Unwinding method and unwinding tank capable of preserving tussah cocoon shell sericin

A technology of cocoon shells and tussah silkworms, which is applied in the chemical post-treatment of fibers, textiles and papermaking, and fiber treatment. It can solve the problems of high energy consumption in high-temperature operation of unwinding equipment and difficulties in unwinding control, achieving large investment and reliable environment. The effect of low temperature control and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

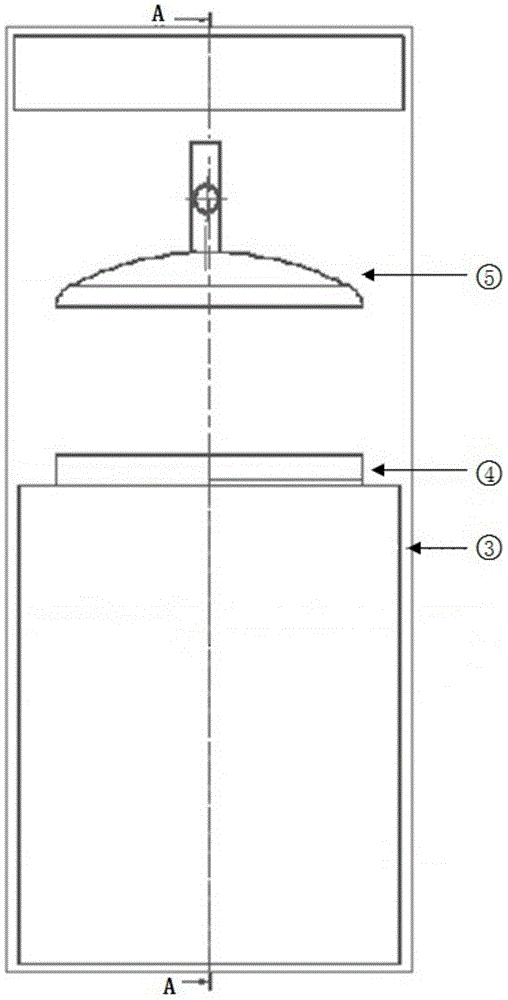

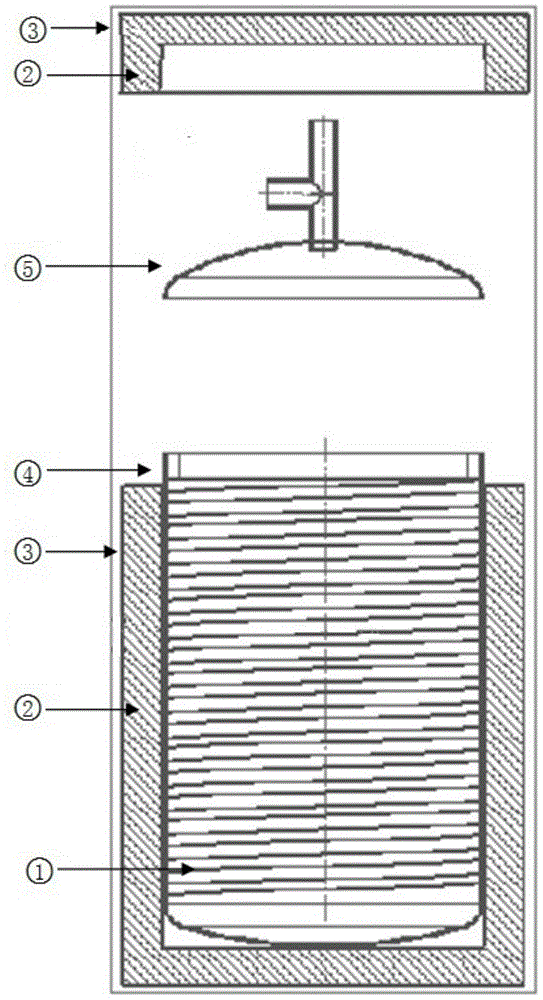

[0064] The relief tank includes a tank body 4 and an upper cover 5; an insulation layer is provided on the outside of the tank body 4 and the upper cover 5, and the insulation layer is sequentially formed from polystyrene foam 2 and glass fiber reinforced plastic fiber 3 into one body through resin curing from the inside to the outside. ; The inner wall of the tank body 4 is evenly laid with heating wires; the heating wires are corrosion-resistant polytetrafluoroethylene electric heating wires.

[0065]10 kilograms of tussah silkworm incision cocoon shells are packed into a nylon mesh bag, placed in a tank body 4 with a volume of 400 liters, and injected with a relaxing solution (the relaxing solution is composed of ammonia, urea, ethylenediaminetetraacetic acid and water, the mass concentration of ammonia 8%, the mass concentration of urea is 0.5%, the mass concentration of ethylenediaminetetraacetic acid is 2%), after being heated to 50 ℃, stop heating and keep warm for 30 ho...

Embodiment 2

[0067] 10 kilograms of tussah silkworm moth mouth cocoon shells are packed into a nylon mesh bag, placed in the tank body 4 of Example 1 with a volume of 400 liters, and injected with a relaxing solution (the relaxing solution is composed of ammonia, urea, ethylenediaminetetraacetic acid and water, The mass concentration of ammonia water is 5%, the mass concentration of urea is 0.1%, the mass concentration of ethylenediaminetetraacetic acid is 1.5%), stop heating after being heated to 55 ℃, keep warm for 24 hours, tussah moth mouth cocoon shell is loosened completely. The tussah silkworm cocoon shell in the tank completes the swelling of the cocoon layer and fully opens the joints of the thread glue while preserving the sericin. The sericin is undamaged after unwinding, and the pigment, wax, calcium oxalate, and metal ions are completely dissolved, and the cocoon shell is loose. The relief solution is collected, which can be reused and eventually collected as organic fertilizer...

Embodiment 3

[0069] The relief fluids of Embodiment Example 1 and Embodiment Example 2 are collected and used as relief fluids.

[0070] 10 kilograms of tussah silkworm cut cocoon shells are packed into a nylon mesh bag, placed in the tank body 4 of Example 1 with a volume of 400 liters, and injected with a relaxing solution (this solution is the relaxing solution collected in Example 1 or Example 2) ), stop heating after heating to 60°C, keep warm for 20 hours, and the tussah silkworm's cut cocoon shell will be completely relieved. The tussah silkworm cocoon shell in the tank completes the swelling of the cocoon layer and fully opens the joints of the thread glue while preserving the sericin. The sericin is undamaged after unwinding, and the pigment, wax, calcium oxalate, and metal ions are completely dissolved, and the cocoon shell is loose. The relief solution is collected, which can be reused and eventually collected as organic fertilizer. So as to achieve the whole process of environ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com