Application method of overhead type in-situ infrared analytic system

An in-situ infrared and analysis system technology, applied in the direction of material analysis, material analysis through optical means, and measuring devices, can solve the problems of complex reaction devices and complex structures, and achieve low manufacturing costs, simple manufacturing, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

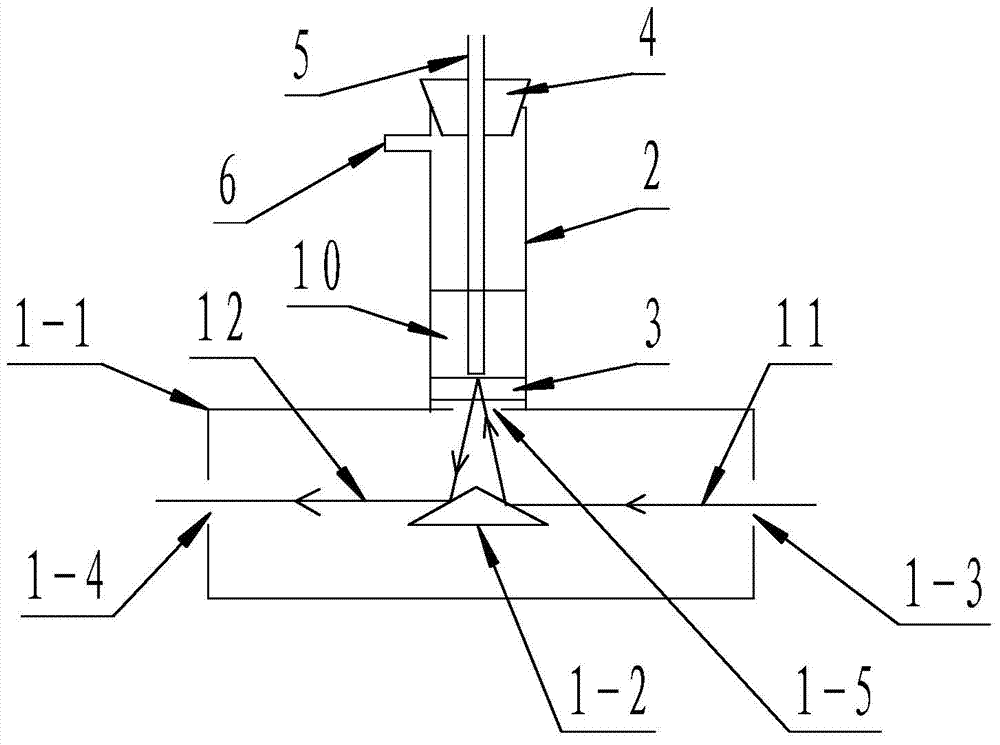

Embodiment 1

[0028] Such as figure 2 , in order to detect the reactivity of the sample catalyst 10 at different temperatures, the reaction tube 2 is made of stainless steel, the infrared window 3 is made of potassium bromide window, the sealing plug 4 and the outlet pipe 5 are removed, and the 13X molecular sieve sample catalyst 10 is packed in The bottom of the reaction tube 2 is in contact with the infrared window 3, and the sealing plug 4 is covered. At the same time, the lower nozzle of the outlet pipe 5 is inserted into the sample catalyst 10, and the upper nozzle of the outlet pipe 5 is connected to the mass spectrometer. The metal shell 1- The light exit hole 1-4 of 1 is connected to the spectrum acquisition analyzer, the outer periphery of the reaction tube 2 is provided with a heating wire 7-1, and the hole on one side of the central hole of the sealing plug 4 is provided with a thermocouple 7-2, containing NO, NH3, O2 , N2 mixed gas enters the reaction tube 2 from the inlet 6, p...

