Titanium oxide/tungsten oxide nano-composite film on surface of metallic titanium, preparation and application

A nanocomposite, metal titanium technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, chemical/physical process, physical/chemical process catalyst, etc., can solve complex process, poor bonding force between film layer and substrate , large interfacial resistance, etc., to achieve the effects of electron transport, good photocatalysis, and good contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of the titanium oxide / tungsten oxide nanocomposite film on the surface of metal titanium comprises the following steps:

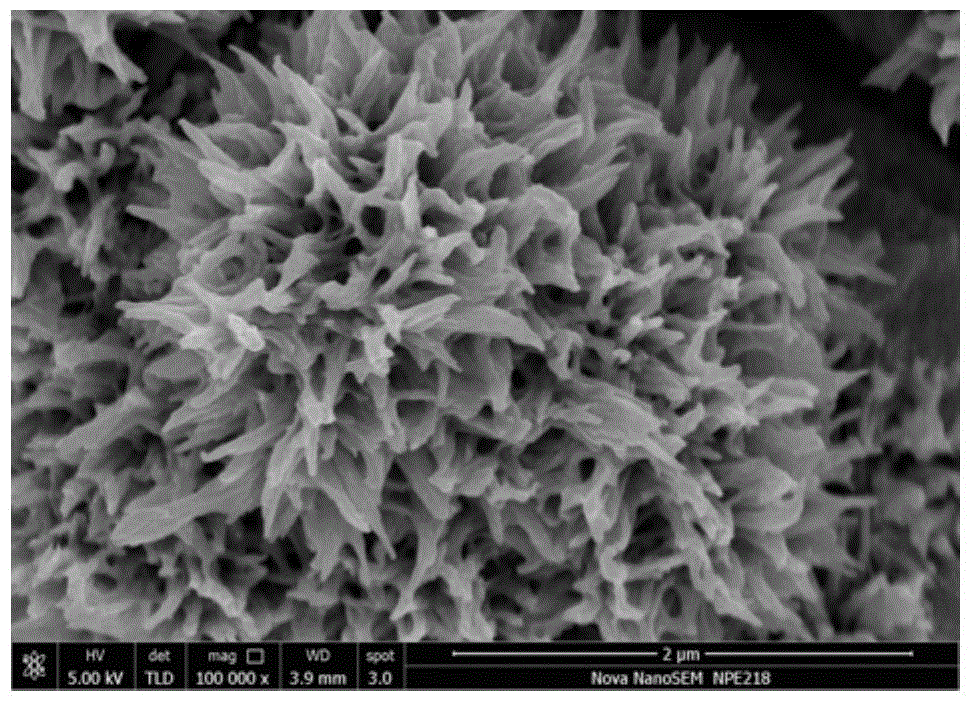

[0025] (1) Cut the pre-polished and cleaned titanium metal sheet into a size of 4cm×4cm, etch it with hydrofluoric acid / nitric acid, take it out, wash it with deionized water and dry it in the air. (2) Immerse the clean metal titanium sheet in a closed reactor containing 50 ml of oxidizing solution of 1% peroxytungstic acid and 5% hydrogen peroxide, and keep it in an oven at 80° C. for 12 hours. (3) After taking out the oxidized metal titanium sheet, washing and drying, in a pure oxygen atmosphere, the temperature was raised to 500°C at 1°C / min and baked for 12 hours to prepare a titanium oxide / tungsten oxide nanocomposite film. SEM images of the film surface are shown in figure 1 , the nanostructure of the oxide can be clearly distinguished as a flower-like structure assembled by nanoribbons. Among them, titanium oxide is ma...

