A kind of shear piezoelectric composite material

A piezoelectric composite material, shear type technology, applied in the direction of material selection for piezoelectric devices or electrostrictive devices, device material selection, etc., can solve problems such as endangering personnel safety, high polarization voltage, hidden dangers, etc. Achieving the effects of wide adjustment range, reduced polarization voltage, and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

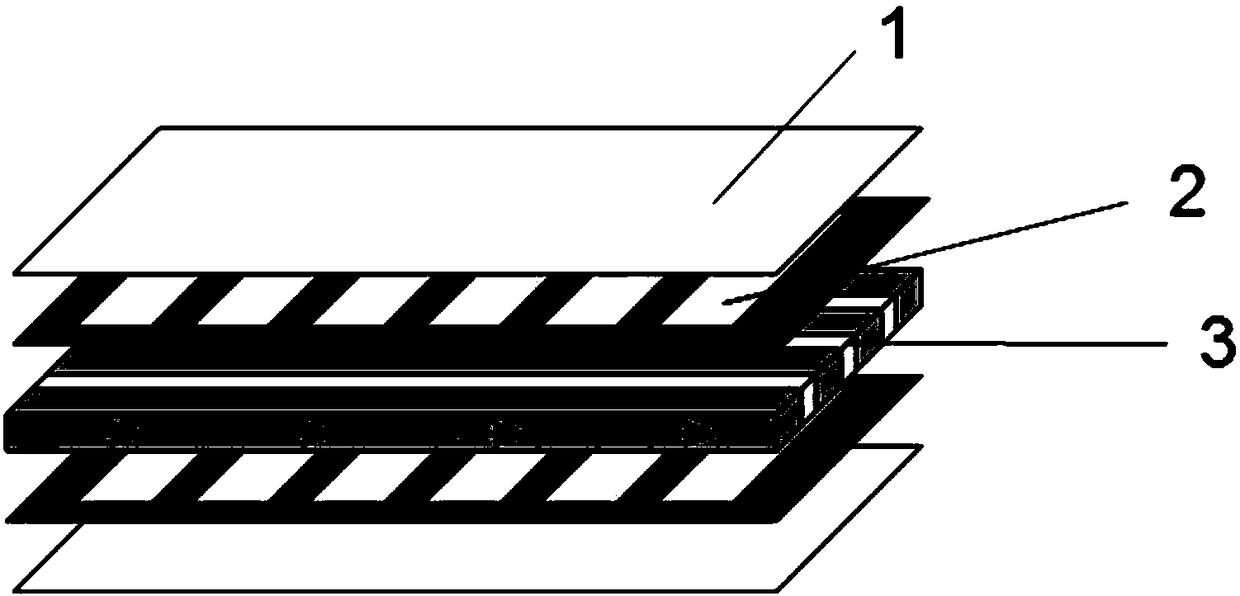

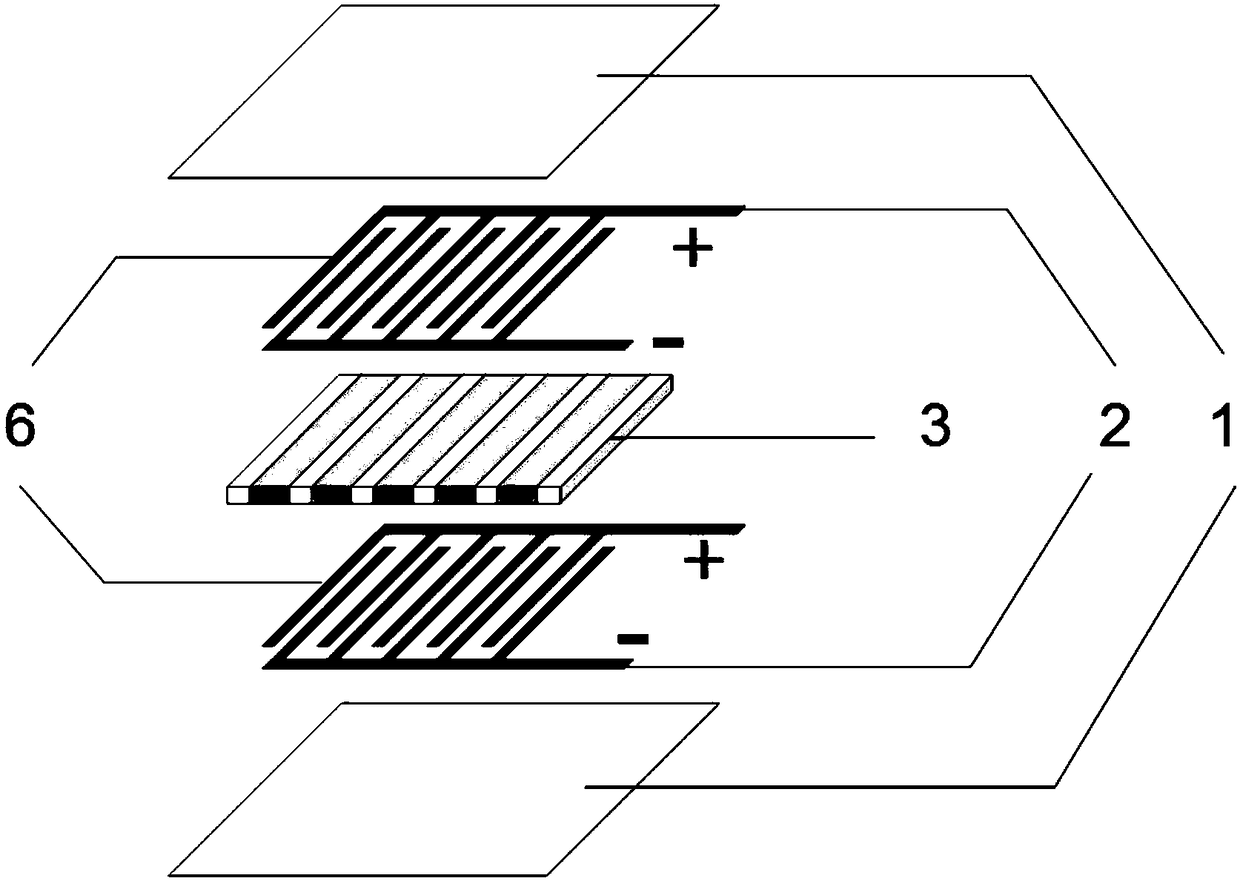

Embodiment 1

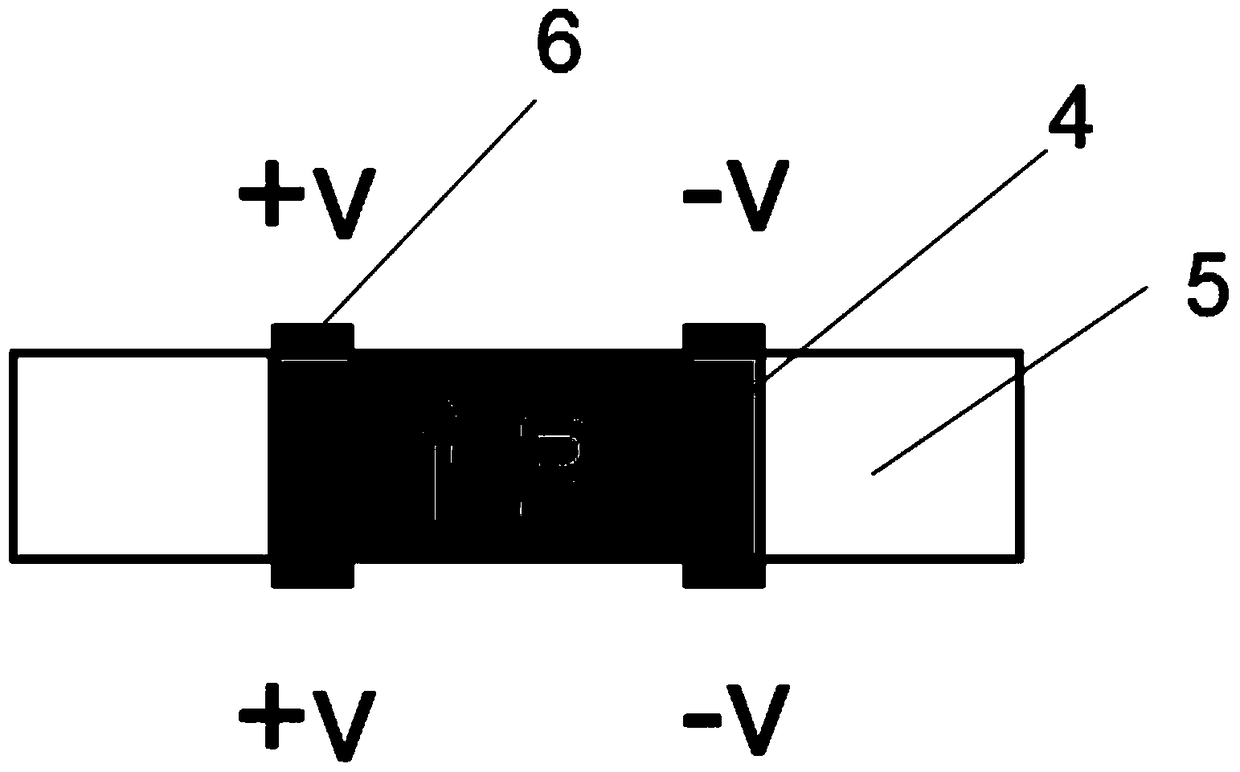

[0034] The lead zirconate titanate piezoelectric ceramics are processed into slices of 30mm×10mm×0.5mm. After washing and drying, silver paste is applied on the upper and lower surfaces to make electrodes, and a polarization voltage of 1.5kV is applied to obtain 3kV / mm in the thickness direction. The polarizing electric field makes it polarized along the thickness direction. It is cut by a cutting machine, and a piezoelectric ceramic fiber array with fiber width and fiber spacing equal to 0.5 mm is obtained by selecting blades of appropriate thickness and setting the cutting distance. Fill the array with E-51 epoxy resin, and after curing, obtain a 30mm×10mm×0.18mm lead zirconate titanate / E-51 epoxy resin composite layer 3 through thinning treatment. In this process, the upper and lower surfaces of the original piezoelectric ceramics The coated silver paste electrode has been worn away. The interdigital electrodes were printed on the polyimide film by screen printing. The dist...

Embodiment 2

[0036] The pre-fired lead zirconate titanate powder and carbon black powder are mixed with the binder, plasticizer, dispersant and solvent, respectively, and made into sheet-shaped green bodies by the casting method. After alternate stacking, they are pressed, decarburized and combined. After sintering, a matrix of lead zirconate titanate sheets is formed. Fill the matrix with 711 epoxy resin, and cut to obtain a lead zirconate titanate / E-51 epoxy resin composite layer after curing. In the above process, by controlling the green thickness, cutting distance and other parameters, the size of the lead zirconate titanate / E-51 epoxy resin composite layer finally obtained is 10mm×5mm×0.2mm, and the fiber width and fiber spacing are both 0.4mm. The interdigital electrodes are printed on the upper and lower sides of the lead zirconate titanate / 711 epoxy resin composite layer by screen printing. The distance between the positive and negative fingers of the interdigital electrode is 0.4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com