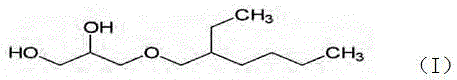

Method for preparing high-purity ethylhexylglycerin

An ethylhexylglycerol, high-purity technology, applied in ether preparation, organic chemistry and other directions, can solve the problems of long reaction time, easy oxidation and discoloration, difficult separation and purification, etc., to reduce energy consumption and raw material costs, and facilitate large-scale production. , the effect of a good preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In a 2000 ml four-neck flask equipped with a mechanical stirrer, a thermometer, and a dropping funnel, add 330 g of 2-ethylhexyl glycidyl ether, place the flask in a water bath, and control the temperature at 10 to 20°C while stirring. Add 175 grams of acetone and 10 grams of catalyst dropwise, and the time for dropping is 40 minutes. After keeping for 120 minutes, add 15 grams of methylamine aqueous solution and keep for 10 minutes to distill the remaining acetone under reduced pressure, and add 40 grams of formic acid to the remaining reactants. 50 grams of distilled water, heated in a water bath at 50-55 ° C for 180 minutes, let stand to separate the liquid, neutralized the oil phase with sodium bicarbonate to neutral, washed twice with water, added a stabilizer, and then carried out short-path distillation, the vacuum degree was controlled at 40 ~50Pa, collect the distillate with distillation temperature in the range of 135~145°C to obtain the high-purity ethylhexylg...

Embodiment 2

[0034] Replace the methylamine aqueous solution in example 1 with 20 grams of ammoniacal liquor, and it is with embodiment 1 with step, obtains high-purity ethylhexylglycerin of the present invention, through gas chromatography analysis, purity 99.5%, yield 89.0%, colorless and tasteless.

Embodiment 3

[0036] Compared with Example 1, no terminator is added.

[0037] In a 2000 ml four-neck flask equipped with a mechanical stirrer, a thermometer, and a dropping funnel, add 330 grams of 2-ethylhexyl glycidyl ether, and place the flask in a water bath. Under stirring, the temperature is controlled at 10-20°C, and 175 grams of acetone and 15 grams of boron trifluoride ether catalyst are added dropwise at the same time. The dropwise addition time is 40 minutes. The reaction solution is brown, and the subsequent steps are the same as in Example 1. Analysis, purity 48.3%, yield 56%, color and luster is light brown, and smell is big, can not be used as the additive of daily chemical product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com