Preparation method of three-dimensional macroporous carbon/carbon nanotube/titanium dioxide/silver composite material capable of catalytically degrading unsymmetrical dimethylhydrazine

A carbon nanotube, three-dimensional macroporous technology, applied in the environmental field, can solve the problems such as the catalyst cannot be effectively reused, the cost of sewage treatment is unbearable, and the recovery of nanoparticles is difficult, and achieves easy recovery, strong structure, and reduced band gap. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

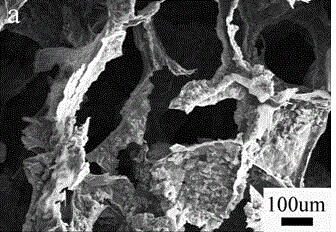

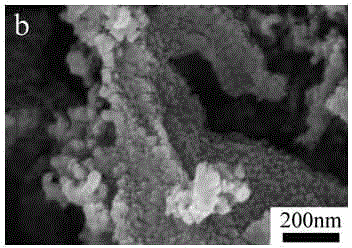

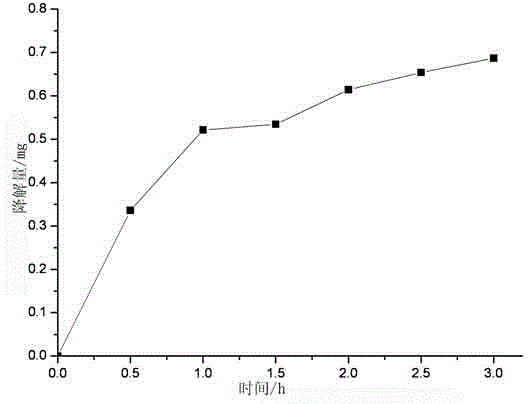

Image

Examples

Embodiment 1

[0029] 1. Preparation process:

[0030] 1. Disperse 0.5g of purchased acidified carbon nanotubes into 25g of a mixed solvent of ethanol and water with a volume ratio of 1:3, and disperse for 10 minutes under ultrasonic conditions with a power of 400W to obtain a carbon nanotube mixture. The concentration of carbon nanotubes in the nanotube mixture liquid is 2wt%.

[0031] 2. Weigh 10g of phenolic resin and 1g of curing agent hexamethylenetetramine and mix them with 40g of ethanol solvent. Under ultrasonic conditions with a power of 400W, after 30 minutes, a 20wt% mixture of phenolic resin is formed.

[0032] 3. Cut and weigh 1g of polyurethane foam template with a thickness of 4mm, first absorb the carbon nanotube mixture, then dry it at 60°C, then absorb the phenolic resin mixture, repeat 5 times, and ensure that the last time is to absorb Phenolic resin mixture until the template is cross-linked and solidified.

[0033] 4. Place the prepared composite foam in a pyrolysis f...

Embodiment 2

[0044] 1. Preparation process:

[0045] 1. Disperse 1.35g of purchased acidified carbon nanotubes into 25g of a mixed solvent of ethanol and water with a volume ratio of 1:2, and disperse for 10 minutes under ultrasonic conditions with a power of 400W to obtain a carbon nanotube mixture. The concentration of carbon nanotubes in the nanotube mixture liquid is 5wt%.

[0046] 2. Weigh 20g of phenolic resin and 2g of curing agent hexamethylenetetramine and mix them with 46g of ethanol solvent. Under ultrasonic conditions with a power of 400W, after 30 minutes, a 30wt% mixture of phenolic resin is formed.

[0047] 3. Cut and weigh 2.7g of a polyurethane foam template with a thickness of 4mm, first absorb the carbon nanotube mixture, then dry it at 60°C, then absorb the phenolic resin mixture, repeat 4 times, and ensure that the last time is Aspirate the phenolic resin mixture until the template is cross-linked and solidified.

[0048] 4. Place the prepared composite foam in a pyr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com