Mechanized production process for multi-strain yellow wine raw wheat koji

A technology of raw wheat koji and multi-strain, applied in the field of brewing, can solve the problems of unstable production quality and single strain, and achieve the effects of saving dosage, labor and easy cultivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: the raw wheat koji automatic production method of the multi-bacteria rice wine of artificial inoculation:

[0030] Wort solid medium and bran medium were prepared according to the method described in the summary of the invention.

[0031] Aspergillus niger CCTCCM2015202 and Aspergillus oryzae CCTCCM2015201 were inoculated in eggplant bottle wort solid medium respectively, and cultured at 27°C for 6 days. Wash the spores separately with sterile water to make a spore suspension.

[0032] The spore suspensions of Aspergillus niger and Aspergillus oryzae were respectively inoculated into the bran medium of the Erlenmeyer flask, cultured at 27°C for 6 days, and shaken once every 24h.

[0033] The first-grade bran seeds of Aspergillus niger and Aspergillus oryzae were inoculated into the bran culture medium of the koji culture machine (ZQB-50BJ type koji culture machine) respectively according to the inoculation amount of 1%. The controlled temperature was 28 ℃...

Embodiment 2

[0037] Embodiment 2: the automatic production method of the raw barley koji of multi-bacteria rice wine of artificial inoculation

[0038] Wort solid medium and bran medium were prepared according to the method described in the summary of the invention.

[0039] Aspergillus niger CCTCCM2015202 and Aspergillus oryzae CCTCCM2015201 were inoculated in eggplant bottle wort solid medium respectively, and cultured at 33°C for 4 days. Wash the spores separately with sterile water to make a spore suspension.

[0040] The spore suspensions of Aspergillus niger and Aspergillus oryzae were respectively inoculated into the bran medium of the Erlenmeyer flask, cultured at 33°C for 4 days, and shaken once every 24h.

[0041] The first-grade bran seeds of Aspergillus niger and Aspergillus oryzae were inoculated into the bran culture medium of the koji culture machine (ZQB-50BJ type koji culture machine) respectively according to the inoculation amount of 1%. The controlled temperature was 3...

Embodiment 3

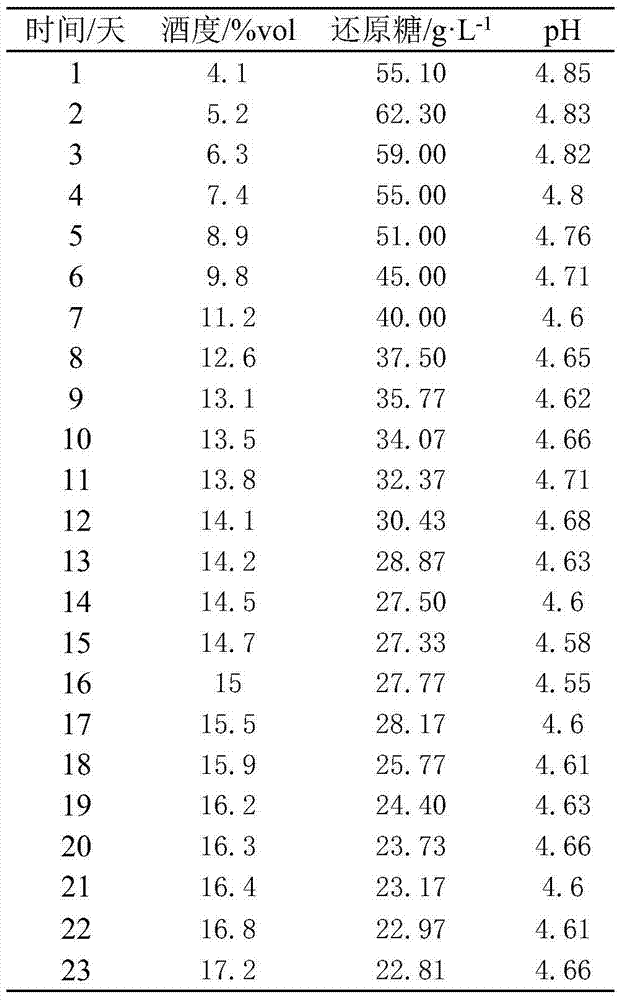

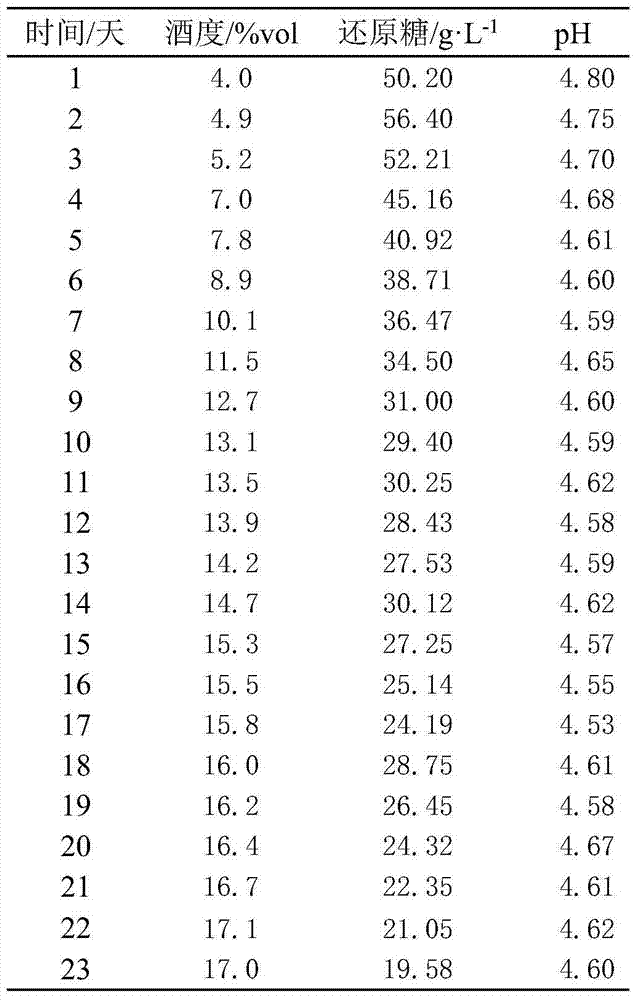

[0044] Example 3: Multi-strain rice wine raw wheat koji applied to rice wine brewing

[0045] (1): Mix 30kg of glutinous rice and 36kg of water, keep warm at 39°C for 14h, and separate the rice and water;

[0046] (2): The soaked glutinous rice is steamed until soft and rotten without white heart, and at the same time, it can be whole without breaking.

[0047] (3): Weigh 0.3kg of commercial Angel rice wine yeast, add it to 3kg of water, and keep warm at 38°C for 30min;

[0048] (4): Put the material obtained in steps 2 and 3 into a fermenter, add 45 kg of water, and 1 kg of raw wheat koji for the above-mentioned multi-bacteria rice wine, stir evenly;

[0049] (5): Control the pre-fermentation temperature to 25°C, lower the temperature to 16°C after 7 days of fermentation, and finish the rice wine brewing after 23 days of fermentation.

[0050] The yellow rice wine of the control group adopts the above-mentioned same process, but the raw wheat koji of the multi-strain yellow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com