Weather-resistant UV curing coating

A technology for curing coatings and weather resistance, applied in the field of coatings, can solve the problems of poor weather resistance of UV coatings, residual photosensitizer fragments, easy to fall off, etc., and achieve the effects of good weather resistance, fast curing and drying, and high surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

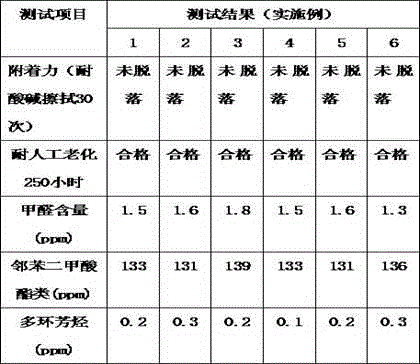

Examples

Embodiment 1

[0019] The weather-resistant UV curable coating of the present invention comprises the following components in parts by weight: 35 parts of aminoacrylic resin, 10 parts of polyethylene wax, 5 parts of ethyl acetate, 2 parts of propylene glycol methyl ether acetate, 1 part of dimethyl carbonate 9 parts, 9 parts of rare earth luminous powder, 2 parts of methyl cellulose, 10 parts of polydimethylsiloxane, 2 parts of polyoxyethylene alkylphenol ether, 20 parts of ethylene glycol.

Embodiment 2

[0021] The weather-resistant UV curable coating of the present invention comprises the following components in parts by weight: 25 parts of epoxy acrylic resin, 20 parts of polyethylene wax, 15 parts of ethyl acetate, 8 parts of propylene glycol methyl ether acetate, dimethyl carbonate 5 parts, 3 parts of rare earth luminescent powder, 7 parts of hydroxypropyl methylcellulose, 1 part of alkyl modified organosiloxane, 6 parts of polyoxyethylene fatty alcohol ether, 30 parts of ethyl acetate.

Embodiment 3

[0023] The weather-resistant UV curing coating of the present invention comprises the following components in parts by weight: 30 parts of aminoacrylic resin, 30 parts of epoxy acrylic resin, 15 parts of polyethylene wax, 10 parts of ethyl acetate, 5 parts of propylene glycol methyl ether acetate, 3 parts of dimethyl carbonate, 6 parts of rare earth luminescent powder, 4 parts of sodium carboxymethyl cellulose, 6 parts of polyether polyester modified organosiloxane, 4 parts of sulfonate, 25 parts of butyl acetate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com