Trelagliptin purification method

A purification method and mixed solvent technology, applied in organic chemistry and other directions, can solve the problems of low purity, low yield, solvates, etc., and achieve the effect of improving purification yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

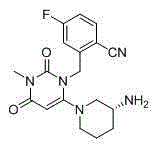

[0018] Example 1 Preparation of Crude Trexagliptin

[0019] Add 93g of 2-(6-chloro-3-methyl-2,4-dioxo-3,4-dihydro-2H-pyrimidin-1-ylmethyl)-4-fluoro-benzonitrile into a 10L three-necked flask , RAPD 60.3g, acetonitrile 372mL, lower the temperature below 10°C, and add DBU 212g dropwise. After the addition, the temperature was raised to 10-20°C, and the reaction was kept for 3 hours. Add ice water and dichloromethane, adjust pH=1-4 with 4M hydrochloric acid, separate liquid, wash water phase with DCM; combine water phase, add DCM, adjust pH=8-10 with saturated potassium carbonate solution, separate liquid, water phase Extract with DCM, combine the organic phases, dry, filter and concentrate to obtain 99 g of crude trexagliptin.

[0020] HPLC purity 98.0%.

Embodiment 2

[0021] The preparation of embodiment 2 Trexagliptin high-quality goods

[0022] Add 10 g of the crude trexagliptin of Example 1, 50 ml of isopropanol, and 10 ml of methyl acetate into the reaction flask, stir and heat to reflux, and slowly dissolve. After dissolving, remove the oil bath, lower the temperature to 0°C to 10°C, keep stirring for 1 hour, filter, and wash the filter cake with isopropanol. Dry in a vacuum oven at 45°C to constant weight to obtain 8.8 g of white solid

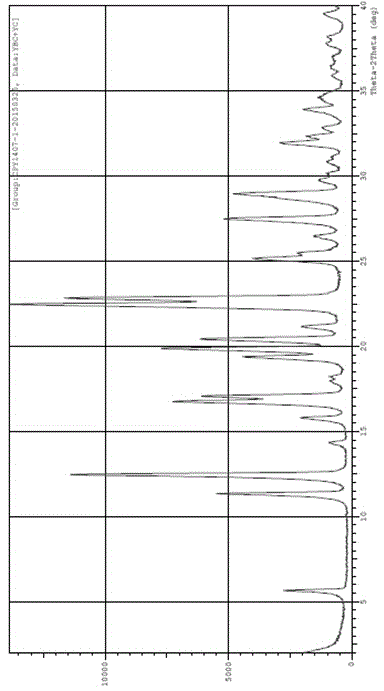

[0023] The yield is 88%, and the HPLC purity is 99.8%. The obtained solid is tested by X-powder diffraction, and the test results are shown in figure 1 .

Embodiment 3

[0024] The preparation of embodiment 3 Trexagliptin high-quality goods

[0025] Add 10 g of crude trexagliptin, 50 ml of isopropanol, and 10 ml of acetonitrile into the reaction flask, stir and heat to reflux, and dissolve slowly. After dissolving, remove the oil bath, lower the temperature to 0°C to 10°C, keep stirring for 1 hour, filter, and wash the filter cake with isopropanol. Dry in a vacuum oven at 45°C to constant weight to obtain 7.7 g of white solid

[0026] Yield 77%, HPLC purity 99.7%, the powder diffraction pattern of white solid and figure 1 Basically the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com