Comprehensive treatment method for waste fused salts and dust collection slag produced through titanium tetrachloride fused salt chlorination

A technology of molten salt chlorination and titanium tetrachloride, which can be used in the removal of solid waste and other directions, can solve problems such as environmental pollution, and achieve the effect of reducing huge pressure, improving industrial application prospects, and solving recycling problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

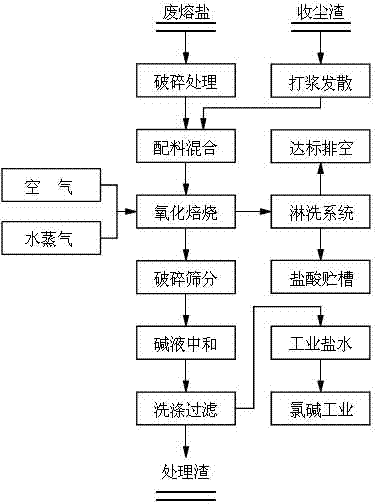

[0033] Such as figure 1 As shown, a comprehensive treatment method for the chlorination of titanium tetrachloride molten salt to produce waste molten salt and dust collection slag: First, the waste molten salt discharged from the molten salt chlorination furnace is crushed by a jaw crusher, and the The processed broken slag is pulverized to 80 mesh with a grinder; the dust collection slag produced during the production of molten salt chlorination is slurried and dispersed at room temperature 20 ℃, and prepared into a solid-liquid mixture; mixed waste molten salt grinding powder with solid-liquid The mixture is prepared by mixing the ingredients of the dust collecting slag into a mixture. The mass ratio of the waste molten salt slag and the dust collecting slag is 1.5:1; the mixture is oxidized and roasted under the atmosphere of air and water vapor. The oxidation roasting equipment is a tunnel In the kiln, the oxidation roasting temperature is 600℃, the oxidation roasting time ...

Embodiment 2

[0035] Such as figure 1 As shown, a comprehensive treatment method for the chlorination of titanium tetrachloride molten salt to produce waste molten salt and dust collection slag: First, the waste molten salt discharged from the molten salt chlorination furnace is crushed by a jaw crusher, and the The crushed slag after treatment is pulverized to 100 mesh with a mill; the dust collection slag generated during the production of molten salt chlorination is slurried and dispersed at room temperature 20 ℃ to prepare a solid-liquid mixture; the waste molten salt grinding powder is mixed with solid-liquid The mixture is prepared by mixing the ingredients of the dust collection slag into a mixture. The mass ratio of the waste molten salt slag and the dust collection slag is 1:1; the mixture is oxidized and roasted under the atmosphere of air and water vapor, and the oxidation roasting equipment is flamed back In the kiln, the oxidation roasting temperature is 700℃, the oxidation roas...

Embodiment 3

[0037] Such as figure 1 As shown, a comprehensive treatment method for the chlorination of titanium tetrachloride molten salt to produce waste molten salt and dust collection slag: First, the waste molten salt discharged from the molten salt chlorination furnace is crushed by a jaw crusher, and the The crushed slag after treatment is pulverized to 160 mesh with a grinder; the dust collection slag produced during the production of molten salt chlorination is slurried and dispersed at room temperature 20 ℃ to prepare a solid-liquid mixture; the waste molten salt grinding powder is mixed with solid-liquid The mixture is prepared by mixing the ingredients of the dust collection slag into a mixture. The mass ratio of the waste molten salt slag and the dust collection slag is 1:1; the mixture is oxidized and roasted under the atmosphere of air and water vapor, and the oxidation roasting equipment is flamed back In the kiln, the oxidation roasting temperature is 400°C, the oxidation r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com