Soldering flux for confluence strap of solar cell module and preparation method of soldering flux

A solar cell and solder technology, applied in welding equipment, welding/cutting media/materials, welding media, etc., can solve problems that affect the efficacy of components, and achieve the effects of improving solderability, increasing peel strength, and reducing the melting point of alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

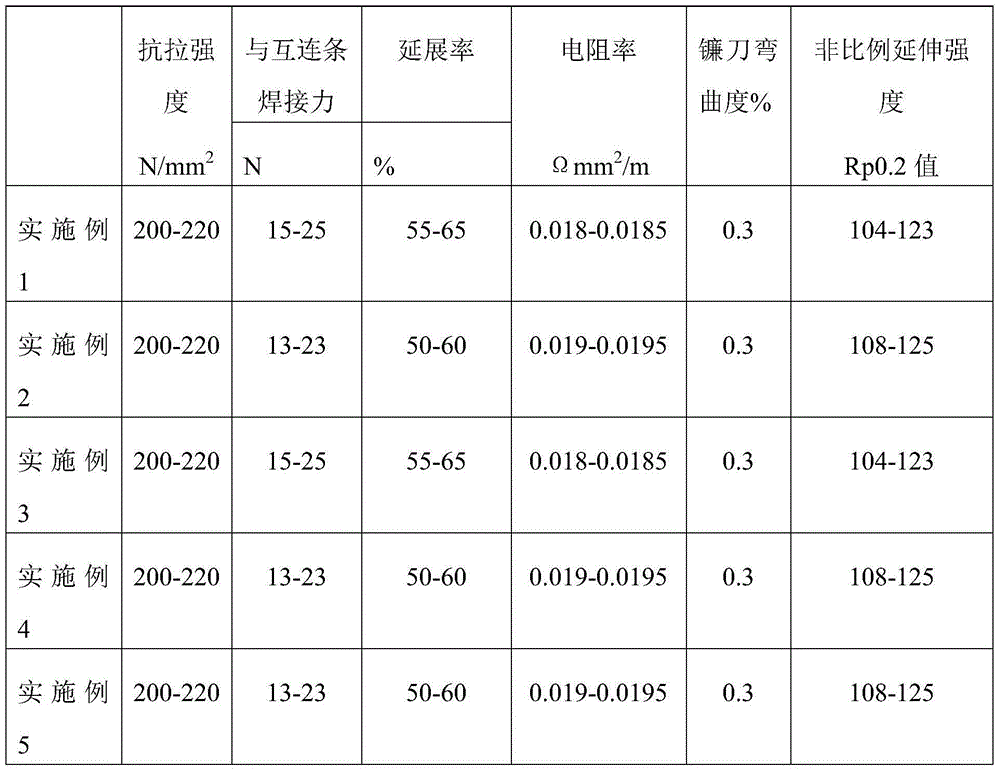

Examples

Embodiment 1

[0031] The solder used on the busbar of the solar cell module in this embodiment is composed of the following components by weight: tin: 62wt%, bismuth: 1.0wt%, antimony: 2.0wt%, gallium: 0.03wt%, indium: 1.5 wt%, germanium: 1wt%, titanium: 0.1wt%, nickel: 0.5wt%, palladium: 0.005wt%, and the balance is lead.

[0032] The method for preparing the above-mentioned solder on the busbar of a solar cell module is as follows:

[0033] Pre-treatment: Remove oil stains and oxides on the surface of the substrate by alkali washing and acid washing;

[0034] Hot dip plating: the substrate is immersed in the molten metal solution configured by weight percentage, and the hot dip plating temperature is 240 degrees Celsius to form a coating;

[0035] Post-treatment: surface chemical treatment, tape-making, cutting and reeling.

Embodiment 2

[0037] The solder used on the busbar of the solar cell module in this embodiment is composed of the following components by weight: tin: 64wt%, bismuth: 0.01wt%, antimony: 0.01wt%, gallium: 0.015wt%, indium: 0.05 wt%, germanium: 0.005wt%, titanium: 0.005wt%, nickel: 0.05wt%, palladium: 0.1wt%, and the balance is lead.

[0038] The method for preparing the above-mentioned solder on the busbar of a solar cell module is as follows:

[0039] Pre-treatment: Remove oil stains and oxides on the surface of the substrate by alkali washing and acid washing;

[0040] Hot dip plating: the substrate is immersed in the molten metal solution configured by weight percentage, and the hot dip plating temperature is 300 degrees Celsius to form a coating;

[0041] Post-treatment: surface chemical treatment, tape-making, cutting and reeling.

Embodiment 3

[0043] The solder used on the busbar of the solar cell module in this embodiment is composed of the following components by weight: tin: 62.5wt%, bismuth: 0.5wt%, antimony: 1.0wt%, gallium: 0.025wt%, indium: 1.5wt%, germanium: 0.5wt%, titanium: 0.05wt%, nickel: 0.5wt%, palladium: 0.005wt%, and the balance is lead.

[0044] The method for preparing the above-mentioned solder on the busbar of a solar cell module is as follows:

[0045] Pre-treatment: Remove oil stains and oxides on the surface of the substrate by alkali washing and acid washing;

[0046] Hot dip plating: the substrate is immersed in the molten metal solution configured by weight percentage, and the hot dip plating temperature is 260 degrees Celsius to form a coating;

[0047] Post-treatment: surface chemical treatment, tape-making, cutting and reeling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com