Inorganic/organic hybrid epoxy resin reinforcing agent

An epoxy resin and reinforcing agent technology, applied in the field of composite materials, can solve the problems of material heat resistance, hardness, modulus, electrical properties, limited impact resistance and fracture resistance, and high cross-linking degree of epoxy resin. Achieve excellent product performance, improve toughness, improve mechanical properties and thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

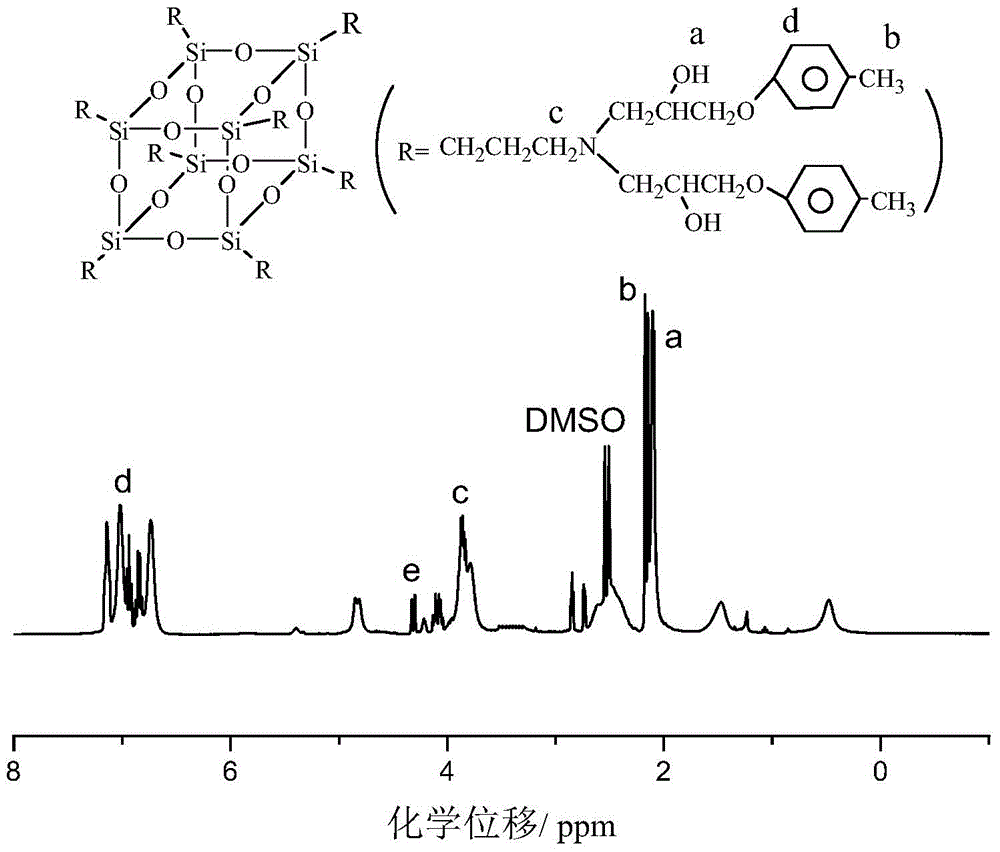

[0024] Embodiment one: a kind of synthetic method of inorganic / organic hybrid epoxy resin reinforcing agent comprises the following steps:

[0025] 1. Make p-cresyl glycidyl ether into a 20wt% methanol solution, place it in a 250mL three-necked flask, and add the calculated amount of KH550 dropwise, according to the molar ratios of KH550 and TGE are 1:6, 1:8, 1 :10, 1:12, and 1:14 were added, mechanically stirred in a constant temperature water bath at 60°C for 3 hours, and then the reaction was stopped. After adding excess tetrahydrofuran, a white precipitate was obtained, filtered under reduced pressure and dried, cooled to room temperature, and reduced After pressure filtration and drying, a white solid was obtained, named PESi1, PESi2, PESi3, PESi4, PESi5, and the yield was 80%-83%.

[0026] 2. Make a mixed solvent of acetonitrile and propanol according to the volume ratio of 1:2, and dissolve PESi1, PESi2, PESi3, PESi4, and PESi5 in the mixed solvent of acetonitrile and p...

