Method for cleaning ultrafiltration membrane bag

A technology for ultrafiltration membrane package and cleaning system, applied in ultrafiltration, chemical instruments and methods, membrane technology, etc., can solve the problems of clogging of membrane pores, cumbersome detection of membrane package integrity, membrane package pollution, etc., and achieve the cleaning time. Reduction, excellent cleaning effect, surface tension reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The method (1) of embodiment 1 cleaning ultrafiltration membrane bag

[0032] Take out the new membrane package from the mixed preservation solution of alkali and glycerin, and rinse with purified water to remove the surface alkali solution. Install the cleaned membrane bag into the ultrafiltration fixture, and install pressure gauges at the inlet and return ends respectively to detect the pressure during operation.

[0033] cleaning:

[0034] (1) Alkali-salt mixed liquid circulation cleaning:

[0035] A mixed solution of 0.1 mol / L sodium hydroxide, 5% Tween 80 and 0.25% sodium hypochlorite alkali salt was prepared at a temperature of 40°C. The alkali-salt mixture is connected to the liquid inlet end of the ultrafiltration system through a pipeline, and the pressure of the liquid inlet end of the ultrafiltration system is controlled at 15 psi by controlling the pump speed of the peristaltic pump, and the pressure at the return end is controlled at 2 psi. Ensure that ...

Embodiment 2

[0043]The method (2) of embodiment 2 cleaning ultrafiltration membrane bag

[0044] Take the repeatedly used ultrafiltration membrane package out of the preservation solution and rinse it with purified water. Install the cleaned membrane bag into the ultrafiltration fixture, and install pressure gauges at the inlet and return ends respectively to detect the pressure during operation.

[0045] cleaning:

[0046] (1) Alkali-salt mixed liquid circulation cleaning:

[0047] Prepare 1.0mol / L sodium hydroxide, 3% Tween 80 and 0.3% sodium hypochlorite alkali salt mixture at 30°C. The alkali-salt mixture is connected to the liquid inlet of the ultrafiltration system through a pipeline, and the pressure of the liquid inlet of the ultrafiltration system is controlled at 20 psi by controlling the pump speed of the peristaltic pump, and the pressure at the return end is controlled at 3 psi. Ensure that the pressure at the inlet and return ends is stable within the above pressure range,...

Embodiment 3

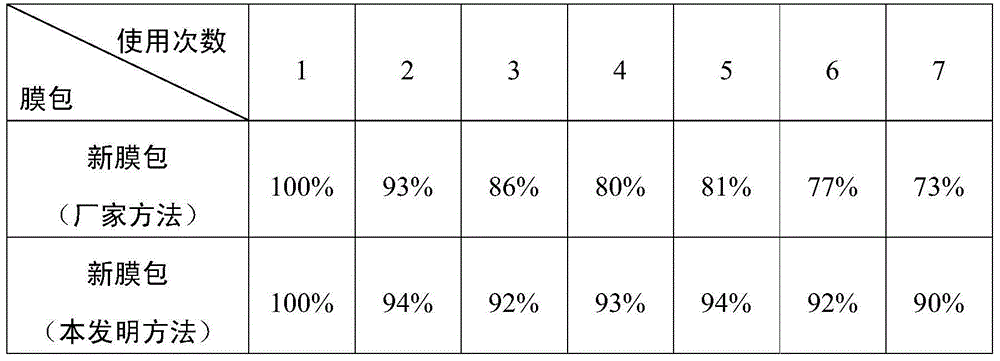

[0055] Using the ultrafiltration membrane bag newly purchased from P company, according to the method of cleaning the ultrafiltration membrane bag guided by the manufacturer and the cleaning method of the present invention, a comparative test is carried out. After each production and use, the ultrafiltration membrane bag is cleaned and the water flow rate is detected. The manufacturer The guidance is that when the water flux of the ultrafiltration membrane is ≥70%, the ultrafiltration membrane can be used continuously, and when the water flux of the ultrafiltration membrane is <70%, it is recommended to discard the ultrafiltration membrane. The comparative test results are shown in Table 1:

[0056] Table 1 The method of the present invention and manufacturer's instruction method clean ultrafiltration membrane bag effect comparison

[0057]

[0058] It can be seen from the above table that the water flux of the new membrane bag after cleaning according to the manufacturer's...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com