Agricultural composition containing naphthylacetic acid and strobilurin fungicide

A methoxyacrylic acid and fungicide technology, which is applied in the direction of fungicides, biocides, biocides, etc., can solve the problems of no mixed reports of naphthalene acetic acid fungicides, slow wound healing, easy re-infection of pathogenic bacteria, etc. , to achieve the effect of improving wound healing effect, promoting healing and reducing the frequency of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

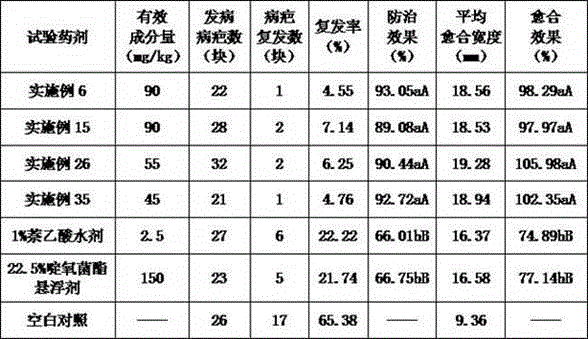

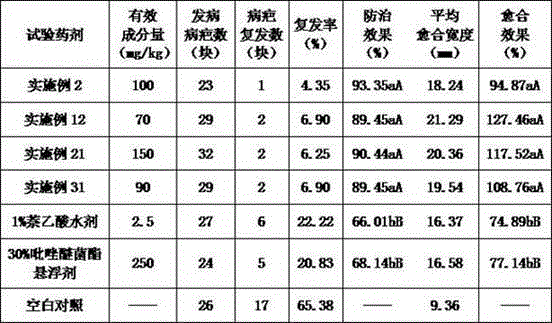

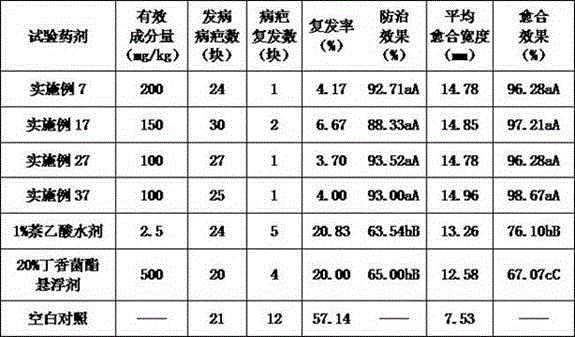

Examples

Embodiment 1

[0030] Weigh 0.25% naphthalene acetic acid, 25% pyraclostrobin, 3% polycarboxylate, 3% polyoxyethylene polyoxypropylene ether block copolymer, 1% magnesium aluminum silicate, 0.2% xanthan gum, 5% ethylene glycol, 0.1% formaldehyde, 0.3% silicone defoamer (trade name: s-29 produced by Nanjing Sixin Applied Chemicals Company), and deionized water to 100% by weight. The above raw materials are mixed, dispersed at high speed for 30 minutes, and sanded with a sand mill to a particle size of D 90 25.25% naphthaleneacetic acid pyraclostrobin suspension concentrate was prepared after the thickness was less than 10 μm.

Embodiment 2

[0032] Weigh 0.2% naphthalene acetic acid, 17% pyraclostrobin, 3% polyoxyethylene polyoxypropylene ether block copolymer, 1.5% fatty alcohol polyoxyethylene ether phosphate, 2% sodium alkylnaphthalene sulfonate, 1% magnesium aluminum silicate, 0.4% bentonite, 5% glycerin, 0.1% benzoic acid, 0.3% silicone defoamer (trade name: s-29 produced by Nanjing Sixin Applied Chemicals Company), deionized water to 100 % parts by weight. The above raw materials are mixed, dispersed at high speed for 30 minutes, and sanded with a sand mill to a particle size of D 90 A 17.2% naphthaleneacetic acid pyraclostrobin suspension concentrate was prepared after the thickness was less than 10 μm.

Embodiment 3

[0034] Weigh 0.1% naphthaleneacetic acid, 10% trifloxystrobin, 4% alkyl polyoxyethylene ether sulfonate, 3% triphenylethylphenol polyoxypropylene polyoxyethylene block polymer, 0.2% bentonite, 5% propylene glycol , 0.2% benzoic acid, 0.5% octanol, deionized water added to 100% by weight. The above raw materials are mixed, dispersed at high speed for 30 minutes, and sanded with a sand mill to a particle size of D 90 A 10.1% naphthaleneacetic acid trifloxystrobin suspension concentrate was prepared after the thickness was less than 10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com