Embodiment 2

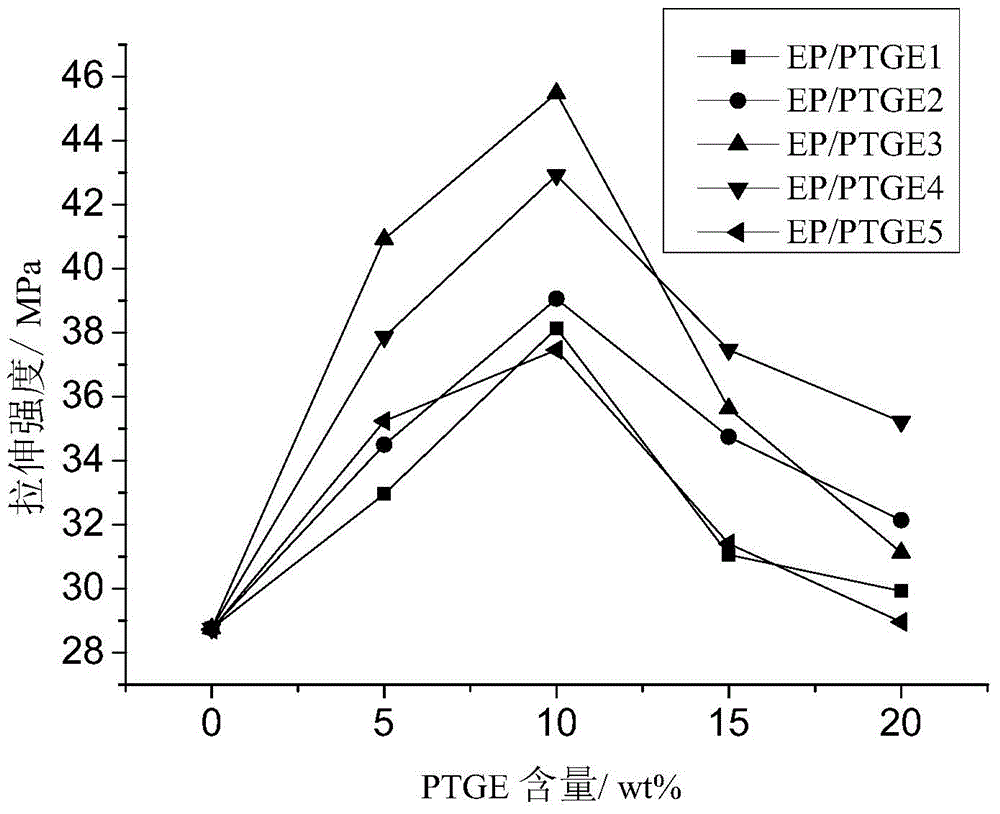

[0027] Example 2: Preparation of Hybrid Modified Epoxy Resin Composite Material

[0028] The inorganic / organic hybrid epoxy resin reinforcing agent obtained by the method of Example 1 is added to the epoxy resin E44 respectively, and the weight ratio of the reinforcing agent to the epoxy resin is controlled to be 5:100~20:100, Stir to mix the two completely evenly, then mechanically stir in an oil bath at 70°C for 3 hours, add 5-10% of the weight of epoxy resin diethyltolyldiamine as a curing agent, place in an oven at 70°C for 2 hours After the air bubbles are completely removed, pour it into a dumbbell-shaped mold that has been sprayed with a release agent, raise the temperature of the oven to 130°C, and take it out after the material is cured to obtain a transparent composite material EP / PTGE. Run performance tests.

Embodiment 3

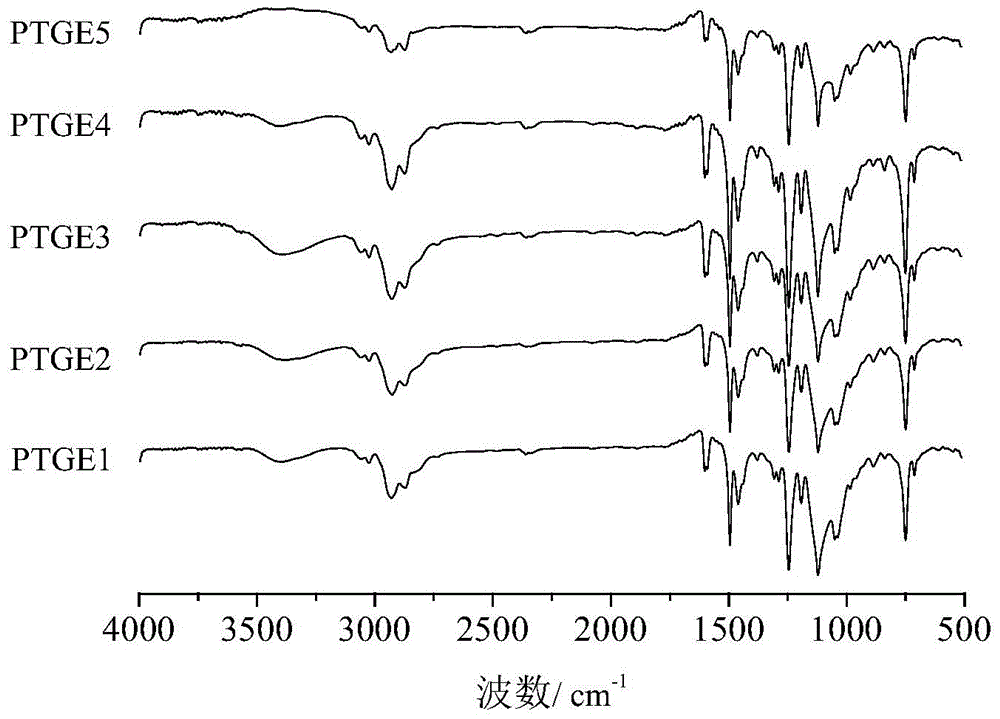

[0029] Embodiment 3: Infrared analysis of a kind of inorganic / organic hybrid

[0030] Adopt Fourier transform infrared spectrometer to carry out infrared characterization to the inorganic / organic hybrid obtained by the method of Example 1, and the scanning range is 4000~500cm -1 In the range of wavenumbers, the resolution is 4cm -1 , see attached figure 1 . On the infrared spectrum, 3387cm -1 The absorption peak is the N-H stretching vibration peak. In the spectrum of PTGE, the intensity of the N-H vibration peak weakens in turn, while the peak basically disappears in the spectrum of PTGE5; at the same time, at 1598cm -1 and 1496cm -1 The obvious vibration of the benzene ring skeleton is found at the position, indicating that the epoxy group in p-cresyl glycidyl ether is compatible with POSS-NH 2 -NH in 2 A ring-opening addition reaction has occurred; and the content increases with the increase of the amount of p-cresyl glycidyl ether; while the secondary alcohol is at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com