Hydrogenolysis catalyst and preparation method thereof

A catalyst, hydrogenolysis technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of high manufacturing cost, environmental pollution, and service life. and other problems, to achieve the effects of stable catalyst composition, improved mass transfer efficiency, and less impurity residues.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

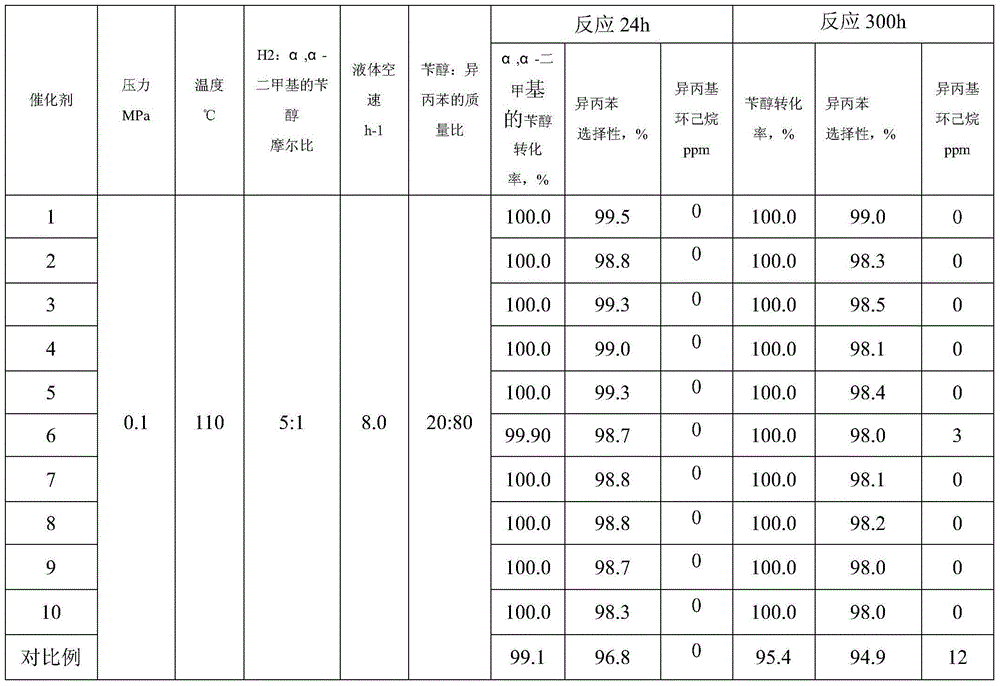

Examples

Embodiment 1

[0031] 2.7g chloroplatinic acid (H 2 PtCl 6 ·6H 2 (2), 776.0g water-soluble phenolic resin with a solid content of 25.0%, 10.0g deionized water, 10.0g nickel nitrate Ni (NO 3 ) 2 ·6H 2 O and 6.1g ammonium molybdate (NH 4 ) 2 MoO 4 Add to the reactor and stir well, with ammonia water NH 3 ·H 2 O adjust the pH to 7.0 and stir for 30 minutes to obtain a homogeneous solution; dehydrate the solution at 40°C and -0.098MPa vacuum for 2h, then dry at 160°C for 3h to obtain a solid mixture of metal salt / phenolic resin, and place the solid mixture in Tube resistance furnace, in N 2 Protection for roasting: heat preservation from room temperature to 500°C for 4 hours at a heating rate of 1°C / min, press the tablet after cooling down, crush and sieve to 20 mesh, and then heat at 150°C, H 2 The hydrogenolysis catalyst 1 was obtained by activating in the atmosphere for 5 hours, and its composition was in parts by weight: 0.5 parts of Pt, 2.5 parts of Ni and Mo (1.0 parts of Ni, 1.5...

Embodiment 2

[0033] 5.4g chloroplatinic acid hexahydrate H 2 PtCl 6 ·6H 2 O, the water-soluble phenolic resin of 30.0% of 640.0g solid content, 15.0g deionized water, 10.0g nickel nitrate Ni (NO 3 ) 2 ·6H 2 O and 11.9 g tin chloride pentahydrate SnCl 4 ·5H 2 O was added to the reactor and stirred well, with ammonia water NH 3 ·H 2 O to adjust the pH to 7.5, and stir for 30 minutes to obtain a homogeneous solution; dewater the solution at -0.080MPa at 90°C for 0.5h in vacuum, then dry at 170°C for 4h to obtain a solid mixture of metal salt / phenolic resin; place the solid mixture in Tube resistance furnace, in N 2 Protection for roasting: raise the temperature from room temperature to 700°C at a heating rate of 2°C / min and keep it warm for 0.5h. After cooling down, press into tablets, crush and sieve to 30 mesh, and then heat 2 Activated in the atmosphere for 4 hours to obtain hydrogenolysis catalyst 2, its composition in parts by weight, 1.0 parts of Pt, 3.0 parts of Ni and Sn (1.0 p...

Embodiment 3

[0035] 8.4g chloroplatinic acid hexahydrate H 2 PtCl 6 ·6H 2 0, 540.0g solid content 35.0% water-soluble phenolic resin, 20.0g deionized water, 12.2g nickel acetate Ni (CH 3 COO) 2 and 10.4g ruthenium chloride trihydrate RuCl 3 ·3H 2 O is added to the reactor and stirred well, with hexamethylenetetramine C 6 h 12 N 4 Adjust the pH to 7.0 and stir for 30 minutes to obtain a homogeneous solution; vacuum the solution at -0.098MPa at 60°C for 5 hours, then dry at 180°C for 5 hours to obtain a metal salt / phenolic resin solid mixture; place the solid mixture in a tube Resistance Furnace, in N 2 Protection for roasting: raise the temperature from room temperature to 750°C at a heating rate of 1°C / min and keep it warm for 5 hours. After cooling down, press into tablets, crush and sieve to 40 meshes, 2 The hydrogenolysis catalyst 3 was obtained by activating in atmosphere for 3 hours, and its composition was 1.5 parts by weight of Pt, 4.0 parts of Ni and Mo (2.0 parts of Ni, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com