Cleaning method of gadolinium-gallium-garnet single-crystal substrate for liquid-phase epitaxy

A technology of gadolinium gallium garnet and liquid phase epitaxy, which is applied in the field of cleaning of gadolinium gallium garnet single crystal substrates, can solve the problems of substrate fragmentation, expansion of substrate stress, unfavorable growth of high-quality thin films, etc., and achieve reduction Effects of defects and stress, improvement of film formation rate, and improvement of film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

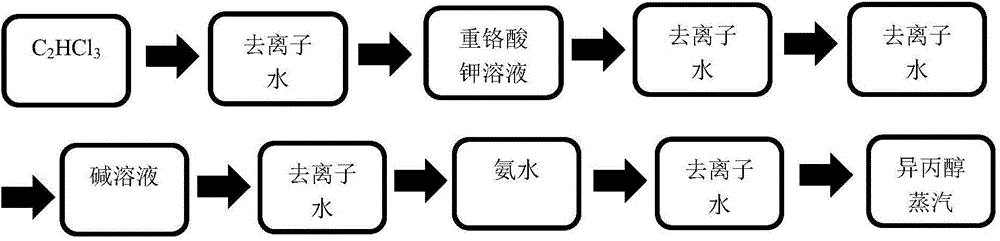

[0025] A method for cleaning a gadolinium gallium garnet single crystal substrate for liquid phase epitaxy, comprising the following steps:

[0026] Step 1: soak the gadolinium gallium garnet single crystal substrate in trichlorethylene at 80°C for 5 minutes to remove organic impurities on the surface of the substrate, and then soak the taken-out substrate in deionized water at 80°C for 5 minutes to remove Trichlorethylene on the surface and impurities in soluble water;

[0027] Step 2: Prepare a mixture of potassium dichromate, concentrated sulfuric acid and water: accurately weigh 19.8g of potassium dichromate and add it to the beaker, then slowly add 100mL of concentrated sulfuric acid to the beaker, stirring continuously during the addition until most of the heavy After potassium chromate dissolves, add 100mL of vitriol oil again, continue to stir heat dissipation, stop until adding 660mL vitriol oil; Then slowly add above-mentioned potassium dichromate acid solution into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com