Method for preparing distillation film with support body

A technology of distillation membrane and support body is applied in the field of preparation of distillation membrane with support body, which can solve the problems of weak anti-pollution ability of microporous membrane, uncontrollable pore size and high preparation cost, and achieves good anti-pollution performance, The membrane pores are uniform and easy to control, and the mass transfer resistance is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

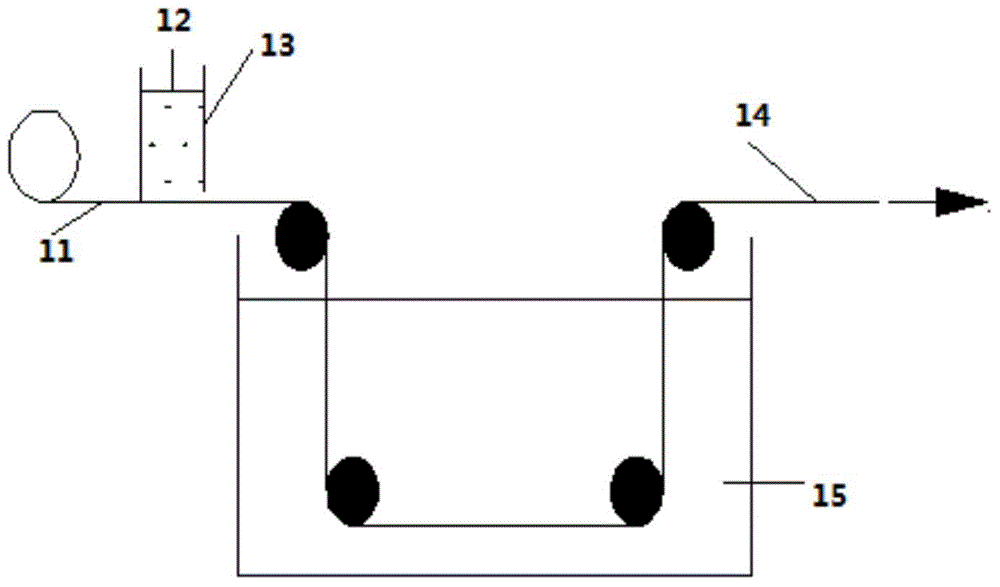

[0034] First, the PVDF powder was vacuum-dried at 60°C for 24 hours, and the dried PVDF and PVP powders were added in proportions of 14% and 4% to the flasks containing 5% and 78% PDMS and DMAC solutions and stirred for 24 hours to obtain transparent Uniform casting solution, let stand for 24h to defoam. Pour the casting liquid onto a clean glass plate attached to a polyester screen, and quickly and evenly distribute it with a scraper with a certain thickness. In deionized water, after 10 minutes, take out the glass plate and put it in a large amount of deionized water, soak the membrane in water for at least 3 days, and change the deionized water frequently to completely remove the residual solvent.

[0035] Distilled membranes were prepared according to the following parameters:

[0036]

[0037]

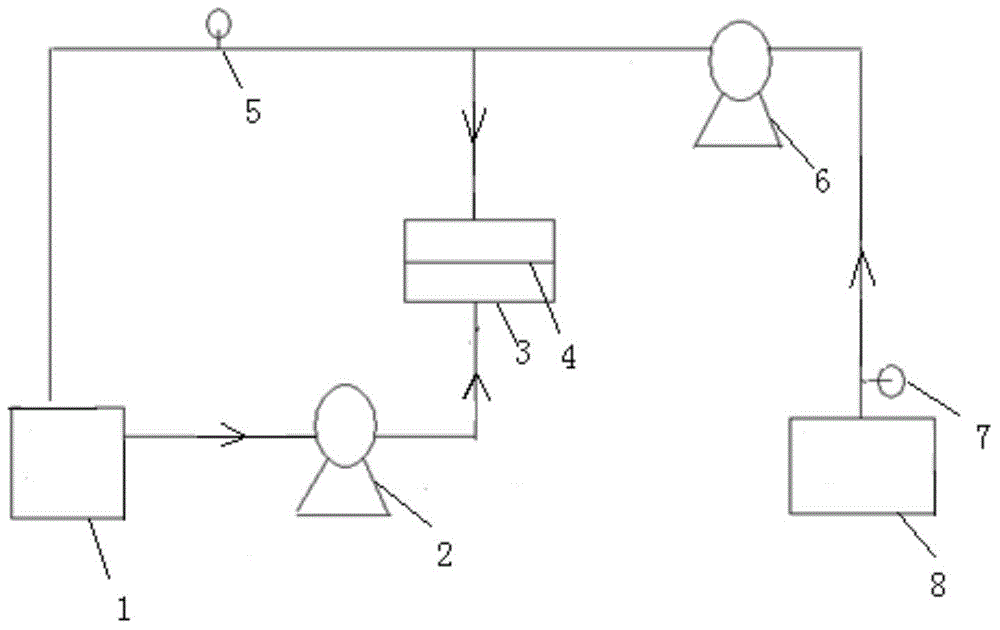

[0038] The above-prepared distillation membranes were subjected to membrane distillation experiments, see figure 2 , using direct contact, the hot end is a 5% Nacl soluti...

Embodiment 2

[0040] First, the PVDF powder was vacuum-dried at 65°C for 24 hours, and the dried PVDF and PVP powders were added in proportions of 12% and 6% to flasks containing 5% and 77% PDMS and DMAC solutions and stirred for 24 hours to obtain transparent Uniform casting solution, let stand for 24h to defoam. Pour the film-casting liquid onto a clean glass plate attached to a polyester screen, and quickly and evenly distribute it with a scraper with a certain thickness. In the process of deionization, after 10 minutes, take out the glass plate and put it in a large amount of deionized water, and store it for at least 3 days, and the deionized water must be changed frequently to completely remove the residual solvent.

[0041] The preparation of the distillation membrane was carried out according to the following parameters:

[0042]

[0043]

[0044] The membrane distillation experiment of the obtained distillation membrane is the same as that in Example 1. The test results of ...

Embodiment 3

[0046] First, the PVDF powder was vacuum-dried at 70°C for 24 hours, and the dried PVDF and PVP powders were added in proportions of 13% and 2% to the flasks containing 5% and 79% PDMS and DMAC solutions and stirred for 24 hours to obtain transparent Uniform casting solution, let stand for 24h to defoam. Pour the film-casting liquid onto a clean glass plate attached to a polyester screen, and quickly and evenly distribute it with a scraper with a certain thickness. In deionized water, after 10 minutes, take out the glass plate and put it in a large amount of deionized water, keep it for at least 3 days, and change the deionized water frequently to completely remove the residual solvent.

[0047] Distilled membranes were prepared according to the following parameters:

[0048]

[0049] The membrane distillation experiment of the obtained distillation membrane is the same as that in Example 1. The test result of the distillation membrane is that the permeation flux can reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com