Production method of clenbuterol molecularly imprinted-upconversion luminescent material fluorescence probe

A technology of luminescent materials and molecular imprinting, which can be used in cross-cutting fields and can solve the problems of life-threatening, long residual time, toxic and side effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

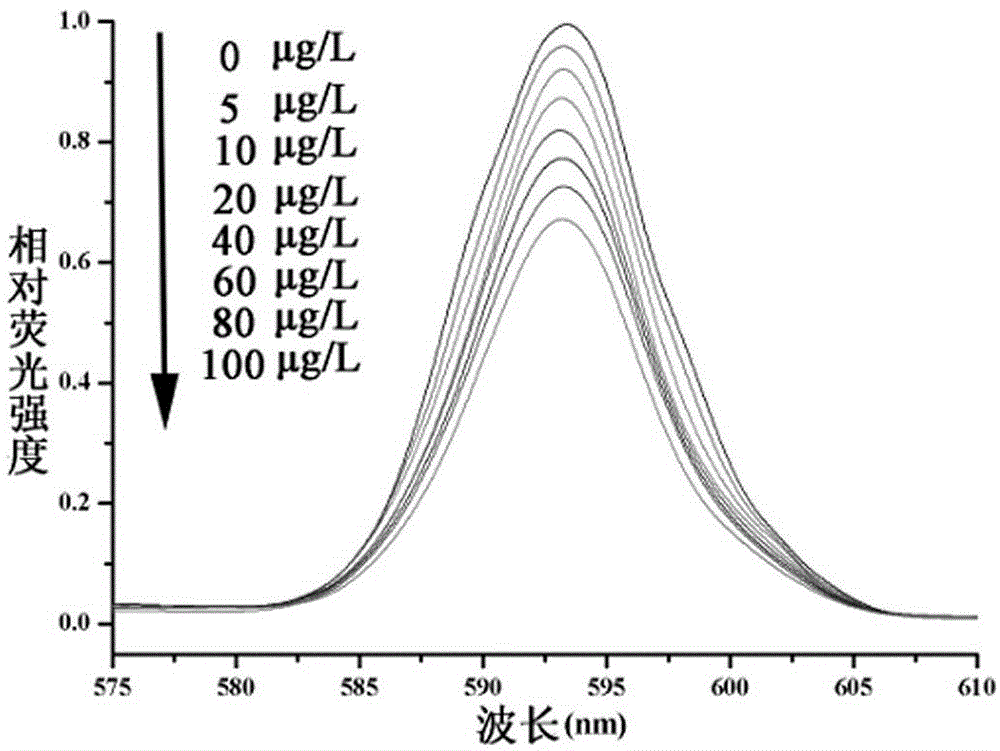

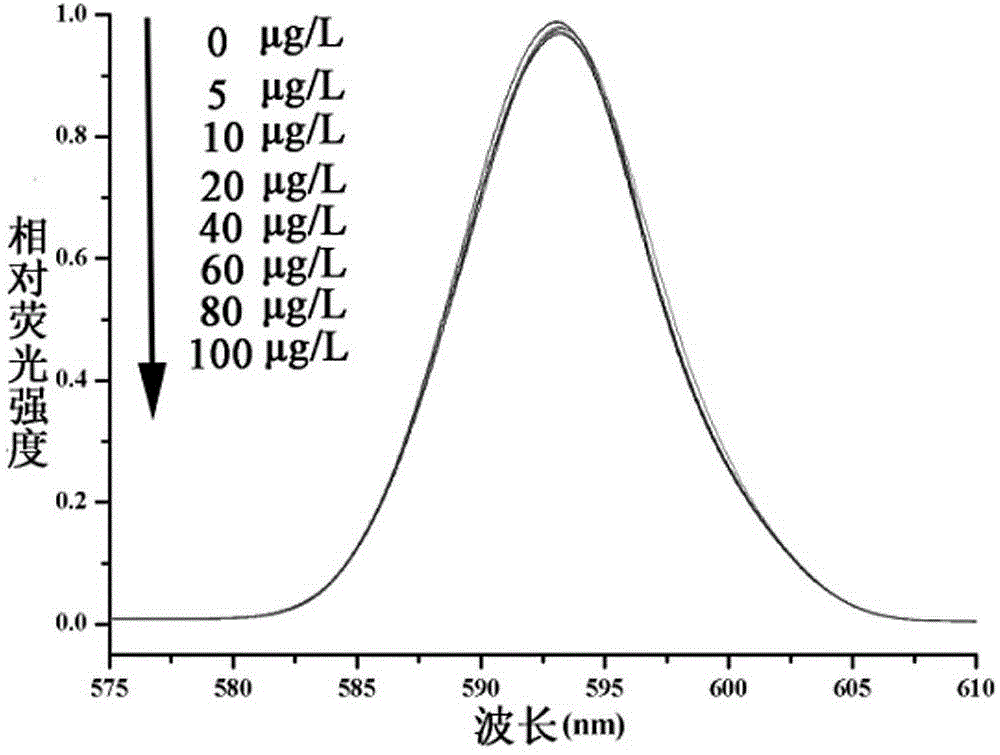

[0032] The invention relates to a clenbuterol molecular imprinting-up-conversion luminescent material-labeled fluorescent probe preparation method, which is characterized in that: the up-conversion luminescent material YF 3 :Yb 3+ ,Er 3+ As a carrier, a fluorescent probe formed by covalently preparing clenbuterol molecularly imprinted polymers, this fluorescent probe combines the high selectivity of molecularly imprinted polymers and the special fluorescence emission characteristics of up-conversion luminescent materials. The preparation steps are as follows:

[0033] (1) Set Y(NO 3 ) 3 , Yb(NO 3 ) 3 , Er(NO 3 ) 3 Mix with distilled water, stir until completely dissolved, add EDTA and NaF solution, continue stirring for 5-10 minutes, transfer the above mixture solution to a hydrothermal reaction kettle, and use NaOH or HNO 3 Solution Adjust the pH value of the solution to 3, then tighten the hydrothermal reactor and place it under the condition of 180°C for hydrotherma...

Embodiment 1

[0048] A clenbuterol molecular imprinting-up-conversion luminescent material fluorescent probe preparation method is the up-conversion luminescent material YF 3 :Yb 3+ ,Er 3+ As a carrier, combined with the fluorescent probe formed by clenbuterol molecular imprinting prepared by the covalent bond method, the steps are as follows:

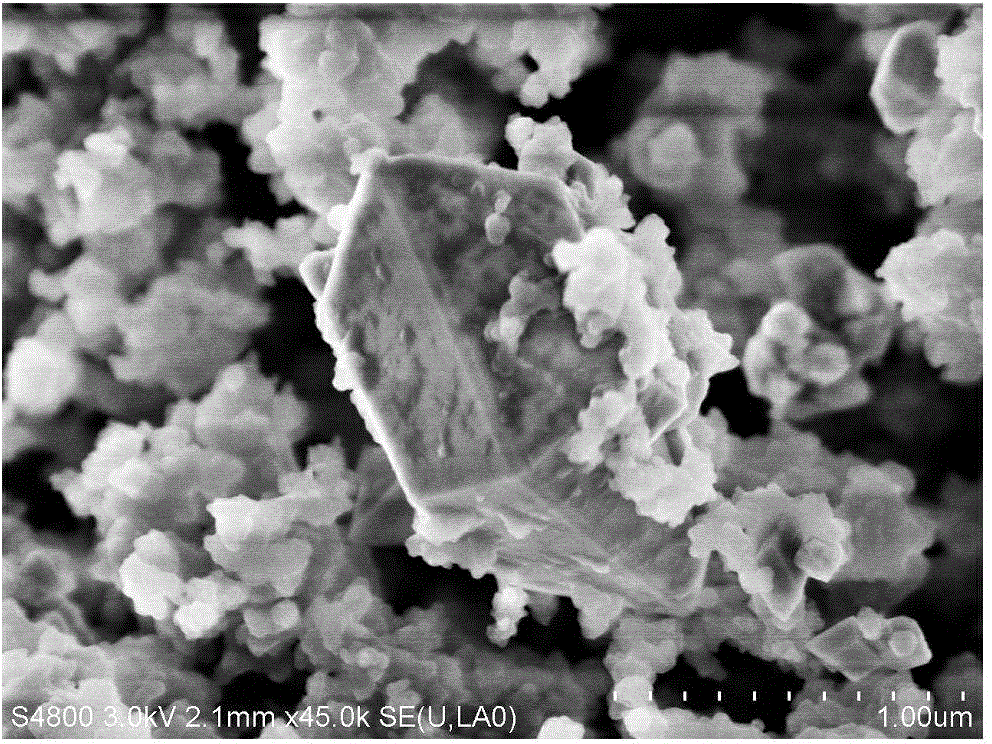

[0049] (1) Preparation of up-conversion luminescent materials:

[0050] 6.6 mmol Y(NO 3)3 (purity 99.99%), 1.69 mmol Yb(NO 3 ) 3 (purity 99.99%), 0.169 mmol Er(NO 3 ) 3 (purity 99.99%) mixed with 13.0~18.0 mL distilled water, stirred until completely dissolved, then added 33.0 mL EDTA (6.6 mmol) solution and 33.0 mL NaF (46 mmol) solution, continued stirring for 5~10 minutes, then transferred the above mixture solution To the hydrothermal reactor, use NaOH or HNO 3 Solution Adjust the pH value of the solution to 3, then tighten the hydrothermal reactor and place it under the condition of 180°C for hydrothermal reaction for 24 hours to obtain...

Embodiment 2

[0058] A clenbuterol molecular imprinting-upconversion luminescent material fluorescent probe preparation method, in step (2), mix 200 mL of 3 mol / L sodium hydroxide solution with 5 g of fluorescent probe, heat and reflux for 48 hours; prepare Clenbuterol For terol derivatives, dissolve 10 mmol of clenbuterol in 55 mL of dichloromethane, add 35 mmol of triethylamine to the solution, drop 25 mmol of methacryloyl chloride, and react overnight at room temperature; other conditions are the same as in the examples 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com