Measuring method of calcium content in silicon-calcium wire

A determination method and technology of calcium content, which can be used in material excitation analysis, fluorescence/phosphorescence, etc., can solve the problems of cumbersome and time-consuming operation, and achieve the effect of shortening the operation process, saving drugs, and stable measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The above-mentioned and other technical features and advantages of the present invention will be described in more detail below in conjunction with the embodiments.

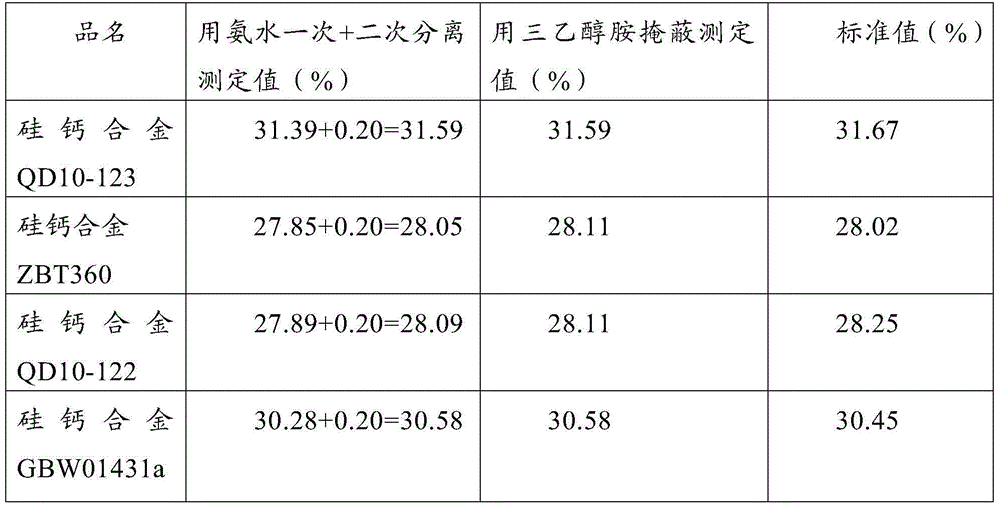

[0022] 1. Method summary: Dissolve the silicon-calcium wire sample in a polyethylene plastic beaker with nitric acid (67%)-hydrofluoric acid (40%), add 5mL perchloric acid (70%) to smoke, smoke off, and test solution After drying, after cooling, carefully add 10mL hydrochloric acid (65%) along the wall of the cup, and heat to dissolve the salts. Transfer the test solution to a 250mL volumetric flask, dilute to the scale constant volume, divide 50mL of the solution into a 250mL beaker, add 50mL of triethanolamine (12%), add 50mL of water, add a little hydroxylamine hydrochloride (the purpose of adding hydroxylamine hydrochloride, the same To play a further masking effect, the amount of addition is generally about 0.5 grams.), add 30mL potassium hydroxide solution (20%) (as a buffer solution, the complexatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com