A kind of continuous refining method of glycidyl tertiary carbonic acid ester

A glycidyl ester and refining method technology, applied in the direction of organic chemistry, can solve the problems of high equipment cost, long separation process time, non-continuous production, etc., and achieve the goal of overcoming low product purity, long production cycle, and reducing equipment cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

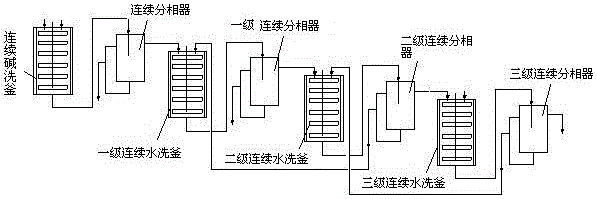

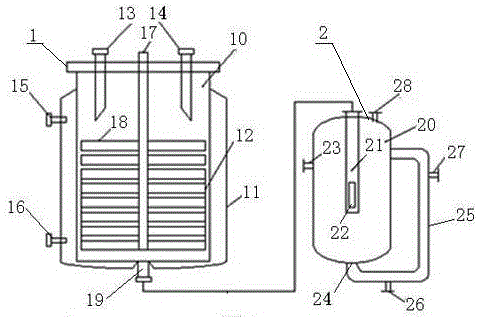

[0049] A method for refining glycidyl tertiary carbonic acid ester, the method adopts the above-mentioned continuous alkali cleaning device for glycidyl tertiary carbonic acid ester, the specific steps are: in a jacketed 1L continuous alkaline washing kettle, continuously add impurities Content is 5.4% crude glycidyl ester of tertiary carbonic acid (Pt / Co chromaticity 60), rate is 3.5L / h, continuously adds sodium hydroxide aqueous solution (sodium hydroxide weight percent is 50%), rate is 0.35L / h ,Such as figure 1 As shown, enter the continuous phase separator from the first discharge port at the lower end of the continuous alkali cleaning kettle, and the glycidyl tertiary carbonic acid ester enters the upper end of the first stage continuous water washing kettle of the three-stage continuous countercurrent washing device from the upper end outlet of the continuous phase separator. Feed port, the water phase flowing out from the outlet at the lower end of the second-stage cont...

Embodiment 2

[0051] Repeat the process of embodiment 1, difference is in step (1), the sodium hydroxide that adds changes potassium hydroxide into.

Embodiment 3

[0053] The process of Example 1 was repeated, except that the crude product and sodium ethylate in step (1) were added in a ratio of 5:1 (molar ratio).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com