Solid catalyst component for olefin polymerization, and preparation method and application thereof

A solid catalyst and olefin polymerization technology, which is applied in the field of solid catalyst components for olefin polymerization and its preparation and application, and can solve the problems of unfavorable production of high-performance polymers and many defects in PP molecular chains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

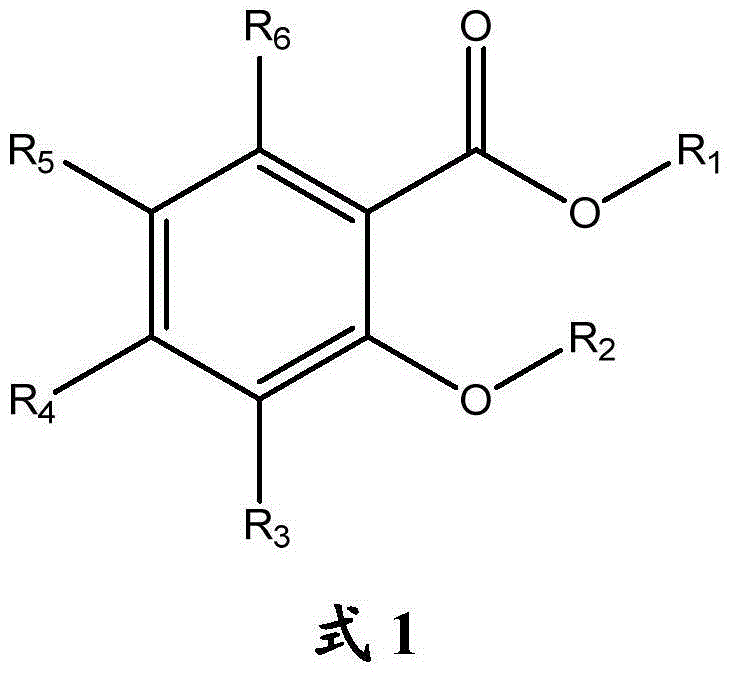

Method used

Image

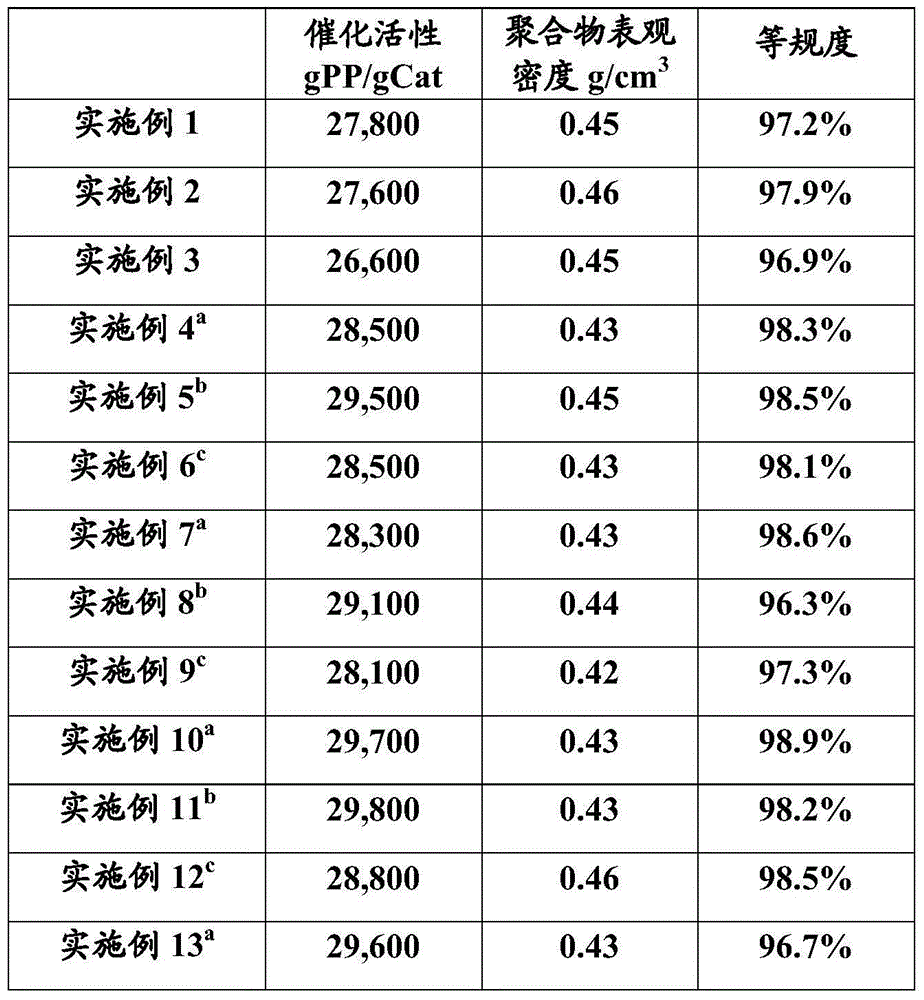

Examples

Embodiment 1

[0076] (1) After fully replacing the flask with a branch tube with nitrogen, add 4.94g of anhydrous magnesium chloride, 18.9g of dried isooctyl alcohol, and 30mL of dried decane, and heat up to 130°C while stirring, and react at this temperature for 2 hours. A homogeneous mixture was obtained. Add 2.65g of tetrabutyl titanate and 1.6g of isobutyl 2-methoxybenzoate to 5ml of toluene in advance, and stir at room temperature for 0.5h to obtain a homogeneous solution. The above homogeneous solution was transferred to the above mixture, and the reaction was continued at 130° C. for 1 hour. After the reaction was completed, it was cooled to room temperature to form a stable and uniform alcoholate solution. Seal all joints with parafilm and place in a desiccator overnight.

[0077] (2) Add the homogeneous alcoholate solution prepared above dropwise into a reactor fully replaced by nitrogen and equipped with 250ml of titanium tetrachloride at -20°C within 1 hour. After the dropwise ...

Embodiment 2

