Method for preparing alpha-AlH3 under control of diisobutylaluminum hydride crystal transformation assistant

A technology of diisobutylaluminum hydride and crystal additives, applied in chemical instruments and methods, metal hydrides, inorganic chemistry, etc., can solve the problem of low yield of α-AlH3

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0019] Specific implementation mode 1: This implementation mode provides a controlled preparation of α-AlH with a diisobutyl aluminum hydride crystal transformation aid 3 The method, the following steps are carried out under anaerobic conditions, the specific steps are as follows:

[0020] (1) AlH 3 Etherate and diisobutylaluminum hydride are dissolved in anhydrous toluene, where each gram of AlH 3 The amount of etherate anhydrous toluene is 70ml, the volume percentage of diisobutylaluminum hydride in anhydrous toluene is 0.5%, and then stirred at 94°C for 2h until the reaction is completed and allowed to stand at room temperature;

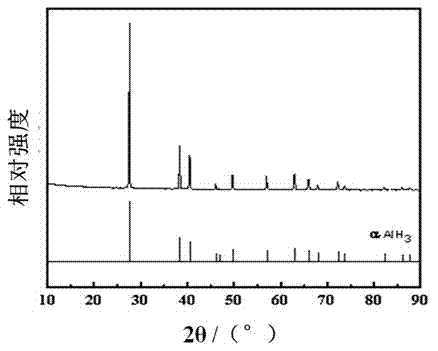

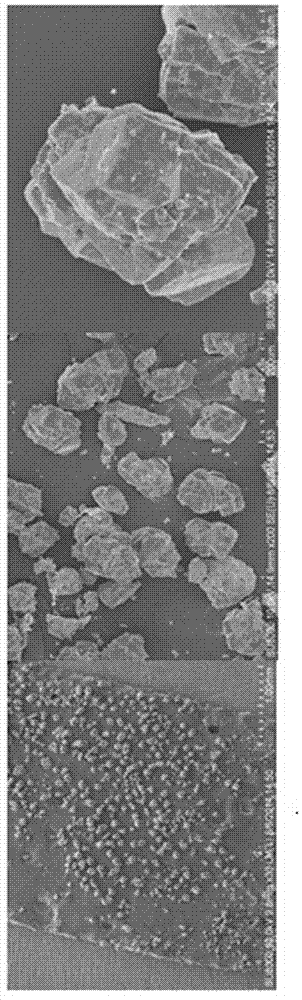

[0021] (2) The white reaction product was obtained by filtration, washed three times with diethyl ether, two times with dilute hydrochloric acid (0.5wt.%), and three times with deionized water, and then dried in vacuum at 60°C for 8 hours at a vacuum degree of 10 Pa. The product was obtained as a white powder. After X-ray diffraction (XRD) and ...

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment is different from Embodiment 1 in that the solvent for crystallization is changed from toluene to benzene.

specific Embodiment approach 3

[0024] Specific implementation mode 3: This implementation mode provides a controlled preparation of α-AlH with a diisobutyl aluminum hydride crystal transformation aid 3 The method, the following steps are carried out under anaerobic conditions, the specific steps are as follows:

[0025] (1) AlH 3 Etherate and diisobutylaluminum hydride are dissolved in anhydrous toluene, where each gram of AlH 3 The amount of etherate anhydrous toluene is 65ml, the volume percentage of diisobutylaluminum hydride in anhydrous toluene is 0.1%, and then stirred at 92°C for 3h until the reaction is completed and allowed to stand at room temperature;

[0026] (2) The white reaction product was obtained by filtration, washed three times with diethyl ether, two times with dilute hydrochloric acid (1wt.%), and three times with deionized water, and then vacuum-dried at 80°C for 6 hours at a vacuum degree of 15 Pa to obtain White powder product. After X-ray diffraction (XRD) and scanning electron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com