Cation cross-linked styrene-acrylic surface sizing agent and preparation method thereof

A technology of surface sizing agent and cationic crossover, which is applied in the direction of adding water repellent, can solve the problems of complex production process and high sizing cost, and achieve the effects of improving physical strength, simple preparation method and convenient large-scale promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

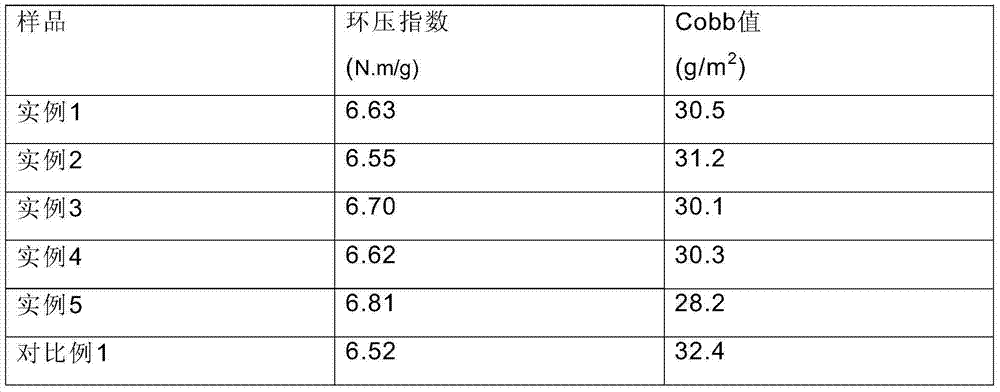

Examples

Embodiment 1

[0027] Get 40g of butyl acrylate, 52g of styrene and 4g of dimethylaminoethyl methacrylate to mix uniformly to obtain a mixed monomer, and set aside; get 50g of corn starch, 300g of deionized water and 5g of paraffin into the reaction kettle, and start Stir and heat up. When the temperature rises to 60°C, add 2g ammonium persulfate, slowly heat up to 88-92°C, and keep warm for 1.5-2h; composition), the above mixed monomer and 5g N-methylolacrylamide, the dropping temperature is 85-88°C, and the dropping time is 1.5-2h; Insulation reaction, after the completion of the insulation, cool down to room temperature, filter through a 300-mesh filter, and obtain a light yellow to light brown-red cationic cross-linked styrene-acrylic surface sizing agent.

Embodiment 2

[0029] Get 45g tert-butyl acrylate, 61g styrene and 4g dimethylaminoethyl methacrylate to mix uniformly to obtain a mixed monomer, and set aside; get 58g wheat starch, 320g deionized water and 8g rosin into the reactor, Start stirring and heat up. When the temperature rises to 60°C, add 2.2g of ammonium persulfate, slowly heat up to 88-92°C, and keep warm for 1.5-2h; 20g of water), the above mixed monomers and 4.5g of glycidyl methacrylate, the dropping temperature is 85-88°C, and the dropping time is 1.5-2h; ~3h heat preservation, after the heat preservation is completed, lower to room temperature, filter through a 300-mesh filter, and then obtain a light yellow to light brown-red cationic cross-linked styrene-acrylic surface sizing agent.

Embodiment 3

[0031] Get 38.5g butyl acrylate, 43g vinyl acetate and 3g dimethylaminoethyl methacrylate to mix uniformly to obtain mixed monomers, set aside; get 63g native tapioca starch, 280g deionized water and 5.6g rosin into the reaction kettle During the process, start stirring and heat up. When the temperature rises to 60°C, add 2g of amylase, slowly raise the temperature to 88-92°C, and keep warm for 1.5-2h; 20g of water), mixed monomer and 5.03g of methacrylic acid, the dropping temperature is 85-88°C, and the dropping time is 1.5-2h; after the dropping, control the temperature at 88-90°C for 2-3h of heat preservation After the heat preservation is completed, lower it to room temperature and filter through a 300-mesh filter to obtain a light yellow to light brown-red cationic cross-linked styrene-acrylic surface sizing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com