[0084] The reaction bottle with branch tube is fully replaced with nitrogen, add 100ml of titanium tetrachloride to cool down to -20°C, then add spherical particles of magnesium chloride alcoholate within 1h, stir and start to heat up after full contact, when the temperature rises to 60°C Add isobutyl 2-methoxybenzoate with a molar ratio of 0.125:1 to magnesium halide, continue to heat up, and when the temperature rises to 110°C, continue to add 2-methoxybenzene with a molar ratio of 0.125:1 to magnesium chloride Isobutyl formate, and react at this temperature for 2 hours. After the reaction, filter out the liquid, add 100ml of titanium tetrachloride, continue the reaction at 110°C for 2 hours, filter out the liquid, wash with dry hexane, vacuum dried to obtain a solid catalyst component. The molar ratio of titanium tetrachloride and alcoholate is 2.8:1. The molar ratio of the total amount of isobutyl 2-methoxybenzoate to magnesium chloride added twice is 0.25:1. Composition...

Embodiment 3

[0090] The reaction bottle with a branch tube is fully replaced with nitrogen, and 100ml of toluene solvent is added to cool down to 0°C, then ethoxylated magnesium spherical particles are added within 1 hour, and then 50ml of titanium tetrachloride and the molar ratio of ethoxymagnesium to 0.125 are added sequentially: 1 of isobutyl 2-methoxybenzoate, stir until fully contacted and start to heat up, when the temperature rises to 60 °C, add 2-methoxyisobutyl benzoate with a molar ratio of 0.125:1 to magnesium ethoxide Esters, continue to heat up, stop heating when the temperature rises to 110°C, react at this temperature for 2 hours, filter the liquid after the reaction, add 50ml titanium tetrachloride and 100ml toluene solvent, continue the reaction at 110°C for 2 hours hours, the liquid was filtered, washed with dry hexane, and dried in vacuo to obtain a solid catalyst component. The molar ratio of titanium tetrachloride and magnesium ethoxide is 2.8:1. The molar ratio of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com