Embodiment 2

[0027] The preparation method of the titanium oxide / tungsten oxide nanocomposite film on the surface of metal titanium comprises the following steps:

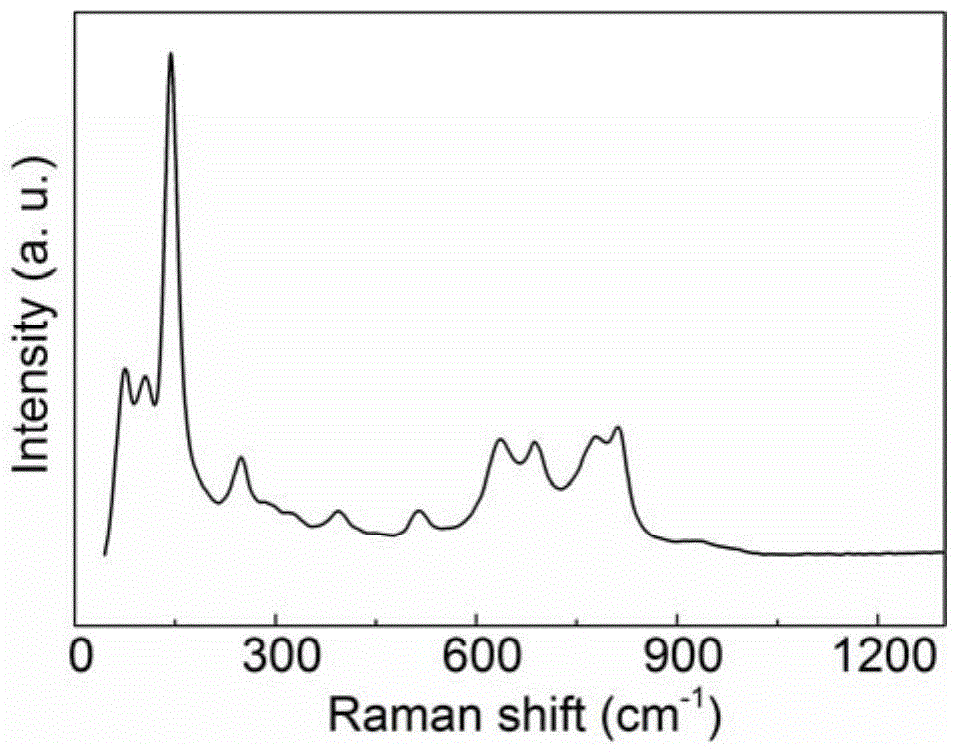

[0028] (1) Cut the pre-polished and cleaned titanium sheet into a size of 2cm×2cm, etch it with hydrofluoric acid / nitric acid, take it out, wash it with deionized water and dry it in the air. (2) Immerse the clean metal titanium sheet in a closed reactor containing 20 ml of 0.5% peroxytungstic acid and 5% hydrogen peroxide oxidation solution, (3) keep it in an oven at 80°C for 72 hours. The titanium oxide / tungsten oxide nanocomposite film can be prepared by taking out the oxidized metal titanium sheet, washing and drying it, and then heating it up to 600°C at a rate of 5°C / min for 2 hours in an air atmosphere. figure 2 It is the Raman spectrum of the film surface, which can distinguish the anatase TiO 2 and hex WO 3 characteristic Raman peaks.

Embodiment 3

[0030] The preparation method of the titanium oxide / tungsten oxide nanocomposite film on the surface of metal titanium comprises the following steps:

[0031](1) Cut the pre-polished and cleaned titanium metal sheet into a size of 1cm×1cm, etch it with hydrofluoric acid / nitric acid, take it out, wash it with deionized water and dry it in the air. (2) Immerse the clean metal titanium sheet in a closed reactor containing 10 ml of 5% peroxytungstic acid and 1% hydrogen peroxide oxidation solution, and keep it in an oven at 100° C. for 12 hours. (3) After taking out the oxidized metal titanium sheet, washing and drying, in an oxygen atmosphere, the temperature was raised to 400°C at 0.5°C / min and baked for 3 hours to prepare a titanium oxide / tungsten oxide nanocomposite film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com