Method for preparation of triazole molecularly imprinted electrochemical sensor based on electropolymerized OPD/OAP composite membrane and application thereof

A technology of molecular imprinting and triazoles, which is applied in the direction of material electrochemical variables, can solve the problems affecting the stability and selectivity of polymeric membranes, the number of polar functional groups, and the damage to the endocrine system, etc., and achieves low cost and time-consuming Short, selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

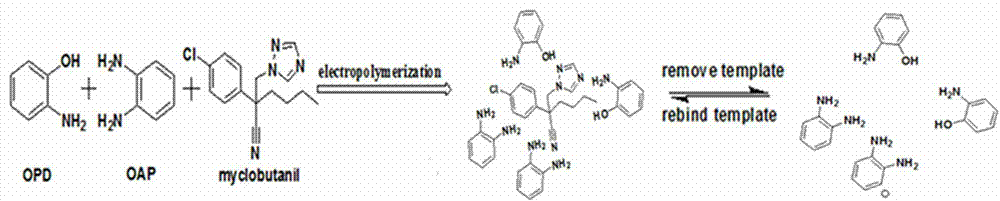

Method used

Image

Examples

Embodiment 1

[0046] Example 1 A preparation method of myclobutanil molecularly imprinted electrochemical sensor

[0047] This embodiment is carried out successively according to the following steps:

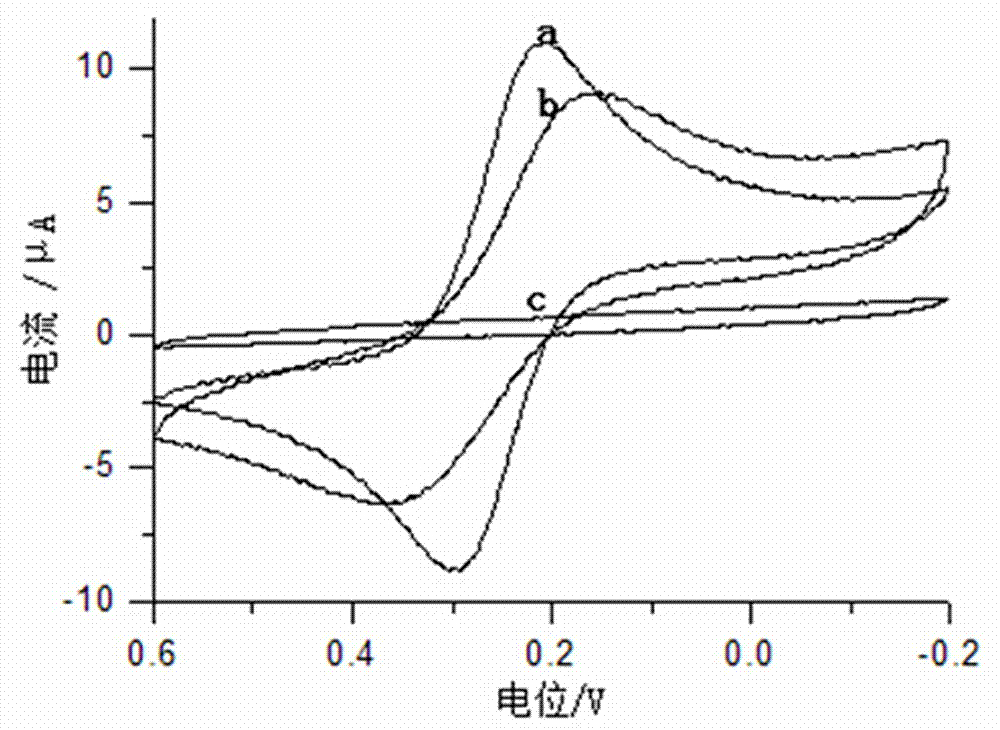

[0048] (11) Glassy carbon electrode pretreatment

[0049] The carbon electrodes were sequentially made of Al 2 o 3 Powder polishing (the polishing in this embodiment is carried out on the suede of the polishing machine. According to the actual situation, this polishing step can also be carried out on other polishing cloths of the conventional polishing machine used for electrode polishing), rinse with ultrapure water After ultrasonic washing in absolute ethanol and ultrapure water, the electrode was placed in 0.5mol / L H 2 SO 4 In solution, cycle scan;

[0050] After taking out the electrode and washing it, place it in the electroactive probe solution, wherein the electroactive probe is potassium ferricyanide, and the electroactive probe solution is 2mmol / L potassium ferricyanide and 1m...

