Underwater transparent silicon dioxide nanofiber substrate as well as preparation method of substrate and application of substrate to capture of circulating tumor cells

A technology of silica and nanofibers, which is applied in the treatment of tumor/cancer cells, animal cells, fibers, etc., can solve the problems of inability to achieve transparency and meet the requirements of tumor cells, and achieve high detection efficiency and sensitivity, good biological High compatibility and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1: Polyvinylpyrrolidone (PVP) (Mw≈1,300,000) and polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123) are used as structure directing agents. Dissolve 1.5 g of TEOS, 0.5 g of P123, and 1.18 g of PVP in 10 g of ethanol, and stir magnetically at room temperature for 1 hour to obtain a homogeneous solution. A hydrolysis catalyst of TEOS, namely 0.1 g of 2M HCl solution, was added dropwise to the homogeneous solution. It was then heated at reflux at 70 °C for 0.5 h.

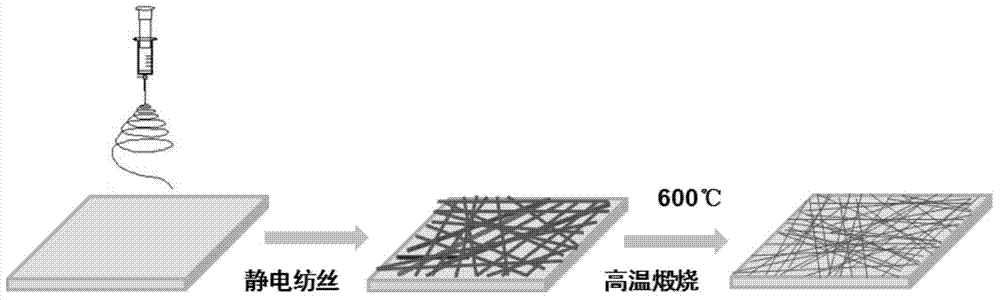

[0028] Step 2: If figure 1 As shown, the spinning voltage is 15kV, the No. 6 needle, the ultra-clean glass sheet is used as the substrate, the substrate is covered with aluminum foil, and the receiving distance is 20cm. The electrostatic spinning process of silica composite nanofibers is carried out. According to the thickness of the spinning fiber , the spinning time was determined to be 45min, and silica composite nanofibers were prepared on the quartz plate substrate. ...

Embodiment 2

[0038] Step 1: polyvinylpyrrolidone (PVP) (Mw≈1,300,000), polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123) as a structure-directing agent. Dissolve 1.5g of TEOS, 0.5g of P123, and 1.18g of PVP in 10g of ethanol, and magnetically stir for 1 hour at room temperature to obtain a homogeneous solution. The TEOS hydrolysis catalyst, i.e. 0.1 g of 2M HNO 3 Was gradually added dropwise to the homogeneous solution. It was then heated at reflux at 75 °C for 0.5 h.

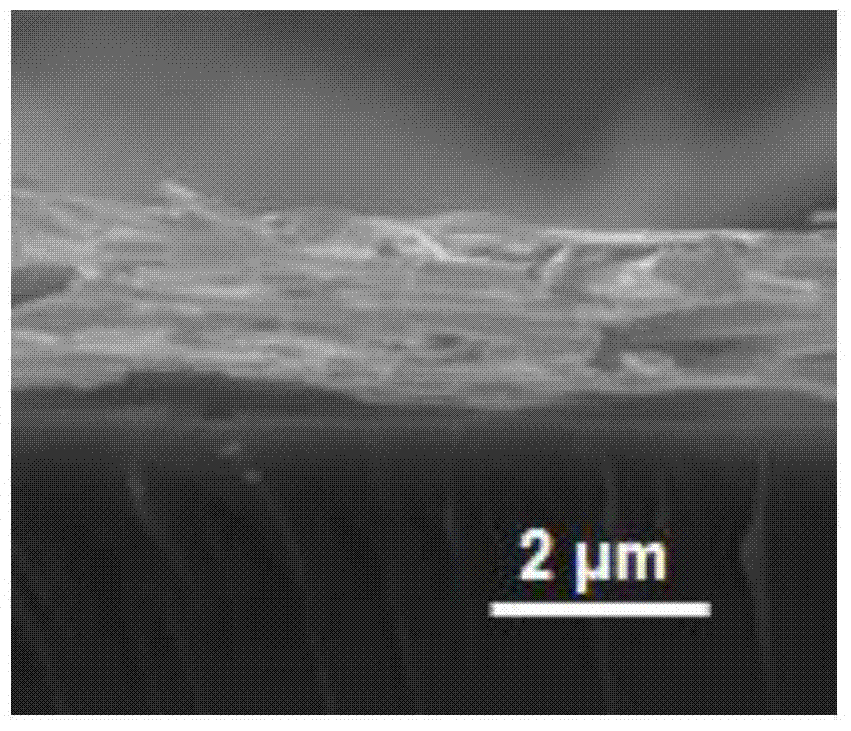

[0039] Step 2: Spinning voltage is 20kV, No. 6 needle, ultra-clean mica sheet is used as the substrate, aluminum foil is placed under the substrate, and the receiving distance is 30cm. The electrospinning process of silica composite fiber is carried out. According to the thickness of the spun fiber, The spinning time was 90 minutes, and a silica composite nanofiber layer with a thickness of 5 μm was obtained.

[0040] Step 3: Place the substrate covered with the silica composite nanofibe...

Embodiment 3

[0048] Step 1: polyvinylpyrrolidone (PVP) (Mw≈1,300,000), polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (P123) as a structure-directing agent. Dissolve 1.5g of TEOS, 0.5g of P123, and 1.18g of PVP in 10g of ethanol, and stir magnetically for 1 hour at room temperature to obtain a homogeneous solution. The hydrolysis catalyst of TEOS, namely 0.1 g of 2M acetic acid, was gradually added dropwise into the solution. The solution was then heated at reflux at 80 °C for 3 h.

[0049] Step 2: Spinning voltage is 30kV, needle No. 6, with ultra-clean quartz sheet as the base, aluminum foil is placed underneath, and the receiving distance is 5cm, and the electrospinning process of silica composite nanofiber is carried out. According to the thickness of the spun fiber, The spinning time was 60 min, and a silica composite nanofiber layer with a thickness of 3 μm was obtained.

[0050] Step 3: Place the substrate covered with the silica composite nanofiber l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com