High dielectric microwave ceramic dielectric material and preparation method thereof

A technology of microwave ceramics and dielectric materials, applied in the field of high dielectric microwave ceramic dielectric materials and their preparation, can solve the problems of Qf decrease and high sintering temperature, and achieve the effects of simple composition, uniform particle size distribution and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

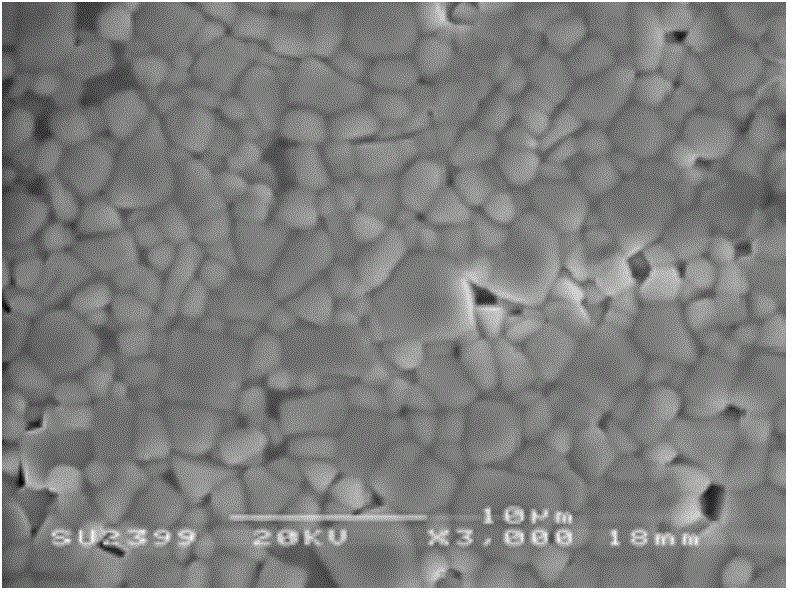

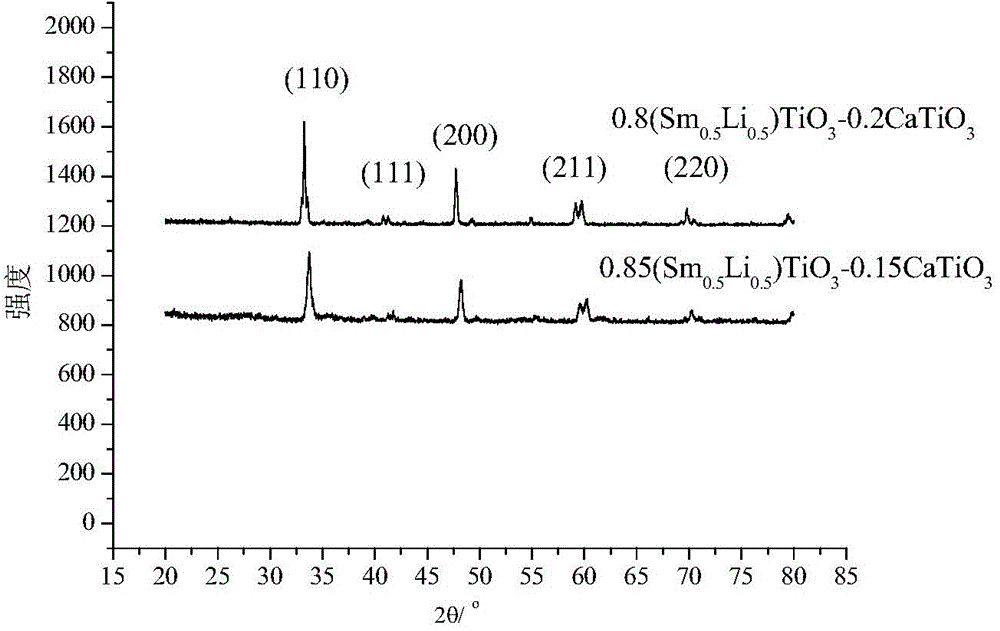

[0023] The chemical formula of the material is 0.85(Sm 0.5 Li 0.5 )TiO 3 -0.15CaTiO 3 , to calculate CaCO 3 , Li 2 CO 3 、Sm 2 o 3 、TiO 2 The ratio of the amount of the substance is 0.15:0.2125:0.2125:1, weigh the CaCO after drying at 180°C 3 , Li 2 CO 3 and Sm dried at 900°C 2 o 3 、TiO 2Each 0.03mol, 0.0425mol, 0.0425mol, 0.2mol, put the ingredients, zirconia balls and propanol in a mass ratio of 1:4:2 into a ball mill jar, wet ball mill in a double-roller ball mill for 16 hours, and the slurry After the material is dried, it is sieved through a 250 μm nylon sieve. The powder is placed in a mullite crucible and covered, and the heating rate is controlled from 5°C / min to 1100°C for 3 hours, and the rate is cooled to room temperature at a rate of 10°C / min. Put the main crystal phase powder, zirconia balls and propanol in a mass ratio of 1:4:2 into a ball mill jar again, wet ball mill in a double-roller ball mill for 16 hours, and pass through a 250 μm nylon sieve a...

