A kind of method and system for preparing polyferric chloride sulfate with pickling waste liquid

A technology for polymerizing chlorinated sulfuric acid and pickling waste liquid, applied in ferric sulfate, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of environmental pollution and high cost, shorten the reaction time, reduce the production cost, and increase the gas Effect of liquid mixing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

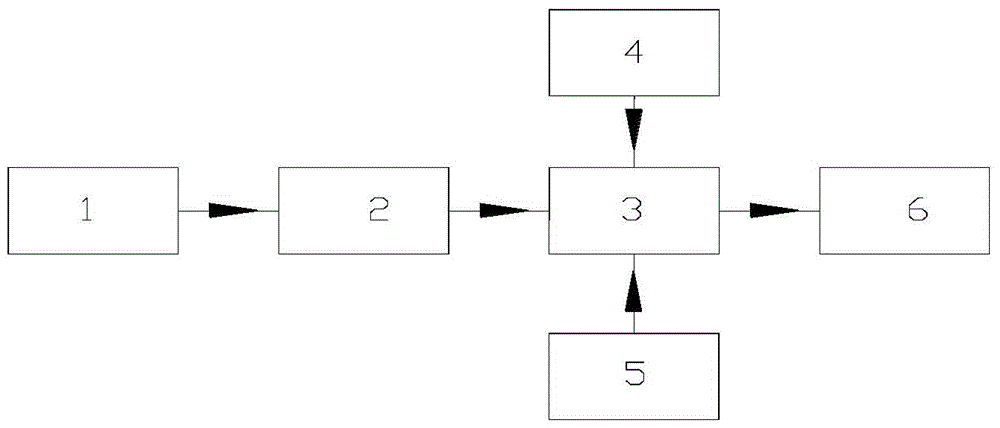

Image

Examples

Embodiment 1

[0036] Adding total iron content in the dissolving tank under agitation is 20kg of pickling waste liquid 20kg, ferrous sulfate 3.4kg, concentrated hydrochloric acid 2kg of 9 (w / w)% in the dissolving kettle, treats that after ferrous sulfate dissolves, add pickling waste liquid weight 0.3(w / w)% stabilizer trisodium phosphate, stir well and evenly. Heat the solution to 70°C, pump it into the circulating reactor. The external circulation of the circulating reactor is opened, and oxygen is introduced. The prepared sodium nitrate and potassium iodide solutions with a total concentration of 11.2 (w / w)% were continuously added to the circulating reactor, and the addition was completed within 1 hour. The reaction was carried out for 2.5 hours, and the polymerized ferric sulfate chloride was obtained after aging for 18 hours.

[0037] Take 0.85mL of polyferric sulfate chloride product, put it into 1L of domestic wastewater, stir it mechanically for 8 minutes, let it stand for stratif...

Embodiment 2

[0041] Adding total iron content to the dissolving tank under stirring conditions is 60kg of pickling waste liquid, 4kg of iron powder, and 6kg of concentrated sulfuric acid with a total iron content of 11 (w / w). After the iron powder dissolves, add 0.2 (w) / w)% stabilizer sodium dihydrogen phosphate, fully stir evenly. Heat the solution to 80°C and pump it into the circulating reactor. The external circulation of the reactor was opened, and oxygen was introduced. The prepared sodium nitrate and potassium iodide solutions with a total concentration of 13.6 (w / w)% are continuously added to the circulating reactor, and the addition is completed within two hours. The reaction was carried out for 3 hours, and the polymerized ferric sulfate chloride was obtained after aging for 16 hours.

[0042] Put 0.6mL of polyferric chloride product into 1L of synthetic wastewater, stir it mechanically for 11 minutes, let it stand for stratification, take the upper liquid to measure the chemi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com