Catalyst of hydrogenation synthesis of ethylene glycol from dimethyl oxalate and preparation method of the catalyst

A technology of dimethyl oxalate and catalyst, which is applied in the field of selective hydrogenation catalyst and its preparation, can solve the problems that the life of the catalyst cannot meet the requirements of industrialization, the catalyst reaction temperature and pressure are high, and the heat and power consumption are high, so as to achieve long life and selectivity High performance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

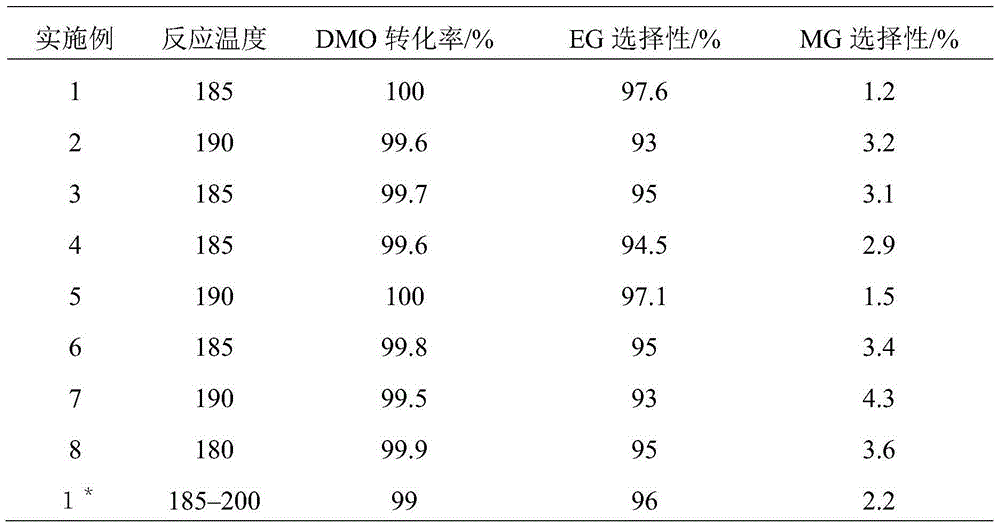

Examples

Embodiment 1

[0020] A kind of synthetic method of the catalyst that prepares ethylene glycol by hydrogenation of dimethyl oxalate: its steps are as follows:

[0021] (1) 13.4g copper nitrate, 0.05g neodymium nitrate are dissolved in 43g distilled water respectively, obtain mixed salt solution;

[0022] (2) Add 100 g of ethanol and 70 g of tetraethyl orthosilicate to the mixed salt solution obtained in step (1), mechanically stir the mixed solution and place it in a water bath at 70° C. for 1–2 hours to form a sol-gel; After the gel was aged at room temperature for 24 hours, it was dried in an oven with programmed temperature, at 70°C for 17 hours, then at 90°C for 40 hours, and finally at 120°C for 4 hours;

[0023] (3) The catalyst precursor prepared in step (2) is crushed and screened with a stainless steel sieve for 10-20 mesh;

[0024] (4) preparing 200ml of pH in a beaker is 11 aqueous ammonia solution, then the catalyst precursor screened by step (3) is added in the beaker;

[0025...

Embodiment 2

[0030] Catalyst preparation is the same as in Example 1, except that 0.05g of neodymium nitrate is changed to 0.3g of neodymium nitrate in step (1). Above operation obtains catalyzer, and the content of metal copper in this catalyzer is 13.1% through ICP measurement, and the content of auxiliary agent neodymium is 0.95%, and the specific surface (m) of catalyzer is measured through BET 2 / g) is 453, the pore volume (cm 3 / g) was 0.60.

Embodiment 3

[0032] Catalyst preparation is the same as in Example 1, except that 0.05g of neodymium nitrate is changed to 0.05g of lanthanum nitrate in step (1). Above operation obtains catalyzer, and the content of metal copper in this catalyzer is measured through ICP and is 14.6%, and the content of auxiliary agent lanthanum is 0.12%, and the specific surface (m 2 / g) is 515, the pore volume (cm 3 / g) was 0.81.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com