Method for measuring content of phosphorus in sintered flux

A technology for sintering flux and measuring method, applied in material excitation analysis, thermal excitation analysis and other directions, can solve the problem of difficult phosphorus content, improve accuracy and precision, avoid working curve drift and low result system, solve The effect of long-term low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) The sintered flux used by Baoji Yusheng Flux Factory was used as sample 1#.

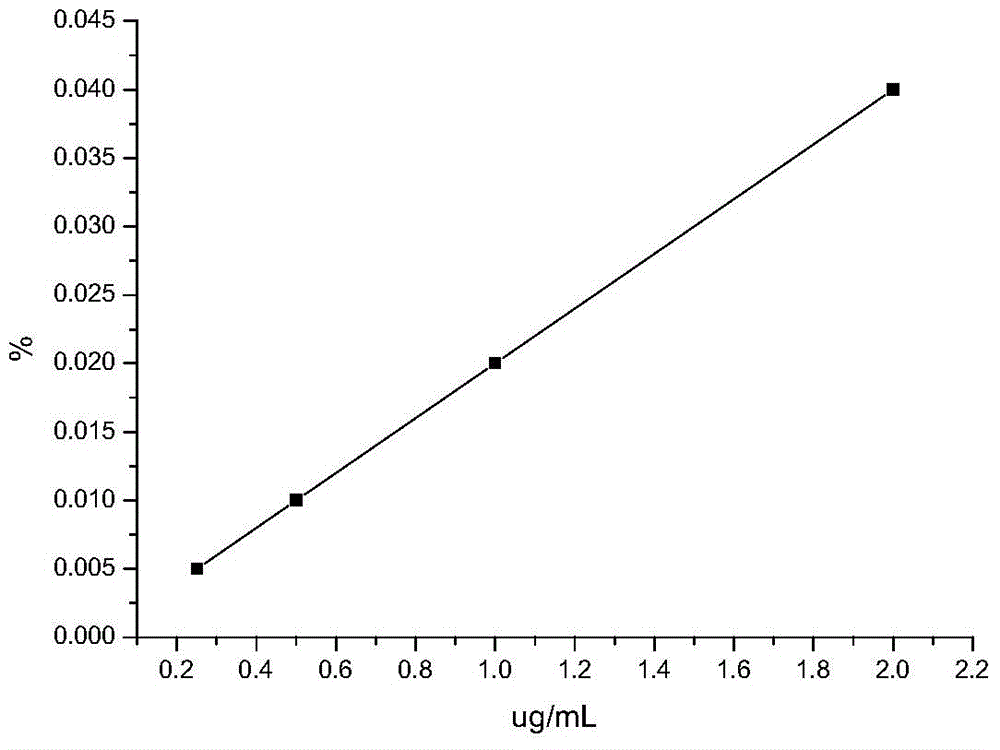

[0029] 2) Weigh 0.5000g of sample 1#, place it in a 300mL polytetrafluoroethylene beaker, moisten it with a small amount of water, add nitric acid and hydrofluoric acid, heat at low temperature for 20 minutes, add hydrochloric acid, and continue heating for 30 minutes. The volume ratio of nitric acid, hydrofluoric acid, and hydrochloric acid is 1:1:4, add 5mL perchloric acid, heat at low temperature until perchloric acid fumes, and continue heating until the volume is about 2mL. Continue to add 5mL of perchloric acid, heat at low temperature and smoke perchloric acid until nearly dry. Cool slightly, add 10mL hydrochloric acid (1+9), rinse the wall of the cup with a small amount of water, heat for 5min to dissolve the salt, remove it, and cool to room temperature. Filter with slow filter paper with a small amount of pulp, rinse the beaker and precipitate with hot water for 5-6 times, and ke...

Embodiment 2

[0034]1) Use the sintered flux used by Luoyang Peony Flux Factory as sample 2#.

