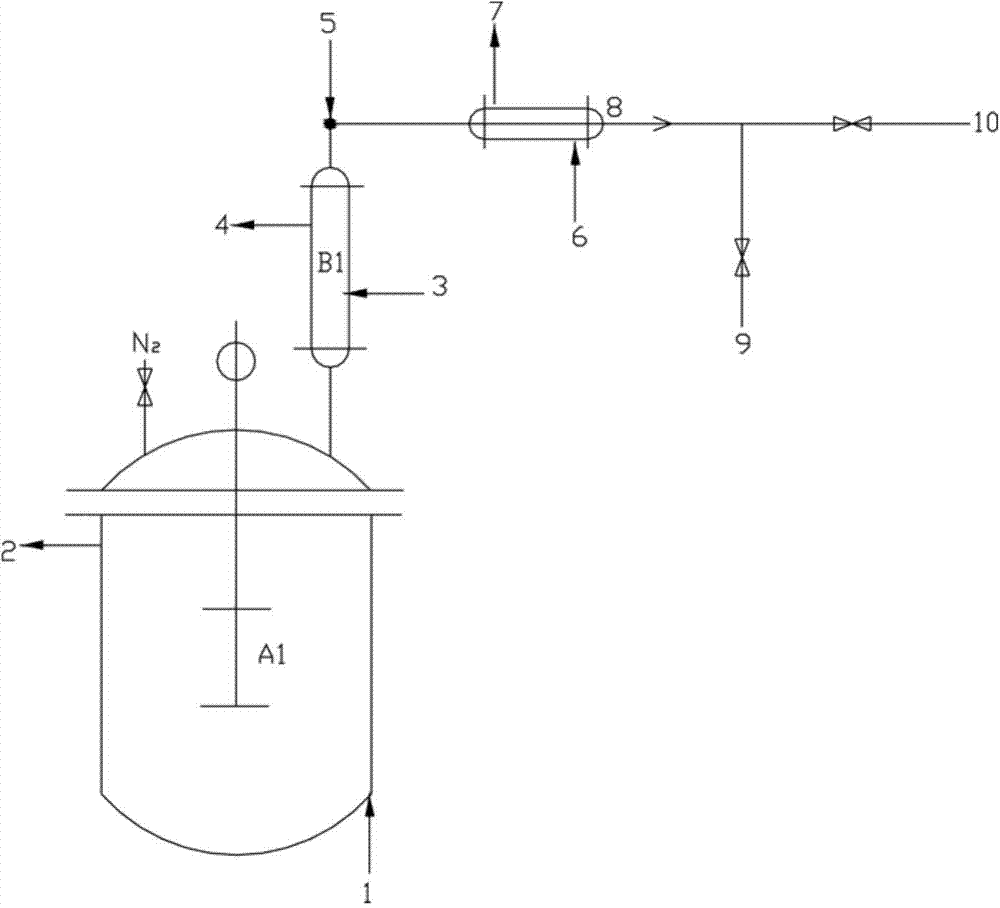

[0045] The production device of this embodiment is as simple as figure 1 As shown, the stainless steel jacketed reactor A2 has a volume of 6000L, the 2 square meter shell and tube stainless steel reflux condenser B2, the 4000L stainless steel intermediate tank C, and the intermediate tank C is equipped with 4000kg Molecular sieve, W-4 reciprocating vacuum system (including water collection tank), 260 degree hot oil, nitrogen.

[0046]Put 3212kg of adipic acid and 1488kg of ethylene glycol into the reaction kettle, heat up, the temperature of the material rises to 100°C, start stirring, turn on the cooling water of the reflux condenser B2, control the top temperature of the reflux condenser B2 to 90°C, and when the temperature of the material rises to 210 ℃, the top temperature of the reflux condenser B2 is turned off and the cooling water drops to 60℃, and the vacuum is turned on. Before turning on the vacuum, the cooling water of the reflux condenser B2 should be turned on ...

Embodiment 2

[0049] In the reaction device of embodiment 1, drop into 2628kg adipic acid, 2120kg diethylene glycol, heat up, material temperature rises to 100 ℃ and stir, open reflux condenser B2 cooling water, control reflux condenser B2 top temperature 90 ℃, when When the temperature of the material rises to 210°C, turn off the cooling water in the reflux condenser B2 and turn on the vacuum when the top temperature drops to 60°C. Before turning on the vacuum, turn on the cooling water of the reflux condenser B2 again, and control the top temperature of the reflux condenser B2 to 65°C. The vacuum degree of the system starts from -0.02MPa, and the vacuum degree increases every half an hour, in order of -0.04MPa, -0.06MPa, -0.08MPa, -0.095MPa. Then react under vacuum for another 4.5 hours. Sampling, acid value 1.85mgKOH / g.

[0050] The total reaction time is about 16 hours. The molecular weight of polyester polyol is 2040.

Embodiment 3

[0052] In the reaction device of embodiment 1, drop into 3182.8kg adipic acid, 1339.2kg ethylene glycol, 198kg trimethylolpropane, heat up, the material temperature rises to 100 ℃ and start stirring, open reflux condenser B2 cooling water, control reflux condensation The top temperature of the condenser B2 is 90°C. When the material temperature rises to 210°C, turn off the cooling water in the reflux condenser B2 and the top temperature drops to 60°C, and turn on the vacuum. Before turning on the vacuum, turn on the cooling water of the reflux condenser B2 again to control the reflux condensation The top temperature of vessel B2 is 65°C, the vacuum degree of the reaction system starts from -0.02MPa, and the vacuum degree increases every half an hour, in order of -0.04MPa, -0.06MPa, -0.08MPa, -0.095MPa. Then react under vacuum for another 4.5 hours. Sampling, acid value 1.81mgKOH / g.

[0053] The total reaction time is about 16 hours. The molecular weight of polyester polyol i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com