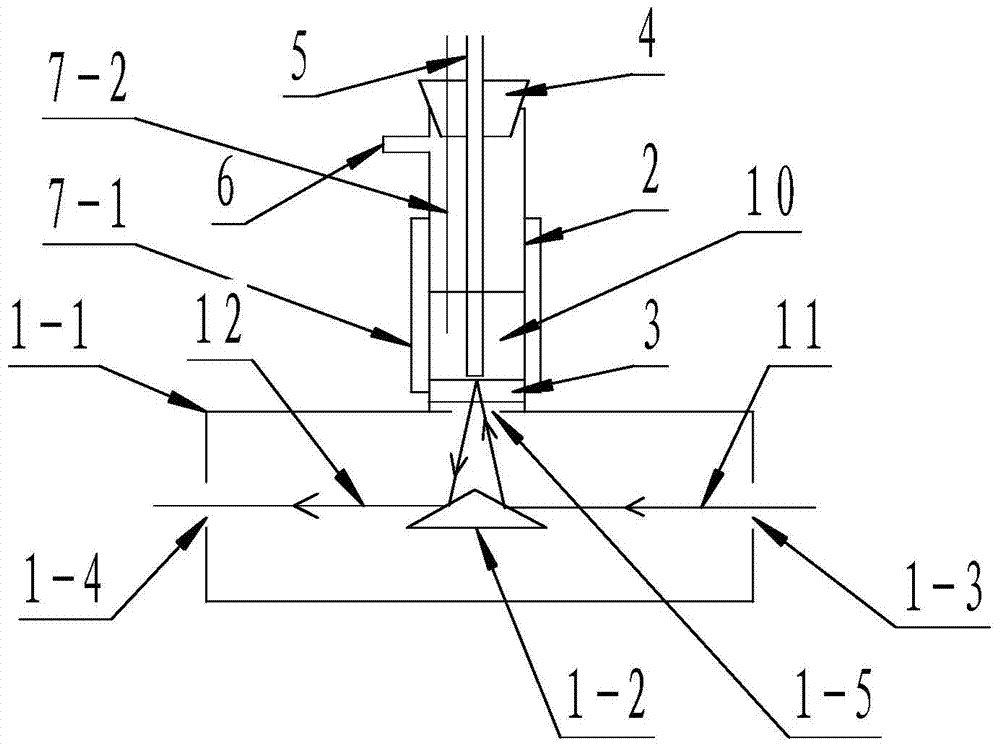

Embodiment 2

[0030] Such as image 3, in order to detect the reactivity of the sample catalyst 10 under the influence of the plasma external field, the reaction tube 2 is made of quartz glass, the infrared window 3 is made of zinc sulfide window, the sealing plug 4 is made of rubber, and the sealing plug 4 and the gas outlet pipe 5 are removed. Fill the sample catalyst 10 in the bottom of the reaction tube 2, contact the infrared window 3, cover the sealing plug 4, and insert the lower nozzle of the outlet pipe 5 into the sample catalyst 10, and connect the upper nozzle of the outlet pipe 5 to the chromatographic analysis instrument, the light exit hole 1-4 of the metal shell 1-1 is connected to the spectrum acquisition analyzer, the outer periphery of the reaction tube 2 is provided with a high-voltage electrode 8-1, and the outlet pipe 5 adopts a hollow copper tube as the low-voltage electrode 8-2; the high-voltage electrode 8 -1 and the low-voltage electrode 8-2 generate an external pla...

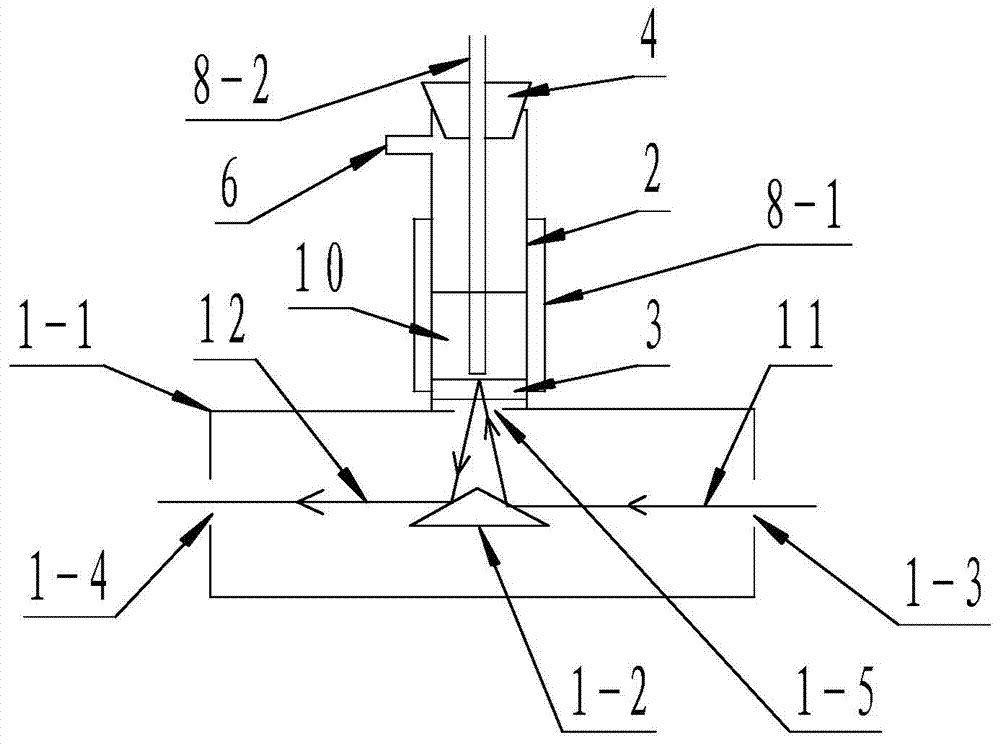

Embodiment 3

[0032] Such as Figure 4 , in order to detect the reactivity of the sample catalyst 10 under the influence of a microwave external field, the reaction tube 2 is made of quartz glass, the infrared window 3 is made of zinc sulfide window, the sealing plug 4 and the gas outlet pipe 5 are removed, and the sample catalyst 10 is filled in the reaction tube. The bottom of the tube 2 is in contact with the infrared window 3, and the sealing plug 4 is covered. At the same time, the lower nozzle of the outlet pipe 5 is inserted into the sample catalyst 10, and the upper nozzle of the outlet pipe 5 is connected to the chromatographic analyzer. The metal shell 1-1 The light exit hole 1-4 of the light outlet is connected to the spectrum acquisition analyzer, the microwave metal shell 9-1 is arranged outside the reaction tube 2 above the metal shell 1-1, and the nozzles of the air inlet 6 and the air outlet pipe 5 are set on the microwave metal shell 9 -1, a waveguide 9-3 is arranged betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com