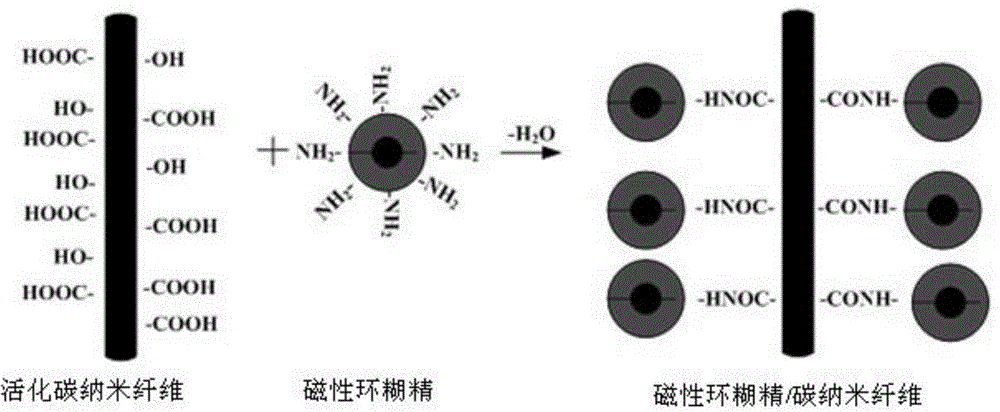

Magnetic cyclodextrin-carbon nanofiber composite material and preparation method thereof

A technology of carbon nanofibers and composite materials, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., can solve the problems of unstable chemical properties, poor mechanical properties, long adsorption time, etc., to achieve improved stability, Improves the adsorption rate and adsorption capacity, and increases the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] Example 1: Preparation of carbon nanofiber / magnetic cyclodextrin adsorption material

[0031] A. Preparation of functionalized carbon nanofibers

[0032] Put 0.5g of polyacrylonitrile nanofibers into a tube furnace, raise it from room temperature to 200°C, and then keep it for 3.5h for pre-oxidation treatment; then, under the protection of nitrogen, raise it to 1300°C for high-temperature pyrolysis, and cool naturally Carbon nanofibers can be obtained at room temperature.

[0033] Add 0.1 g of carbon nanofibers to 20 mL of concentrated nitric acid, heat to reflux in a water bath at 70°C, react for 16 minutes, stir in an ice bath for 1 hour, centrifuge, wash with dilute hydrochloric acid and ethanol in sequence, and dry to obtain functionalized carbon nanofibers.

[0034] B. Preparation of Magnetic Cyclodextrins

[0035] Prepare FeCl with a molar ratio of 2:1 3 with FeCl 2 Mixed solution 20mL, FeCl 3 and FeCl 2 The total mass of 0.35g was added to 20mL of ammonia w...

example 2

[0038] Example 2: Preparation of carbon nanofiber / magnetic cyclodextrin adsorption material

[0039] A. Preparation of functionalized carbon nanofibers

[0040] Put 0.5g of polyacrylonitrile nanofibers into a tube furnace, raise it from room temperature to 240°C, and then keep it for 3 hours for pre-oxidation treatment; then, under the protection of nitrogen, raise it to 1400°C for high-temperature pyrolysis, and cool naturally Carbon nanofibers can be obtained at room temperature.

[0041] Add 0.1 g of carbon nanofibers to 20 mL of concentrated nitric acid, heat to reflux in a water bath at 75°C, react for 18 min, stir in an ice bath for 1 h, centrifuge, wash with dilute hydrochloric acid and ethanol in sequence, and dry to obtain functionalized carbon nanofibers.

[0042] B. Preparation of Magnetic Cyclodextrins

[0043] Prepare FeCl with a molar ratio of 2:1 3 with FeCl 2 Mixed solution 20mL, FeCl 3 and FeCl 2The total mass of the solution is 0.45g, add 15mL of 20% am...

example 3

[0046] Example 3: Preparation of carbon nanofiber / magnetic cyclodextrin adsorption material

[0047] A. Preparation of functionalized carbon nanofibers

[0048] Put 0.5g of polyacrylonitrile nanofibers into a tube furnace, raise it from room temperature to 220°C, and then keep it for 3.5h for pre-oxidation treatment; then, under the protection of nitrogen, raise it to 1500°C for high-temperature pyrolysis, and cool naturally Carbon nanofibers can be obtained at room temperature.

[0049] Add 0.1 g of carbon nanofibers to 19 mL of concentrated nitric acid, heat to reflux in a water bath at 80°C, react for 18 minutes, stir in an ice bath for 1 hour, centrifuge, wash with dilute hydrochloric acid and ethanol in sequence, and dry to obtain functionalized carbon nanofibers.

[0050] B. Preparation of Magnetic Cyclodextrins

[0051] Prepare FeCl with a molar ratio of 2:1 3 with FeCl 2 Mixed solution 20mL, added FeCl 3 and FeCl 2 The total mass of 0.25g was added to 17mL of 17%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com