Waterborne inorganic heat-insulating and corrosion-resistant coating and preparation method thereof

An anti-corrosion coating and inorganic technology, applied in anti-corrosion coatings, alkali metal silicate coatings, coatings, etc., can solve problems such as low adhesion between the heat insulation layer and the anti-corrosion layer, reduced service life of metal structures, and complicated construction. It achieves the effects of excellent heat insulation performance, good flame retardancy and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

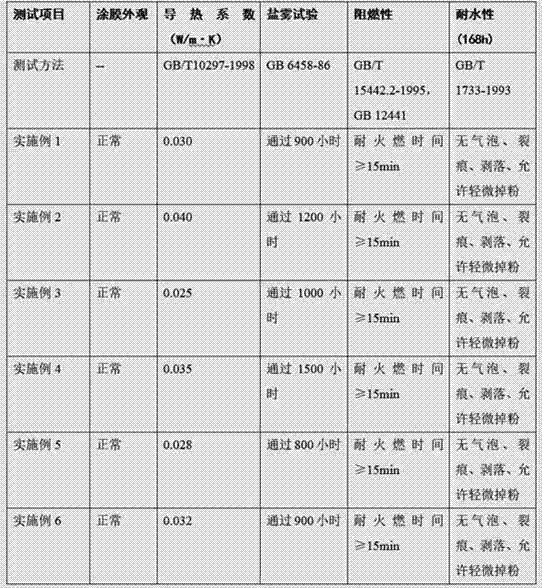

Examples

Embodiment 1

[0024] (1) Preparation of airgel aqueous slurry

[0025] Take 1 mass part of sodium octyl sulfonate surfactant and dissolve it in 100 mass parts of water, add 25 mass parts of airgel powder, and disperse for 2 hours under high-speed stirring at 800 r / min to obtain airgel aqueous slurry ;

[0026] (2) Preparation of thermal insulation inorganic coating

[0027] According to 100 parts by mass of potassium silicate water glass, 50 parts by mass of zirconia nano colloid solution, 1 part by mass of γ-glycidyloxypropyl trimethoxysilane, 8 parts by mass of pure water, 5 parts by mass of zinc powder, 100 parts by mass SiO 2 The ratio of airgel water-based slurry, 8 parts by mass of silicone water-based defoamer, and 0.5 parts by mass of carboxymethylcellulose sodium water-based thickener is mixed together, and the water-based slurry is made by high-speed dispersion, grinding and filtration. Inorganic thermal insulation and anticorrosion coating.

Embodiment 2

[0029] (1) Preparation of airgel aqueous slurry

[0030] Take 2 parts by mass of ammonium laureth sulfate surfactant and dissolve it in 100 parts by mass of water, add 25 parts by mass of airgel powder, and disperse for 1 hour under high-speed stirring at 1500 r / min to obtain airgel water-based slurry;

[0031] (2) Preparation of thermal insulation inorganic coating

[0032] According to 100 parts by mass of lithium silicate water glass, 150 parts by mass of silicon oxide nano colloidal solution, 10 parts by mass of vinyltrimethoxysilane, 10 parts by mass of pure water, 100 parts by mass of aluminum powder, 10 parts by mass of SiO 2 The ratio of airgel water-based slurry, 5 parts by mass of silicone water-based defoamer, and 2 parts by mass of polyacrylamide water-based thickener, mixing all materials together, high-speed dispersion, grinding, and filtration to make water-based inorganic heat insulation Anti-corrosion coating.

Embodiment 3

[0034] (1) Preparation of airgel aqueous slurry

[0035] Take 0.5 parts by mass of tallow trimethylammonium chloride surfactant and dissolve it in 100 parts by mass of water, add 25 parts by mass of airgel powder, and disperse for 0.2h under high-speed stirring at 2000 r / min to obtain airgel Gel aqueous slurry;

[0036] (2) Preparation of thermal insulation inorganic coating

[0037] According to 100 parts by mass of sodium silicate water glass, 100 parts by mass of silica nano colloidal solution, 5 parts by mass of hexamethyldisilazane, 20 parts by mass of pure water, 300 parts by mass of aluminum powder, 150 parts by mass of SiO 2 The ratio of airgel water-based slurry, 2 parts by mass of polyether water-based defoamer, and 5 parts by mass of lethionite water-based thickener is mixed together, and the water-based inorganic separator is made by high-speed dispersion, grinding and filtration. Thermal anti-corrosion coatings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com