Embodiment 2-6

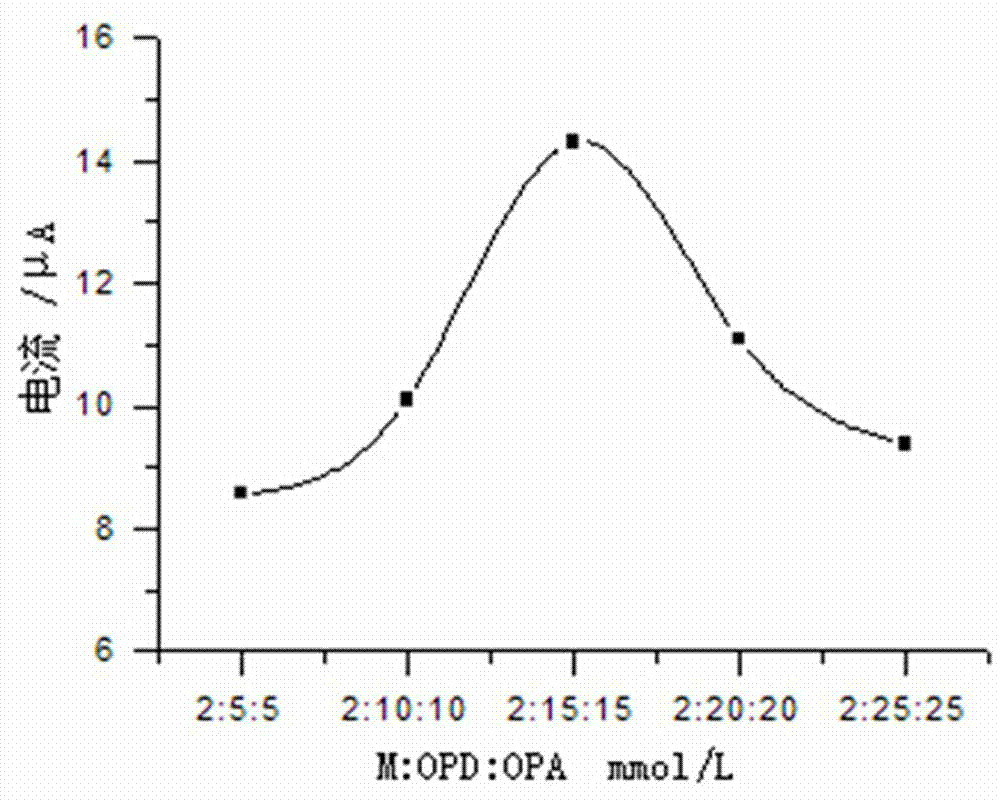

[0059] Example 2-6 Preparation method of myclobutanil molecularly imprinted electrochemical sensor

[0060] This example is a preparation method of myclobutanil molecularly imprinted electrochemical sensor, the preparation steps are the same as in Example 1, the only difference is that the corresponding technical parameters in the preparation process are different, and the specific results are shown in Table 1.

[0061] Table 1 Technical parameter list of the preparation process

[0062]

[0063] The potential intervals of the cyclic scanning in step (x1) (x=2-6) and step (x2) (x=2-6) in the above-mentioned embodiment 2-6 are both -0.5-1.5V.

[0064] The myclobutanazole molecularly imprinted electrochemical sensor prepared in Examples 2-6 has strong selectivity, good stability, high sensitivity, low cost, fast response, simple preparation steps and easy control, and is comparable to other myclobutanazole detection technologies. Compared, the operation process is simple, ...

Embodiment 7

[0065] Example 7 Electropolymerization OPD / OAP Composite Film Thickness Research

[0066] In this example, the thickness of the OPD / OAP composite film prepared in Example 1 is studied, and the thickness of the composite film generated is calculated by the electricity calculation method.

[0067] According to the total electricity generated during the preparation of the myclobutanil molecularly imprinted electrochemical sensor, the thickness of the film was calculated using the electricity calculation method, and the total electricity generated during the polymerization process was 9.3×10 -4 C, the specific calculation formula is as follows:

[0068] d=mQ / (FAρ)

[0069] Where: d-film thickness, nm

[0070] m - the mass of the functional monomer, g;

[0071] Q-the total electricity generated during the polymerization process, C;

[0072] F-Faraday's constant, C / moL;

[0073] A-electrode surface area, cm 2 ;

[0074] Density of ρ-poly OPD / OAP composite film, g / cm 3 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com