Method for recycling natural graphite fine powder as negative pole material

A technology of natural graphite and negative electrode material, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of coating particles sticking together, affecting the electrical properties of graphite, large irreversible capacity, etc., and achieving excellent rate performance and low temperature performance. , the effect of improving product consistency and improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

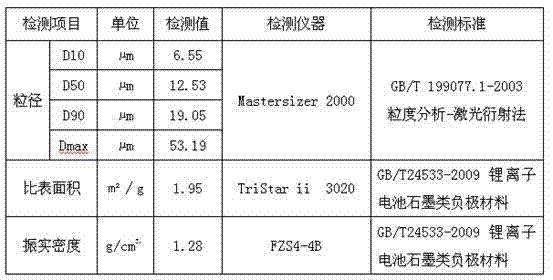

[0027] With 100Kg natural graphite "tailing" (particle size D50=3.46μm, tap density 0.47g / cm 3 , specific surface area 15.6m 2 / g) is raw material, by graphite: pitch: the ratio of pore-forming agent=100:0.2:0.05, takes by weighing the modified coal tar pitch (120 ℃ of softening point) of 20Kg, the epoxy resin (80 ℃ of softening point) of 5Kg, Put them together into a kneader equipped with a heating device, and raise the temperature of the kneader to 140° C. (20° C. higher than the softening point of pitch) while mixing. Mix together for 120 minutes, and then use the kneaded material to notify the tablet press to compress to increase its bulk density. Under the protection of inert gas, the compressed material was raised to 900°C at a rate of 10°C / min, kept for one hour, and then cooled to room temperature.

[0028] The material after high-temperature carbonization is coarsely crushed, shaped and spheroidized to control the particle size Dmax of the material, and the obtained...

Embodiment 2

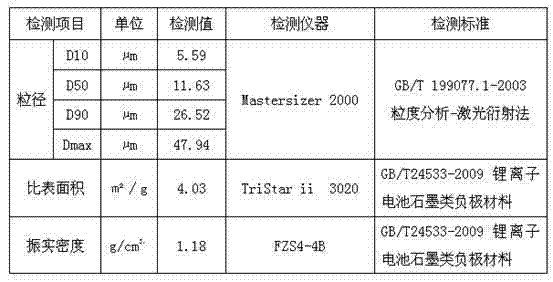

[0033] Take 100Kg natural graphite "tailing" (particle size D50=2.31μm, tap density 0.37 g / cm 3 , specific surface area 18.6㎡ / g) as raw material, according to the weight ratio of graphite: pitch: pore-forming agent = 100:0.1: 0.1 ratio, weigh 10Kg of modified coal tar pitch (softening point 150 ℃), 10Kg of phenolic resin ( softening point 110°C), put them into a kneader equipped with a heating device, and raise the temperature of the kneader to 170°C while mixing. Mix together for 140min, and then use the kneaded material to notify the tablet press to compress to increase its bulk density. Under the protection of inert gas, the compressed material was raised to 950°C at a rate of 5°C / min, kept for one hour, and then cooled to room temperature.

[0034] The material after high-temperature carbonization is coarsely crushed, shaped and spheroidized to control the particle size Dmax of the material, and the obtained particle size D50 is 12.71 μm, and the tap density is 0.94 g / cm ...

Embodiment 3

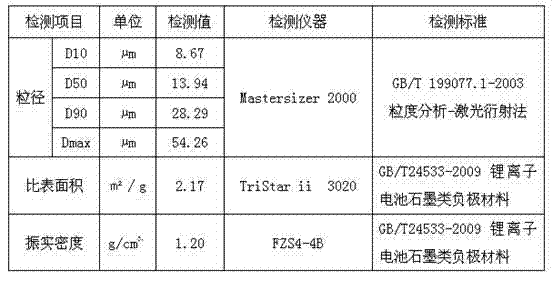

[0039] Take 100Kg natural graphite "tailing" (particle size D50=6.16μm, tap density 0.59g / cm 3 , specific surface area 14.54㎡ / g) as raw material, according to the weight ratio of graphite: pitch: pore forming agent = 100:0.4: 0.1 ratio, weigh 40Kg of modified coal tar pitch (softening point 100 ℃), 10Kg of polyamide resin (softening point 80° C.), put them into a kneader equipped with a heating device together, and raise the temperature of the kneader to 130° C. while mixing. Mix together for 150 minutes, and then use the kneaded material to notify the tablet press to compress to increase its bulk density. Under the protection of an inert gas, the compressed material was raised to 1000°C at a rate of 10°C / min, kept at this temperature for half an hour, and then cooled to room temperature.

[0040] The material after high-temperature carbonization is coarsely crushed, shaped and spheroidized to control the particle size Dmax of the material, and the obtained particle size D50 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com