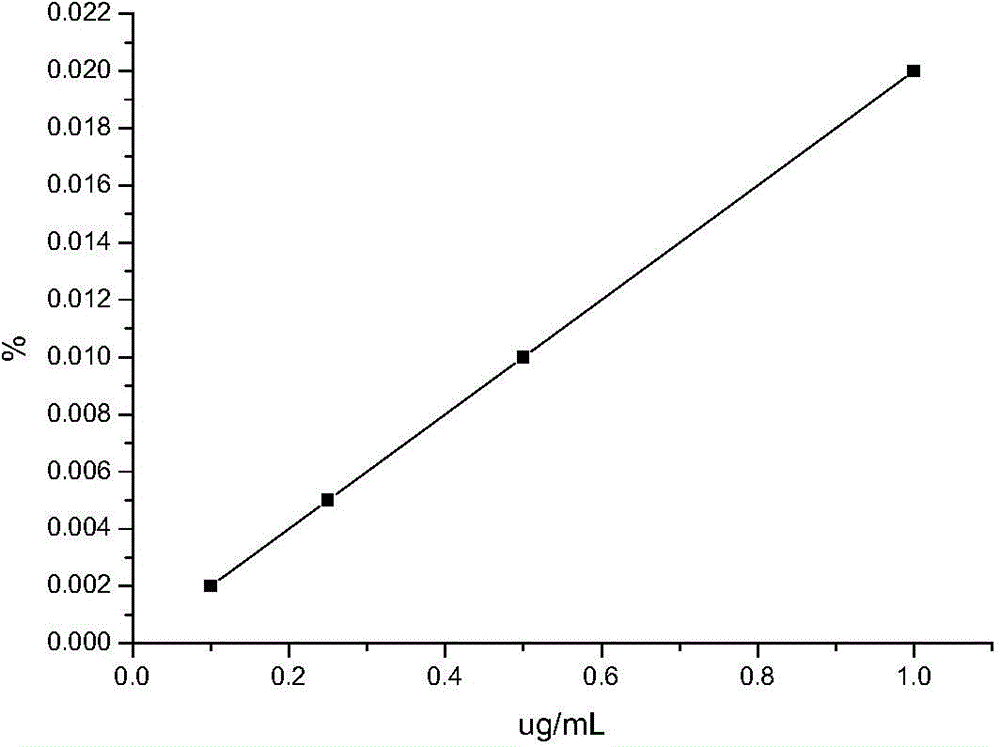

[0035] 2) Weigh 1.0000g of sample 2#, place it in a 300mL polytetrafluoroethylene beaker, moisten it with a small amount of water, add nitric acid and hydrofluoric acid, heat at low temperature for 20 minutes, add hydrochloric acid, and continue heating for 30 minutes. The volume ratio of nitric acid, hydrofluoric acid, and hydrochloric acid is 1:1:6, add 5mL perchloric acid, heat at low temperature until perchloric acid fumes, and continue heating until the volume is about 2mL. Continue to add 8mL of perchloric acid, heat at low temperature and smoke perchloric acid until nearly dry. Cool slightly, add 15mL hydrochloric acid (1+9), rinse the wall of the cup with a small amount of water, heat for 5min to dissolve the salt, remove it, and cool to room temperature. Filter with slow filter paper with a small amount of pulp, rinse the beaker and precipitate with hot water for 5-6 times, and keep the...

Embodiment 3

[0040] 1) The sintered flux used by Wuhan Iron Anchor is used as sample 3#.

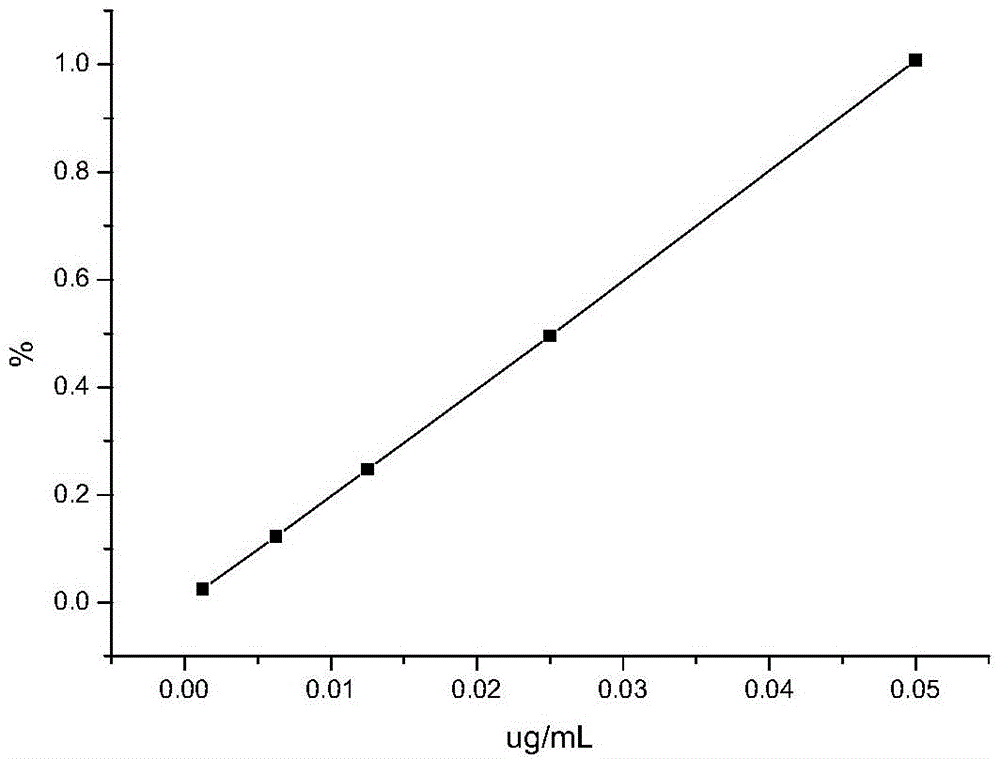

[0041] 2) Weigh 0.8000g of sample 3#, place it in a 300mL polytetrafluoroethylene beaker, moisten it with a small amount of water, add nitric acid and hydrofluoric acid, heat at low temperature for 20 minutes, add hydrochloric acid, and continue heating for 30 minutes. The volume ratio of nitric acid, hydrofluoric acid, and hydrochloric acid is 1:1:5, add 8mL perchloric acid, heat at low temperature until perchloric acid fumes, and continue heating until the volume is about 2mL. Continue to add 3mL of perchloric acid, heat at low temperature and smoke perchloric acid until it is almost dry. Cool slightly, add 12mL of hydrochloric acid (1+9), rinse the wall of the cup with a small amount of water, heat for 5min to dissolve the salt, remove it, and cool to room temperature. Filter with slow filter paper with a small amount of pulp, rinse the beaker and precipitate with hot water for 5-6 times, and kee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com