Embodiment 2

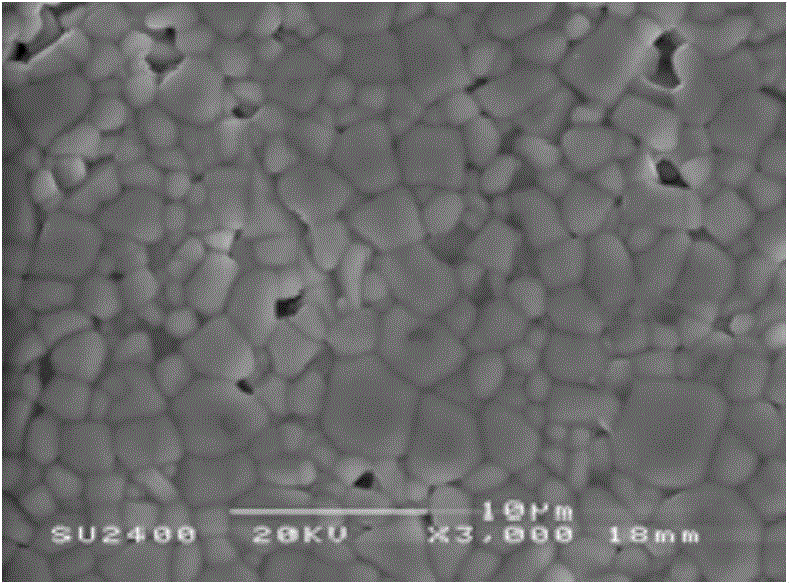

[0026] The chemical formula of the material is 0.8(Sm 0.5 Li 0.5 )TiO 3 -0.2CaTiO 3 , to calculate CaCO 3 , Li 2 CO 3 、Sm 2 o 3 、TiO 2 The ratio of the amount of the substance is 0.2:0.2:0.2:1, weigh the CaCO after drying at 180°C 3 , Li 2 CO 3 and Sm dried at 900°C 2 o 3 、TiO 2 Each 0.04mol, 0.04mol, 0.04mol, 0.2mol. The ingredients, zirconia balls and propanol are put into a ball mill tank at a mass ratio of 1:4:2, wet ball milled in a double-roller ball mill for 14 hours, and the slurry is dried and sieved through a 250 μm nylon sieve. Put it in a mullite crucible and cover it, control the heating rate of 5°C / min to 1095°C for calcination for 3 hours, and cool to room temperature at a rate of 10°C / min. Put the main crystal phase powder, zirconia balls and propanol in a mass ratio of 1:4:2 into a ball mill jar again, wet ball mill in a double-roller ball mill for 14 hours, and pass through a 250 μm nylon sieve after the slurry is dried Sieve, molded under a p...

Embodiment 3

[0029] The chemical formula of the material is 0.82(Sm 0.5 Li 0.5 )TiO 3 -0.18CaTiO 3 , to calculate CaCO 3 , Li 2 CO 3 、Sm 2 o 3 、TiO 2 The ratio of the amount of the substance is 0.18:0.205:0.205:1, weigh the CaCO after drying at 180°C 3 , Li 2 CO 3 and Sm dried at 900°C 2 o 3 、TiO 2 Each 0.036mol, 0.041mol, 0.041mol, 0.2mol. Put the ingredients, zirconia balls and propanol into a ball mill tank at a mass ratio of 1:4:2, wet ball mill for 18 hours in a double-roller ball mill, and sieve the slurry through a 250 μm nylon sieve after drying. Put it in a mullite crucible and cover it, control the heating rate of 5°C / min to 1090°C for calcination for 3 hours, and cool to room temperature at a rate of 10°C / min. Put the main crystal phase powder, zirconia balls and propanol in a mass ratio of 1:4:2 into a ball mill jar again, wet ball mill in a double-roller ball mill for 16 hours, and pass through a 250 μm nylon sieve after the slurry is dried Sieve, molded under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com