Modified macadamia shell adsorbent

A nut shell and adsorbent technology, which is applied in the field of biomass modified adsorbent materials, can solve the problems that have not been reported, and achieve the effects of no waste discharge, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

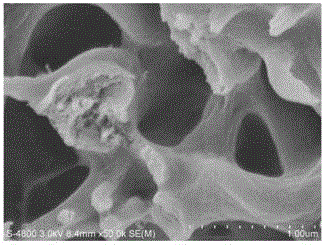

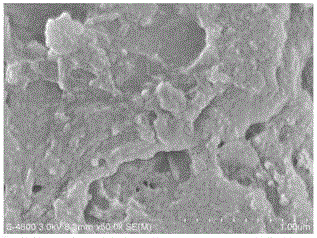

Image

Examples

Embodiment 1

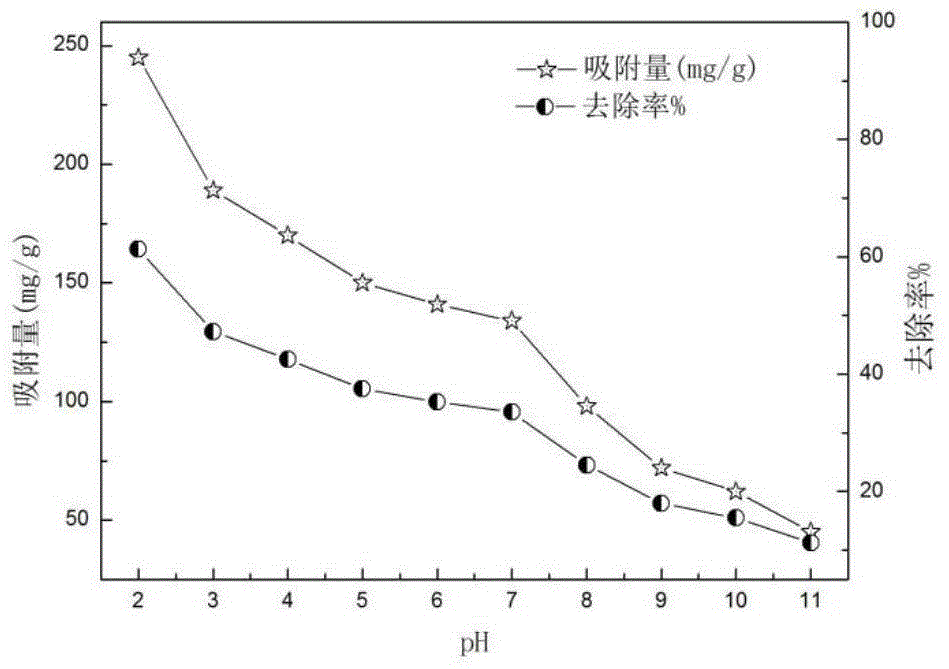

[0036] As shown in Table 1, the adsorption capacity of the adsorbent obtained by the preparation method of the present invention for reactive brilliant red dye is obviously better in an acidic environment, and can reach 240-250mg / g;

[0037] The specific preparation method thereof is: a preparation method of a modified macadamia nut shell adsorbent, the steps of which include:

[0038] (1) Wash the macadamia nut shells, put them in a pulverizer, pulverize them, and then sieve them to obtain macadamia nut shell powder;

[0039] (2) The macadamia nut shell powder and tartaric acid obtained in step (1) are calculated as 1g powder, and 2g tartaric acid is added to mix, and the sulfuric acid of 1ml and the deionized water of 20ml are added thereto, and then after it is stirred evenly, use Boil at a temperature of 50°C for 120 minutes, then cool it down to normal temperature, and wash the boiled macadamia nut shell powder with deionized water until the pH value of the macadamia nut ...

Embodiment 2

[0049] A method for preparing a modified macadamia nut shell adsorbent, the steps comprising:

[0050] (1) Wash the macadamia nut shells, put them in a pulverizer, pulverize them, and then sieve them to obtain macadamia nut shell powder;

[0051] (2) The macadamia nut shell powder obtained in step (1) and tartaric acid are calculated as 1g powder, and 3g tartaric acid is added to mix, and the sulfuric acid of 3ml and the deionized water of 30ml are added thereto, and after it is stirred evenly, use Boil at 70°C for 200 minutes, then cool it down to normal temperature, and wash the boiled macadamia nut shell powder with deionized water until the pH value of the macadamia nut shell powder is neutral. Put it in a baking oven and dry it at a temperature of 105°C;

[0052] (3) Put the dried powder obtained in step (2) and 20ml of ammonia water, and place it at a temperature of 70°C for constant temperature stirring for 30 minutes, then place it in a condensing reflux device for co...

Embodiment 3

[0061] A method for preparing a modified macadamia nut shell adsorbent, the steps comprising:

[0062] (1) Wash the macadamia nut shells, put them in a pulverizer, pulverize them, and then sieve them to obtain macadamia nut shell powder;

[0063] (2) Add 2.5 g of tartaric acid to the macadamia nut shell powder obtained in step (1) and tartaric acid as 1 g of powder, mix, and add 2 ml of sulfuric acid and 25 ml of deionized water to it, and then stir it evenly, Boil at a temperature of 60°C for 170 minutes, then cool it down to normal temperature, and wash the boiled macadamia nut shell powder with deionized water until the pH value of the macadamia nut shell powder is neutral. Put it into a baking oven and dry it at a temperature of 85°C;

[0064] (3) Add the dried powder obtained in step (2) and 15ml of ammonia water, and place it at a temperature of 60°C for constant temperature stirring for 25 minutes, and then place it in a condensing reflux device for condensing and refl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| pulverization | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com